PPAP Rivets Manufacturing Process

Home » PPAP

The PPAP documentation package is certified by both us and the customer.The purpose of the PPAP documentation is to reduce the risk of unintended failures due to errors in involving or manufacturing. Our factories can provide PPAP documentation to our customers.

The levels of PPAP documentation that we can customer provide include the following levels:

- Level 1: Only Part Submission Warrant (PSW) is provided to the customer.

- Level 2: Provide Part Submission Warrant, product samples, and partial supporting data.

- Level 3: Provide Part Submission Warranty, product samples, and complete supporting data.

- Level 4: Provide the part submission warranty and other customer-defined requirements.

- Level 5: Supplier is required to have the part submission warranty, samples, and complete supporting data available at the manufacturing site for verification purposes.

Below are 19 documents from PPAP:

- Design Records

- Authorized Engineering Change (note) Documents

- Engineering Approval

- DFMEA

- Process Flow Diagram

- PFMEA

- Control Plan

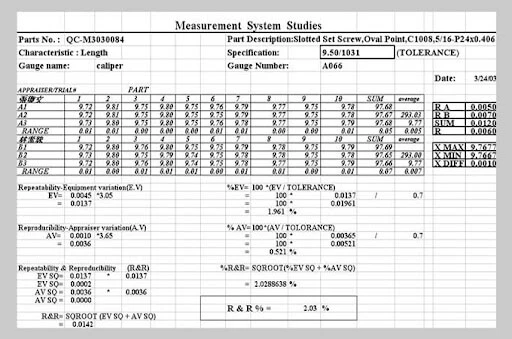

- Measurement Systems Analysis、MSA

- Dimensional Results

- Records of Material / Performance Tests

- Initial Sample Inspection Report

- Initial Process Studies

- Qualified Laboratory Documentation

- Appearance Approval Report

- Sample Production Parts

- Master Sample

- Checking Aids

- Customer-Specific Requirements

- Part Submission Warrant、PSW

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

Room 9016 of 2# Building, No. 436 Changjiang Road, Suzhou City, Jiangsu Province, China 215011

+86 189 6230 4392

or write

manufacture@world-rivet.com