Table of Contents

Learn 8 benefits of high strength structural blind rivets to shorten the process of ordering your structural blind rivets. Learn more now!

Table of Contents

Blind rivets have become the premier joining fastener for joining thin sheet materials for major manufacturers around the world. Few other fasteners can match the simplicity, speed and consistency of the connection. High-strength structural blind rivets have proven their superiority in a variety of industrial applications due to their consistent shear and pull-out strengths.

Read on to learn more about the many benefits of structural blind rivets.

What Are Structural Blind Rivets?

Structural Blind Rivets are blind rivets designed to withstand high strength and severe conditions. Unlike conventional blind rivets, structural blind rivets provide higher shear and pull-out forces and the mandrel is securely locked into the body of the rivet during the riveting process to form a monolithic structure.

Heavy equipment requires strong connections until the equipment stops due to failure. Therefore, high strength structural rivets are the preferred choice for connecting heavy duty applications.

Riveting is the formation of a stable mechanical connection by squeezing the rivet body. Riveted sheets are generally not very thick, from 3mm to 50mm can be connected using structural blind rivets. Therefore, for sheet metal blind fasteners, blind rivets can outperform almost any other joining method.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

8 Benefits of High Strength Structural Blind Rivets

Why do many projects choose to use the more expensive structural rivets? Because structural rivets have many advantages that blind rivets do not have.

1. Extremely High Strength and Reliability

High Strength Structural Rivets are capable of providing extremely high shear and pull-out forces. Structural Rivets maintain excellent stability and security in applications where high loads need to be applied. This is especially true in aerospace, automotive manufacturing and construction where high strength connections are required. High strength structural blind rivets are used very frequently.

2. Blind End Installation

The great advantage of Blind Rivets is that they can be installed from one side without the need to access the other side of the joint. Structural rivets also offer this advantage.

In many structures, access to the other side of the joint may be difficult or impossible. Blind rivets offer an easy installation solution, making them particularly suitable for use in confined spaces or complex structures. This is one of the reasons why blind rivets are becoming increasingly popular.

3. Anti-Vibration and Anti-Loosening

Unlike ordinary blind rivets, structural blind rivets have a mandrel that is locked into the rivet body. This special locking mechanism effectively prevents the mandrel from loosening or falling out, providing superior vibration resistance.

The vibration resistance of structural blind rivets is particularly important in high vibration or dynamic load environments such as aircraft, automotive and machinery. Excellent vibration resistance ensures that the connection remains strong over long periods of time without loosening or failing.

4. Quick and Easy Installation

Compared to other connecting fasteners, Blind Rivets and Structural Rivets require only a specialised rivet gun for quick installation. The entire process of installing structural blind rivets is very simple and fast.

Projects using structural rivets can reduce installation time and labour requirements by a significant amount. For manufacturers, this increases productivity and is ideal for engineers working on mass production and on-site construction. If your project has a very short production time, structural rivets are perfect for you.

5. Long Lasting Durability

Structural rivets are known to be strong. Due to their strength and corrosion resistance, structural rivets maintain a stable connection even under extreme conditions. For a qualified project, this feature reduces damage caused by environmental factors.

With proper installation, high strength structural rivets are virtually immune to damage or connection failure. You can reduce maintenance frequency and costs and extend the life of your structure, making it a cost-effective fastening solution.

6. Fatigue Resistance

Because of the unique structural design of the Blind Rivet, it effectively disperses stresses and reduces stress concentrations. If your project is in an environment that is subjected to dynamic loads for a long period of time, such as bridges and railways. High-strength structural rivets provide excellent fatigue resistance, the perfect solution to this problem.

7. Consistent Installation Quality

Structural Rivets are installed with excellent consistency. Structural Rivets provide a consistent tightening force and locking mechanism during installation. This ensures consistent quality at each joint, reducing the failure rate of joints and improving the safety of the entire structure.

8. Various Types Available

There are many different types of structural pop rivets in order to apply to different scenarios. These include the high-strength lockbolt rivets and bomb rivets, the waterproof bulb tite rivets, and the most popular monobolt rivets, and they are available in a wide range of materials including aluminum, steel, and stainless steel. these structural pop rivets are used for most applications.

If you would like to learn more about the types of structural pop rivets, check out this article.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Applications of Structural Blind Rivets

High-strength structural pop rivets can be applied to all forms of sheet metal products. Therefore, any task that could theoretically be accomplished with welds and bolts can be accomplished more quickly with structural pop rivets.

Below is a brief list of the most popular applications for structural pop rivets.

1. Aircraft Equipment and Structural Connections

Airplanes generate a lot of vibration due to being in motion for a long period of time. Therefore, fasteners used in airplanes need to have good vibration resistance. Structural blind rivets are well suited to this condition.

Almost every aerospace manufacturer purchases large quantities of high-strength structural rivets, which speeds up the process of building airplanes. Most structural blind rivets are used to attach critical structural components such as fuselages, wings and tails. In addition to this, structural rivets are used for equipment and panels inside the airplane, such as making an addition, instrument panels and baggage compartments. The core-pulling woolen empire ensures that these devices do not come loose during flight.

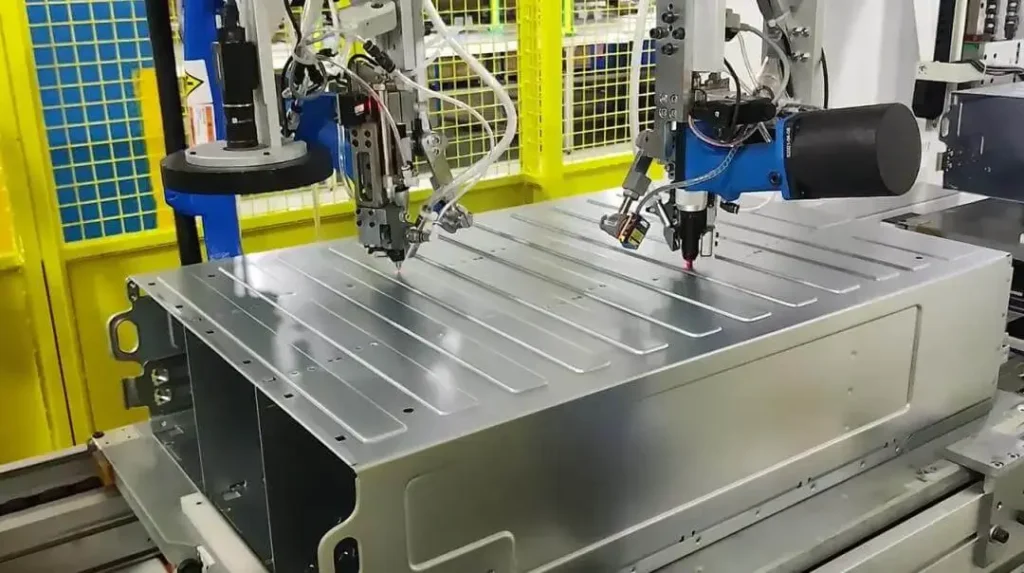

2. Installation of Automotive Components

The birth of a competent automobile is filled with a large number of connecting fasteners that work together to make a car. Structural blind rivets are one of these important components.

High strength blind rivets connect body panels, doors, hoods and chassis.

3. Building Facade and Structural Steel Connections

A lot of structural pop rivets are used in the construction field. Structural blind rivets can be used to connect steel beams, braces and other structural components during construction.

Structural blind rivets can also be used to secure curtain wall systems, metal panels and glass facades of buildings.

4. Shipbuilding

Ships will use a large number of solid rivets in addition to structural rivets to complete the deck connections.

There will also be a lot of equipment on the ship. These rivets would also have been used for ancient imperial radar mounts, life-saving equipment, and other vital components.

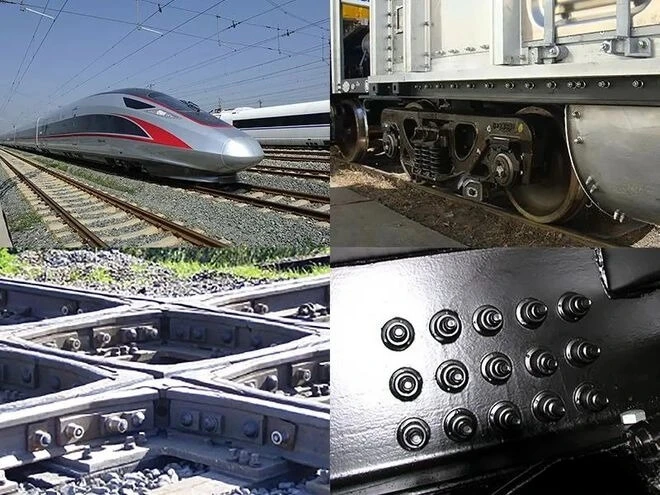

5. Railroad Tracks and Heavy Equipment

On a railroad, the track will use structural rivets for track fastening and attachment. Railroad vehicles also use a large number of high-strength structural rivets for the connection of the body structure, chassis and other load-bearing components.

6. Solar Energy System

With the popularity of the new energy concept, structural rivets are being used more and more. Many solar providers use structural rivets to secure solar panels to keep them working stably in long-term outdoor environmental exposure.

When Jean, in some large solar projects, the tracking brackets for solar panels are held in place using a large number of structural rivets.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Conclusion

High strength structural rivets can be used in a variety of application scenarios. Increased use of structural blind rivets can provide overall productivity and reduce production time. Structural Rivets can join a wide range of materials. Blind rivets do not require repetitive inspections and repairs, which saves on labor costs and risk.

Buy Structural Blind Rivets from Rivmate!

Rivmate is the top pop rivet manufacturer. with years of expertise and a commitment to providing quality service to our customers, we have served over one hundred countries and territories for over a decade.

We are confident that our wide range types of structural pop rivets will fulfill your riveting needs. Get a quote today!