You should know about huck bolt vs rivet to start a new project. Learn the difference between huck bolt and rivet and build the most correct riveting system.

What is a Huck Bolt?

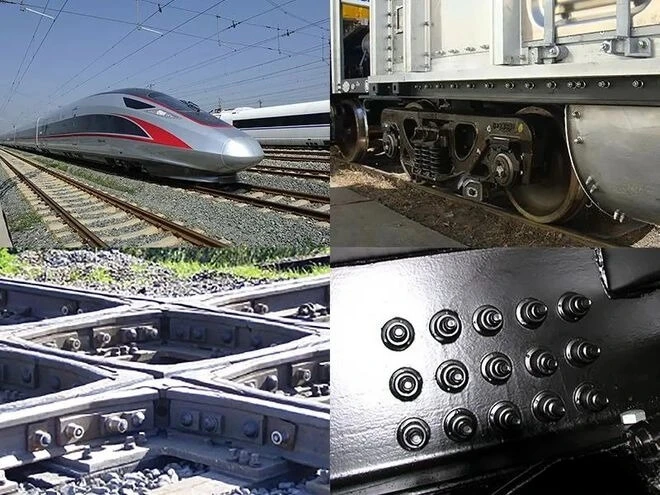

The Huck Bolt is a high-strength mechanical fastener used in a wide range of applications in heavy-duty and high-vibration environments such as construction, bridges, railroads, trucks, and other heavy equipment.The Huck Bolt system consists of two main components: a bolt and a locking ring (or collar).

When your project requires exceptional strength, choose the huck bolt to complete the joining process. the huck bolt provides extremely high tensile and shear strength, and the unique mechanical locking involved prevents loosening and dislodging. the huck bolt is designed for use in a wide variety of applications, such as construction bridges, railroads, and other heavy-duty equipment.

What is a Rivet?

A rivet is a permanent mechanical fastener. It can be used on many different materials. Blind rivets can join dissimilar metals, but of course care needs to be taken to ensure compatibility between the metals.

The most important feature of blind rivets is that they can be riveted on one side. As a result, blind rivets are now widely used in a variety of different applications. Whether it is a light duty application or a heavy duty application, you can find the right type of rivet for them in a blind rivet.If you want an in-depth look at the types of rivets and their applications. Please read my article “types of rivets and their application“.

Pros and Cons of Huck Bolts

Now let’s take a look at the pros and cons of huckbolts.

Pros of Huck Bolt

Huck bolt is an ultra-high strength riveted fastener that offers several advantages. Here are some of the advantages of huck bolt:

- Huck Bolt offers extremely high tensile and shear strength to withstand heavy loads and high stress environments.

- The mechanical locking design prevents loosening and dislodging and is especially suited for high vibration and dynamic load applications such as railroads and trucks.

- Installation is quick and easy with a specialized Huck Bolt installation tool, eliminating the need for complicated maneuvers.

- No precise torque control is required during installation, avoiding over-tightening or over-loosening problems.

- Consistent mounting results for each Huck Bolt ensures the same tightening force at each connection point.

- Provides a reliable connection and reduces the need for maintenance.

- Huck Bolt is manufactured using high quality materials to ensure long term performance in harsh environments.

- Suitable for outdoor and wet environments for extended life.

- Because the Huck Bolt will not loosen, it reduces the need for periodic inspection and retightening, reducing maintenance costs.

Cons of Huck Bolt

Of course, no fastener is perfect.The Huck bolt has a number of drawbacks in addition to its many advantages. Here are some of the disadvantages of huck bolts:

- The high initial cost of the Huck Bolt and its specialized installation tools can pose a challenge for smaller projects or those with limited budgets.

- Huck Bolts are often made from high strength materials, which can be costly.

- Specialized Huck Bolt installation tools (hydraulic or pneumatic tools) are required, which adds to the cost of the equipment and operational complexity.

- Installation tools require regular maintenance and specialized training for operators.

- The installation process of the Huck Bolt makes it a permanent connection that cannot be reused after removal, limiting its use in applications that require frequent disassembly and reassembly.

- Because the Huck Bolt is typically made of high-strength metals, it may increase the total weight of the connected structure, which may be detrimental in certain applications where lightweighting is critical.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Pros and Cons of Rivets

As an engineer, there is definitely a basic understanding of rivet, but recognizing its pros and cons is still necessary.

Pros of Rivets

A rivet is a widely used riveted fastener that is used in many industries. It can connect a variety of items for you. Here are some of the benefits of rivets:

- Rivets provide a strong and durable mechanical connection for applications subject to high stress and vibration.

- Rivets form a connection that will not easily loosen or fall out, ensuring structural stability and safety.

- Rivets are suitable for joining a wide variety of materials, including metals, plastics and composites.

- They are widely used in aerospace, construction, automotive manufacturing, marine and electronic equipment.

- The riveting process is simple and fast, especially suitable for mass production and automated assembly lines.

- It can be operated flexibly with a variety of tools such as manual rivet guns, pneumatic rivet guns and hydraulic riveting machines.

- Rivets are suitable for joining thin sheet materials without threading, simplifying the production process.

- Rivet connection does not apply high pressure to the material like bolting, which reduces the risk of material deformation.

- The riveting process does not produce harmful gases and waste materials, in line with environmental requirements.

- Compared with welding and other high-temperature joining methods, riveting uses less energy.

Cons of Rivets

Rivets also have some drawbacks. Here are some of the disadvantages of rivets:

- Once riveted, the riveted joint is usually not removable; if removal is required, the rivets must be destroyed, making repairs and modifications to the structure more difficult.

- Riveting may not be as effective as other fastening methods for materials with high hardness or thickness.

- The strength of rivets is mainly concentrated at the connection point, if the number of rivets is insufficient or unevenly distributed, it may lead to a lack of local strength.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Huck Bolt vs Rivet: What's the Difference?

Huckbolt and rivet have many similarities, but they are also very different from each other. Here are the main differences between huckbolt and rivet:

| Point of Difference | Huck Bolt | Rivet |

| devise | Consisting of a bolt and a locking ring (collar), the tail is locked and sheared by means of a special tool. | Consisting of a nail shank and a nail head, a connection is formed by deforming the nail shank with a riveting tool. |

| connection strength | Provides extremely high tensile and shear strength for heavy loads and high vibration environments. | Provides a high-strength connection, but not as strong as Huck Bolt’s tensile and shear strength. |

| Durability and reliability | High durability with excellent resistance to vibration and dynamic loads, reducing the risk of loosening and dislodging. | Good durability, but may require more maintenance in high vibration environments. |

| application scenario | Suitable for heavy vehicles, railroads, buildings, bridges, mining equipment and other highly loaded structures. | Widely used in aerospace, construction, automotive manufacturing, marine, electronic equipment and so on. |

| costs | Initial costs are high and include high material costs and specialized tooling costs. | Relatively low initial cost and suitable for high volume production. |

1. Devise

Huckbolt and rivet are very different in their structural design although they work on similar principles.Huckbolt consists of a bolt and collar which is locked and sheared off at the end by a special tool.Rivet consists of a nail and a nail head which is deformed and squeezed to form a joint by a riveting tool.Huckbolt is made by a special tool which is used to lock and shear the tail.

2. Connection Strength

Another big difference is that their connection strengths vary greatly.Huckbolt is specifically designed for heavy equipment and can provide extremely high tensile and shear strengths. It is ideally suited for use in heavy load and high vibration environments. While the rivet is also very strong, it will not have the tensile and shear strength of the huck bolt.

3. Durability and Reliability

Both huckbolt and rivet are excellent for their durability and reliability. huckbolt can provide your application with high durability, vibration resistance and excellent dynamic load performance. It can effectively minimize the risk of loosening and dislodging. rivet, while also having high durability performance, may require more maintenance in high vibration environments.

4. Application Scenario

Huckbolt is often used in heavy equipment because of its extra strength. For example, heavy vehicles, railroad connections, steel construction of buildings, and high load structures such as mining equipment.Rivet is not as strong as huckbolt, but still provides a high level of strength.Rivet is used in a variety of industrial equipment. Rivet is used in a variety of industrial equipment, more often in construction, automobile manufacturing, electronic equipment connections, and so on.

5. Costs

Engineers who work with huckbolt and rivet on a regular basis should be well aware that the cost of huckbolt is much higher than rivet, and that more materials are used in its manufacture.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Which One Should I Choose?

The choice of riveted fasteners depends on your project. You need to determine your project’s specific requirements for characteristics such as strength and durability.Huckbolt can provide you with extreme strength and durability, but it is more costly. You can use it for applications that require ultra-high strength connections.

Rivet has a wider range of applications and can join a variety of materials. This includes plastics, brittle materials and composites. It also enables you to complete your projects quickly.

So, if your project involves heavy equipment or steel structures that require high strength, huckbolt is best suited for your project. However, if your project does not require that much strength, you should choose rivet.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

Huckbolt and rivet basically fulfill every application scenario. It allows you to equip your project with a secure and stable connection. These rivets also keep your project looking great, making it perfect for high-end projects.

However, you need to make sure that you choose the most appropriate joining technology for your project. Consider the differences to choose the riveting technology that best suits your specific needs. Create the future through stable connections with top-of-the-line huckbolt and rivet from top rivet manufacturer.

Get HuckBolt and Rivets for Your Projects From Rivmate

Riveting is an effective and accurate method of making connections. Huckbolts and rivets make this possible. the Rivmate rivet offers high quality huckbolts and rivets to meet your needs. You can also explore several other sheet fastening solutions at Rivmate rivet. Request a quote to get the best riveting solution for your project and start making secure connections.