Blind Rivet Grip Range Chart

The Blind Rivet Clamping Range Comparison Chart is a key piece of technical information used to select the appropriate riveting thickness. This technical table shows the total range of material thicknesses that can be clamped by each size of rivet to ensure that the rivet will deform correctly and securely hold the joint during installation.

| Rivet Diameter (inch) | Rivet Diameter (mm) | Grip Range (mm) | Recommended Hole Size (mm) | Typical Application |

|---|---|---|---|---|

| 3/32″ | 2.4 mm | 0.5 – 2.0 mm | 2.5 – 2.6 mm | Precision devices, plastic shells |

| 1/8″ | 3.2 mm | 0.5 – 3.0 mm | 3.3 – 3.4 mm | Home appliances, electronics |

| 5/32″ | 4.0 mm | 1.0 – 4.5 mm | 4.1 – 4.2 mm | Automotive interiors, panels |

| 3/16″ | 4.8 mm | 1.5 – 6.0 mm | 4.9 – 5.0 mm | Sheet metal, equipment chassis |

| 7/32″ | 5.6 mm | 2.0 – 7.0 mm | 5.7 – 5.8 mm | Enclosures, control cabinets |

| 1/4″ | 6.4 mm | 2.5 – 9.5 mm | 6.5 – 6.6 mm | HVAC ducts, outdoor equipment |

| 9/32″ | 7.1 mm | 3.0 – 10.0 mm | 7.2 – 7.3 mm | Pressure vessels, machine frames |

| 5/16″ | 7.9 mm | 4.0 – 12.5 mm | 8.0 – 8.1 mm | Steel structures, enclosures |

| 3/8″ | 9.5 mm | 5.0 – 16.0 mm | 9.6 – 9.8 mm | Heavy-duty joints, structural supports |

✅ Additional Notes:

- The data listed is for standard open end blind rivets. For structural, sealed or Multi-Grip rivets, the clamping range will be extended.

- The hole diameter is recommended to be slightly larger than the body diameter of the rivet by 0.1-0.2 mm to ensure smooth installation and adequate clamping force.

- Special applications (e.g., high-strength shear, automated riveting, soft material bonding) should be evaluated to determine if a customized clamping range is required.

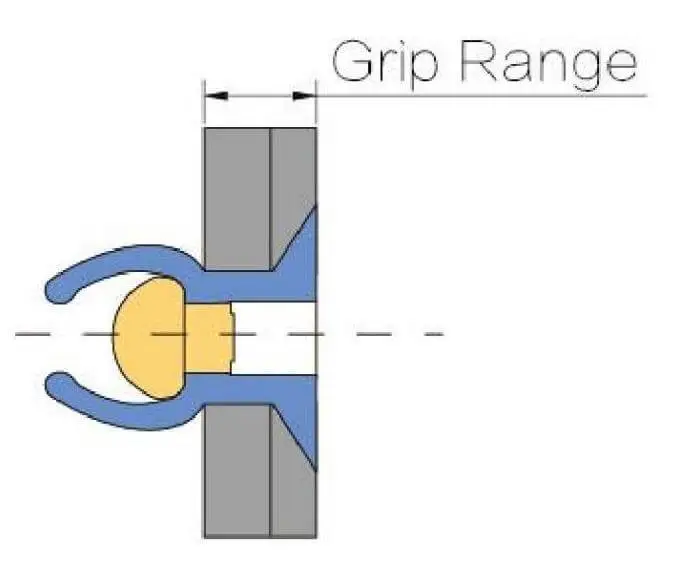

what is the blind rivet grip range?

Blind Rivet Grip Range is the range of total material thickness that a blind rivet can effectively clamp during installation, usually expressed in millimeters (mm) or inches (inch). If a rivet is labeled Grip Range: 1.5 – 3.0 mm, it can be used in situations where the total thickness of the two pieces of material combined is between 1.5 mm and 3.0 mm. It should not be used on structures that are only 1.2 mm thick or greater than 3.0 mm thick.

how do i know if a rivet's grip range fits my application

You can follow these steps to determine if the clamping range of a blind rivet is suitable for your application.

- Accurately measure total material thickness: Use calipers to measure the total thickness of all riveted parts, including coatings, shims, etc. 2. Check the Grip Range of the rivet specification.

- Check the Grip Range of the rivet specification: Each rivet model is labeled with a minimum-maximum grip thickness. Make sure your total thickness falls within this range.

- Avoid Limits (Upper and Lower Boundaries): The actual thickness recommended for use falls in the middle of the Grip Range. For example, if your material thickness is 1.5 mm, you should consider rivets with a 0.8-2.5 mm or 1.0-3.0 mm clamping range, rather than just the 1.5 mm starting point.

- Check that the hole size matches: holes that are too large or too small can affect clamping force and rivet formation, so refer to the recommended blind rivet hole size range chart.

what happens if my material stack is outside the rivet grip range?

📉 If the material thickness is below the clamping range (too thin):

The rivet does not have enough “resisting” thickness to form a stable counter tension when it expands, resulting in insufficient clamping force. The result may be a rivet that does not pull tightly on the material, wobbles, fails to rivet securely, or even slips out of place due to vibration or loading during use. In addition, the appearance may be poor, and the rivets appear skewed or misaligned, seriously affecting the precision and reliability of product assembly.

📈 If the material thickness exceeds the clamping range (too thick):

The rivet may not be able to insert into the full material layer at all, or the mandrel may break, the rivet may not be molded, and the clamping may fail due to insufficient expansion space during the riveting process. This not only loosens the connection, but can also damage the assembly tooling, causing production stoppages or increased rework, especially at higher risk in automated assembly lines.

how do i choose the right grip range when thickness varies?

Practical selection steps:

- Determine the total assembled thickness range: for example, from 4.8 mm to 6.2 mm after sheet stacking.

- Find the Grip Range in the Rivet Specification Sheet: For example, the common grip ranges for a 4.8 mm blind rivet are as follows: 3.0-4.5 mm, 4.0-6.0 mm, 6.0-8.0 mm.

- Select a Grip Range that fully covers this thickness range.

In the example above, a model in the 6.0-8.0 mm range should be selected because 4.0-6.0 mm does not provide complete coverage of the maximum assembly thickness of 6.2 mm.

is blind rivet grip range the same as rivet length?

The actual length of a blind rivet is always greater than its maximum clamping thickness because the tail of the rivet needs to be left open for deformation molding. A blind rivet with a nominal diameter of 4.8 mm and a clamping range of 4.8-6.4 mm may have an overall length of 10 mm, 12 mm or even longer, depending on the amount of allowances for deformation required by the design. You should not extrapolate the rivet length from the assembled thickness alone, but must consult the Technical Data Sheet of the product.

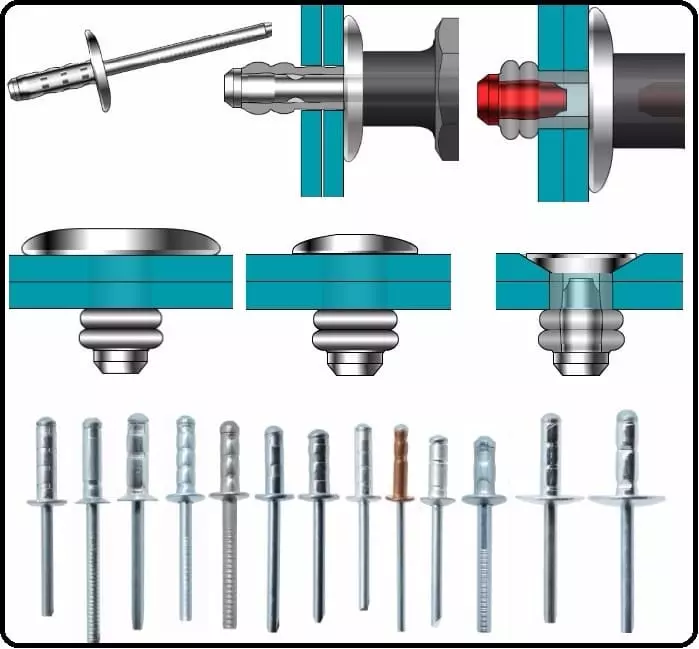

do structural rivets have different grip ranges?

Structural rivets have a wider clamping range than ordinary blind rivets.

Many structural rivets utilize a “multi-stage deformation” or “locking core design” to accommodate a wide range of plate thicknesses. A single model may cover a thickness of 4.8-9.5 mm, much greater than the 1.5-2.0 mm range of common rivets.

Structural rivets are used in structures with high load, vibration or shear requirements, such as shelving, heavy equipment, and automotive chassis. In order to ensure consistent clamping force, their clamping range is strictly verified and cannot be arbitrarily exceeded.

how close to the edge of the blind rivet grip range can i operate?

There is a potential risk when the riveted thickness lies just above and below the upper and lower limits of the clamping range (either minimum or maximum). This situation is a critical use and is not in line with best engineering practice.

Conclusion

The Blind Rivet Grip Range chart is a critical tool in rivet selection to ensure that rivets are selected for reliable clamping and deformation within the actual assembly thickness.

Accurately matching the grip range not only protects the strength and long-term stability of the riveted joint, but also avoids the risk of failure due to molding defects, mandrel slippage or insufficient clamping force. The Blind Rivet Grip Range Chart is therefore a central tool for ensuring assembly quality, structural safety and production consistency.