Home » Rivmate-Pneumatic Tool for blind rivet and nut » Pneumatic Pop Rivet Gun – C Series Blind Rivet Tool

RIVMATE Pneumatic Pop Rivet Gun Tool

Rivmate Pneumatic Pop Rivet Gun

Specifications of Pneumatic Pop Rivet Gun

| Pull Force | >18.68KN |

| Stroke | 17mm - 28mm |

| Standard Pressure | 0.55MPa - 0.6MPa |

| Air Presure | 0.5 - 0..7MPa |

| Vacuum | Y |

| Weight | 1.45Kg - 1.64Kg |

| Size | 276×312×119/134mm |

| Rivet Material | All Material |

| Compatible Rivets | 2.1mm,3.2mm,4.0mm,4.8mm |

| (3/32",1/8",5/32",3/16") | |

| Noise Level | <75dB(A) |

Details of Pneumatic Blind Pop Rivet Gun

Pneumatic pop rivet gun can be a huge labor cost saver. If you have a need for rivet guns, please understand to contact us.

Original Guide Nozzle

Three-Piece Jaws

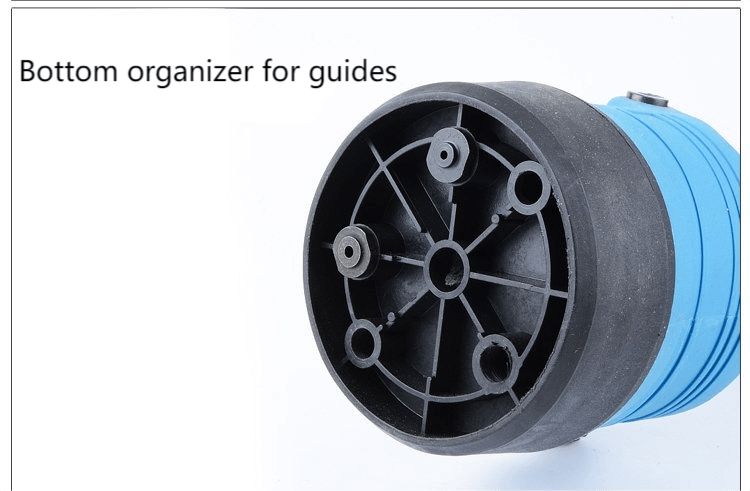

Bottom Organizer for Guides

Starter Switch

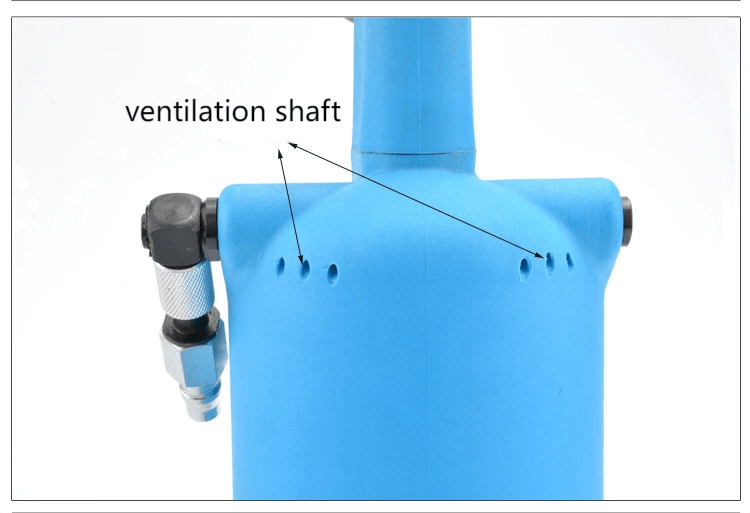

Ventilation Shaft

Inlet

Nail Collection Bottle

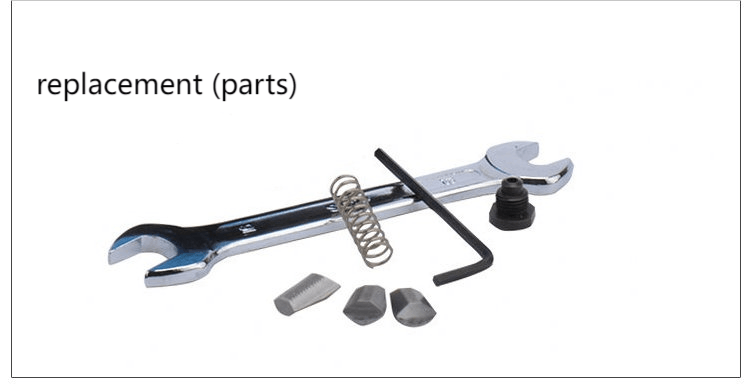

Replacement

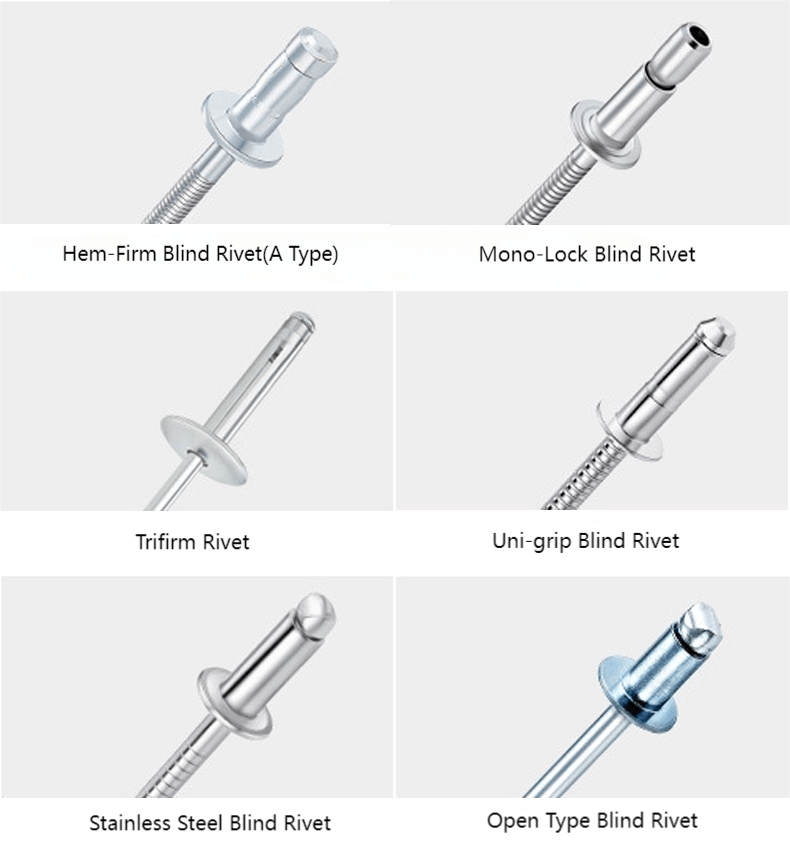

Suitable for a variety of blind rivets

Pneumatic Blind Pop Rivet Gun is designed to improve the efficiency of riveting. Helping the success of industrial projects.

C Series blind rivet gun can be used for all common blind rivets.

Multi-specification guide configurations

A pneumatic rivet gun. Easy to deal with a variety of want good rivets

Caveat

When buying a rivet gun must check the parameters of the rivets, and then choose the corresponding pneumatic rivet gun.

Please apply blind rivets correctly!

How to maintain the pneumatic blind pop rivet gun?

Maintenance is better than repair!

The key to improving the life of your machine is to maintain it properly.

- Add a few drops of maintenance oil to the air inlet before and after using the pneumatic rivet gun.

- Then idle the rivet gun.

This will extend the life of the pneumatic rivet gun as long as possible. The fewer failures there will be as well.

C Series Pneumatic Blind Rivet Tool

C848 Blind Rivet Tool

| Pull Force | Stroke | Standard Pressure | Air Pressure | Noise Level | Vacuum |

| >9KN | 17mm | 0.55MPa | 0.5-0.7MPa | <75dB(A) | Y |

| Weight | Size(L*H*W) | Rivet Material | All Material | ||

| 1.45Kg | 276*312*119mm | Compatible Rivets | 2.4mm,3.2mm,4.0mm,4.8mm(3/32",1/8",5/32",3/16") | ||

C864 Monolock Rivet Tool

| Pull Force | Stroke | Standard Pressure | Air Pressure | Noise Level | Vacuum |

| >14.68KN | 28mm | 0.55MPa | 0.5-0.7MPa | <75dB(A) | Y |

| Weight | Size(L*H*W) | Rivet Material | All Material | ||

| 1.64Kg | 276*312*134mm | Compatible Rivets | 2.4mm,3.2mm,4.0mm,4.8mm(3/32",1/8",5/32",3/16") | ||

C866 Hemlock Rivet Tool

| Pull Force | Stroke | Standard Pressure | Air Pressure | Noise Level | Vacuum |

| >18.68KN | 17mm | 0.6MPa | 0.6-0.7MPa | <75dB(A) | Y |

| Weight | Size(L*H*W) | Rivet Material | All Material | ||

| 1.64Kg | 276*312*134mm | Compatible Rivets | 4.8mm-6.4mm(3/16"-1/4") | ||

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com

CONTACT PERSON SEARCH

Warranty Statement on C Series Pneumatic Pop Rivet Gun

The installation tools carry a 12 month warranty against defects caused by faulty materialsor workmanship, the warranty period commencing from the date of delivery confirmed byinvoice or delivery note.

The warranty applies to the user/purchaser when sold through an authorised outlet, andonly when used for the intended purpose.The warranty is invalidated if the installation toolis not serviced, maintained and operated according to the instructions contained in theInstruction and Service Manuals.

In the event of a defect or failure, and at its sole discretion, undertakes only to repairor replace faulty components.

Safety rules to which persons installing, operating or servicing Pneumatic Pop Rivet Gun must pay special attention

Do not use outside the design intent

Do not use equipment with this too/machine other than that recommended and supplied by tool.

Any modification undertaken by the customer to the tool/machine, nose assemblies, accessories or any equipment supplied by

tool or their representatives, shall be the customer’s entire responsiblity. we will be pleased to advise upon any proposed modification

The tool/machine must be maintained in a safe working condition at all times and examined at regular intervals for damage and function by trained competent personel.Any dismanting procedure shall be undertaken only by personnel trained in tool procedures.Do notdismantle this too/machine without prior reference to the maintenance instructions.Please contact us with your training requirements.

The tool/machine shall at all times be operated in accordance with relevant Health and Safety legislation.Any question regarding the correct operation of the tool/machine and operator safety should be directed to us.

The precautions to be observed when using this tool/machine must be explained by the customer to all operators

Aways disconnect the airline frorm the tool/machine inlet before attempting to adjust, fit or remove a nose assembly.

Do not operate a tool/machine that is directed towards any person(s) or the operator.

Always adopt a firm footing or a stable position before operating the too/machine

Ensure that vent holes do not become blocked or covered.

The operating pressure shall not exceed 7 bar.

Do not operate the toolif it is not fitted with a complete nose assembly or swivel head unless specifically instructed otherwise.

Care shall be taken to ensure that spent stems are not allowed to create a hazard.

if the tool is fitted with a stem collector,it must be emptied when half full.

lf the tool is ftted with a stem defector it should be rotated until the aperture is facing way from the operator and other personls) working in the vicinity.

When using the tool, the wearing of safety glasses is required both by the operator and others in the vicinity to protect against fastener ejection, should a fastener be placed ‘in air. We recommend wearing gloves if there are sharp edges or corners on the application.

Take care to avoid entanglement of lose clothes, ties, long hair,cleaning rags etc.in the moving parts of the tool which should be kept dry and clean for best possible grip.

when carying the tool from place to place keep hands away from the trigger/lever to avoid inadvertent start up.

Excessive contact with hydraulic fuid oil should be avoided. To minimize the possibility of rashes, care should be taken to wash thoroughly.

Pneumatic Pop Rivet Gun Requirements for Air Pressure

Pneumatic pop rivet guns are operated with compressed air at an optimum pressure of 5.5 bar. We recommend the use of pressure regulators andautomatic ollingitering systems on the main air supply. These should be ftted within 3 metres of the tool (see diagram below)to ensure maximum tool life and minimum tool maintenance.

Air supply hoses should have a mininum working effective pressure rating of 150% of the maximum pressure produced in the system or10 bar, whichever is the highest. Air hoses should be ail resistant,have an abrasion resistant exterior and should be armoured whereoperating conditions may result in hoses being damaged. Al ir hoses MUST have a mininum bore diameter of 6.4 milimetres or 1/4 inch.