Table of Contents

What is cold riveting? cold riveting is a vital connection in modern industrial production. By reading the following, you will learn what is cold riveting, its advantages, applications and the difference between hot riveting and cold riveting.

Table of Contents

What Are the Techniques for Cold Joining Metal?

Cold riveting plays a vital role in the production process of industry. Especially in cases where heat treatment (e.g. welding) is not suitable or permitted. There are several common cold riveting techniques:

- Riveting (joining using rivets)

- Fastening (using bolts, nuts, screws, etc.)

- Adhesive Bonding

- Crimping

- Clamping

- Interference Fit

- Self Piercing Riveting

Each of these cold connection techniques has its own advantages and scope of application. Choosing the right cold jointing technique for a specific application will ensure the strength, durability and reliability of the connection. When using these techniques, care needs to be taken to select the right materials, tools and processes to ensure a precise and standardized operation. Let’s take an in-depth look at rivet cold jointing.

What is Cold Riveting?

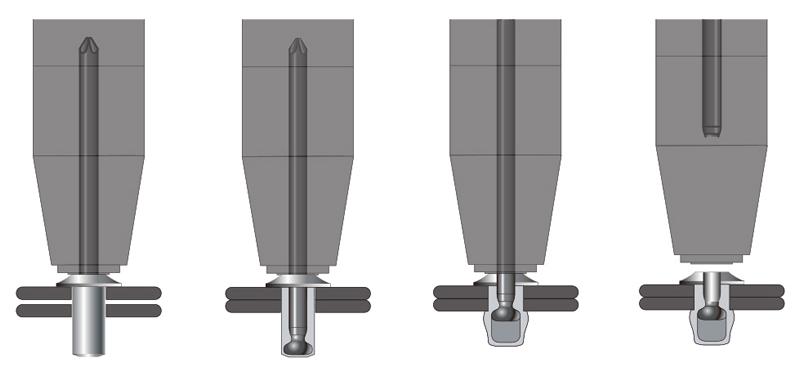

Cold Riveting is a common method of joining metals. It utilizes mechanical forces to plastically deform rivets at room temperature to achieve a permanent connection between metal parts. Unlike hot riveting, cold riveting does not require heating of the rivet or the material being joined. Therefore, no thermal stresses or heat affected zones are introduced.

Cold riveting is the process of pressing a rivet into a pre-drilled hole by applying a mechanical force that deforms the rivet stem and forms a strong connection.

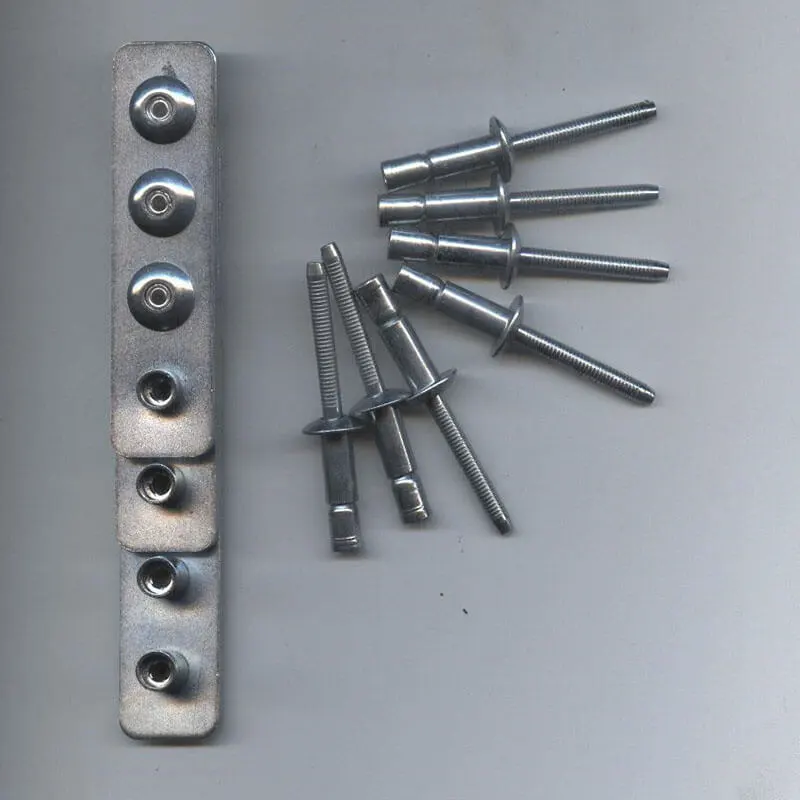

It is important to note that the rivet material is compatible with the metal being joined and it is necessary to ensure that the hole diameter matches the rivet diameter. Avoid holes that are too large or too small to affect the quality of the connection.

What are the Advantages of Cold Riveting?

Cold Riveting is now widely used in various industrial applications. This type of connection has many features and advantages. The following are the main features and benefits of Cold Riveting:

1. No Thermal Effects

Unlike welding, cold riveting does not involve heating. Can effectively avoid the heat treatment caused by the material deformation, thermal stress and performance degradation and other issues. This type of connection can maintain the original mechanical properties of the material to the maximum extent.

2. High Strength and Durability

In actual industrial production, rivets are used in cold riveting to complete the joining process. There are many types of rivets, but not all of them can provide high strength. cold riveting is a method of joining that can provide a high strength mechanical connection, which enables the rivet to withstand high levels of stress and vibration, and ensures the durability and stability of the connection.

3. Easy Operation

The cold riveting process is very simple. Engineers do not need complicated equipment and high temperature treatment for rivet installation. All that is needed is a rivet gun for small repairs and mass production. The field operating costs of the cold riveting process are much lower than other joining methods!

4. No Pollution to the Environment

Unlike other hot riveting methods, the cold riveting process does not produce harmful gases and waste materials, which is in line with environmental requirements. The rivets and materials being joined can usually be recycled, reducing environmental pollution.

5. Low Cost

Why does mass production use a lot of cold riveting? Because the cost of this type of connection is very low! Unlike the hot riveting method, the cold riveting process has a low cost of equipment and low energy consumption during operation, making it suitable for large-scale industrial production and highly cost-effective.

What is Cold Riveting Used for?

Cold Riveting is widely used in many industries and applications where its high strength, durability and ease of operation make it ideal for joining various structures and components. The following are the main application areas and specific examples of Cold Riveting:

Ⅰ. Aerospace Industry

- Aircraft Fuselage and Airfoil: Cold riveting is used to join aircraft fuselages, airfoils and other critical structural components, providing high strength and lightweight connections.

- Aircraft Interior Structures: Used to join seat supports, luggage racks, interior panels, etc. to ensure safety and durability.

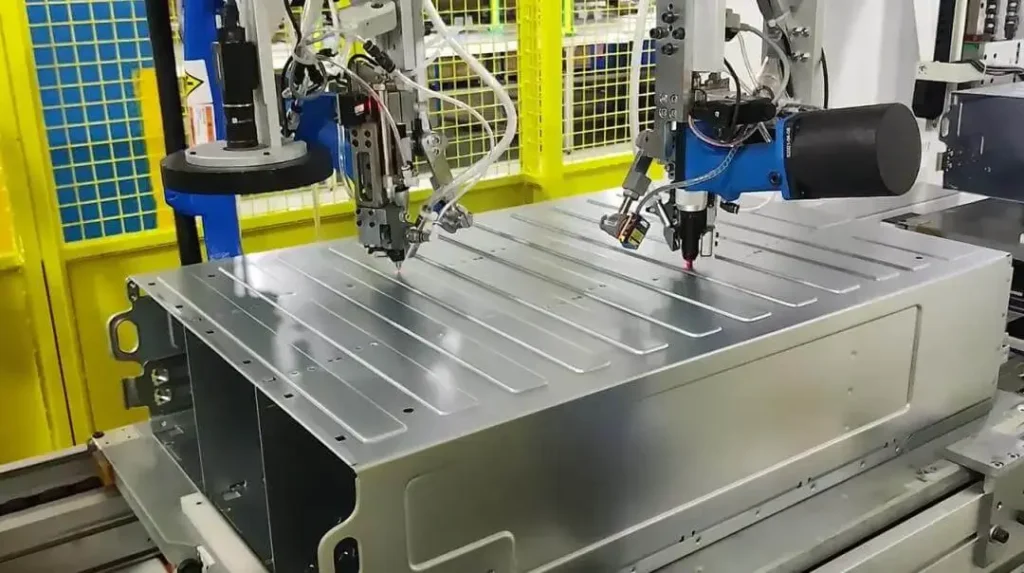

Ⅱ . Automotive Manufacturing

- Body panels: Used to connect exterior panels and interior structural components of the body to provide a strong mechanical connection.

- Chassis and Suspension: Used to connect key components of the chassis and suspension system to ensure the structural strength and safety of the vehicle.

- Doors and Luggage Lids: To connect doors and luggage lids, providing a durable and easy-to-maintain connection.

Ⅲ . Construction

- Bridge Structures: Used for steel connections in bridges, providing high strength and durability of the connection.

- Steel Buildings: for steel connections in high-rise buildings and industrial plants, ensuring structural safety and stability.

- Decorative Connections: used for the connection of architectural decorative parts, providing an aesthetic and flat appearance.

Ⅳ . Shipbuilding

- Hull Structure: Used for the connection of hull plates and frames, providing high strength and corrosion resistant connections.

- Decks and Cabins: Used for connecting internal structural members of decks and cabins to ensure the overall stability of the structure.

- Offshore Equipment: for the connection of offshore drilling platforms and other offshore equipment, providing corrosion-resistant and high-strength connections.

Ⅴ . Home Appliances

- Appliance Housings: Used to connect the metal housings and internal supports of appliances, providing a stable and aesthetically pleasing connection.

- Internal Components: Used to connect various metal components inside the appliance to ensure product stability and durability.

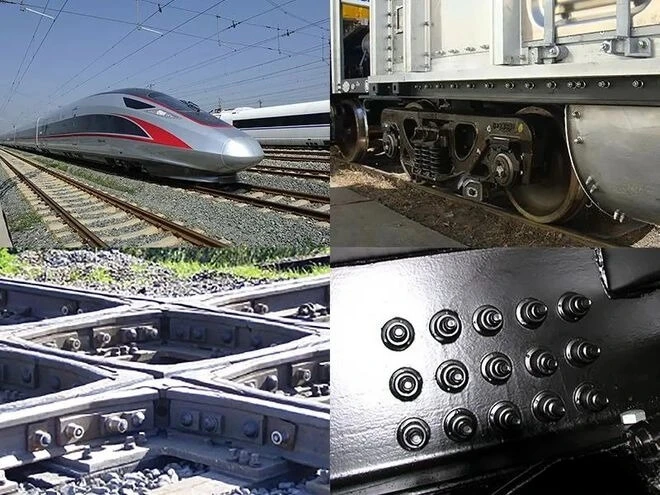

Ⅵ . Railroad and Rail Transportation

- Carriage Structures: Used to connect the outer shell and inner structure of railroad carriages, providing a strong and durable connection.

- Rail Equipment: Used to connect tracks and other rail transportation equipment to ensure safety and stability.

Ⅶ . Heavy Machinery

- Mechanical Frames: Used to connect frame structures of heavy machinery and equipment, providing high strength and durability.

- Moving Parts: Used to connect moving parts and brackets of heavy machinery to ensure operational stability.

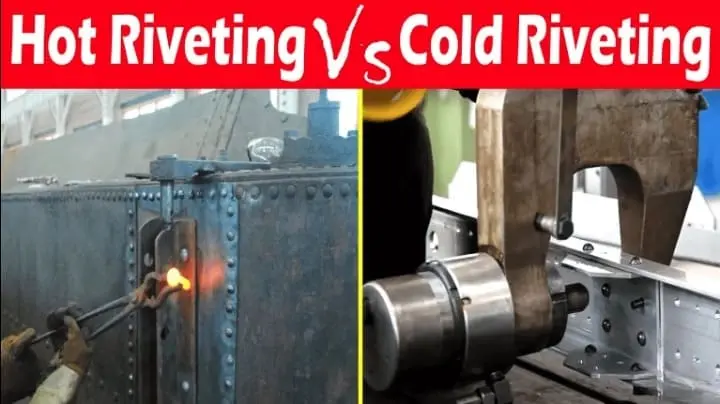

What is the Difference Between Hot Riveting and Cold Riveting?

Hot Riveting and Cold Riveting are two common riveting techniques. There is still a big difference between them. There are significant differences in the principles, processes, applications, advantages and disadvantages. hot riveting provides a stronger joint, good filler and eliminates residual stresses. cold riveting is simple to perform and is well suited for on-site and mass production. cold riveting does not affect the material properties and does not contaminate the environment.

Hot riveting is suitable for heavy structures and highly stressed components where high strength and durability are required. It provides a very strong connection despite the higher cost and complexity of operation. Cold riveting, on the other hand, is more suitable for mass production and joining metals at room temperature. Easy to operate and environmentally friendly, it is suitable for automotive manufacturing, household appliances and general metal construction. The choice of riveting method should be based on the specific needs of the application, material properties and economic costs to be considered in a comprehensive manner.

Hot Riveting vs Cold Riveting

| Feature | Hot Riveting | Cold Riveting |

| Principle | Rivet is heated to a red-hot state, then riveted. Upon cooling, it shrinks and tightly clamps the material. | Rivet is deformed and fixed at room temperature by applying mechanical force. |

| Process | 1. Heat the rivet 2. Insert the rivet 3. Rivet and form 4. Cool | 1. Drill holes 2. Insert the rivet 3. Apply pressure |

| Advantages | 1.Provides high-strength connection 2.Good filling properties 3.Eliminates some residual stress | 1.Simple operation 2.No thermal impact 3.Environmentally friendly |

| Disadvantages | 1.Requires high-temperature equipment 2.May affect material properties 3.Environmental and safety risks | 1.Limited applicability 2.Possible residual stress |

| Applications | 1.Heavy structures (bridges, steel buildings, large machinery) 2.High-stress components (aircraft, ships) | 1.Automotive manufacturing (body panels, chassis) 2.Household appliances 3.General metal structures |

| Economics & Efficiency | 1.Higher cost 2.Lower efficiency | 1.Lower cost 2.Higher efficiency |

| Environmental Impact | High-temperature operation may produce waste gases and thermal pollution | No waste gases and thermal pollution produced |

Conclusion

As technology continues to evolve and manufacturers seek faster, less costly methods of production, Cold riveting has become the perfect choice for manufacturers. Today, cold riveting plays a vital role in industrial manufacturing. And with the ability to adapt to many different applications and materials, blind rivets can solve most of your thin sheet assembly problems.

Save Time and Money with Rivmate Blind Rivet !

Rivmate is a leader in the riveting systems industry. Our years of experience and dedication to quality allow us to manufacture the best blind rivet for your project.Rivmate Cold Riveting Solutions can meet all of your thin sheet joining needs.

We offer sample service and free quotes for new customers. We help them to fulfill their orders quickly.

Start saving money with Rivmate. Contact us today!