9 vs 12 copper rivets: Size, Application and Selection Guide

Table of Contents

In traditional craftsmanship and structural reinforcement applications, copper rivets possess excellent ductility, corrosion resistance and retro aesthetic appeal. It is widely used in leather products, horse gear making, wooden ship restoration and various light structure assembly scenarios. In these practical applications, the selection of rivet sizes is of vital importance. Especially the two common models, #9 and #12, often appear in the selection lists of manufacturers and engineers. The “numbers” of copper rivets, such as #9 and #12, actually represent their diameter dimensions. It directly affects its load-bearing capacity, the thickness of applicable materials and the appearance of the finished product. Understanding the differences between 9 vs 12 copper rivets is essential for ensuring structural integrity, aesthetic balance, and installation efficiency.

This article provides a clear comparison of #9 and #12 copper rivets in terms of size, applications, and how to make the right choice for your specific project.

What Do Rivet Size Numbers Like #9 and #12 Really Mean?

When selecting copper rivets, understanding what the “#” size system represents is crucial to ensuring both structural integrity and compatibility with your application. Rivet size numbers like #9 and #12 follow standardized specifications based on shank diameter. This numbering system is clearly defined in industry standards such as those from the Industrial Fasteners Institute (IFI), the American Society of Mechanical Engineers (ASME), and commonly accepted leathercraft guidelines.

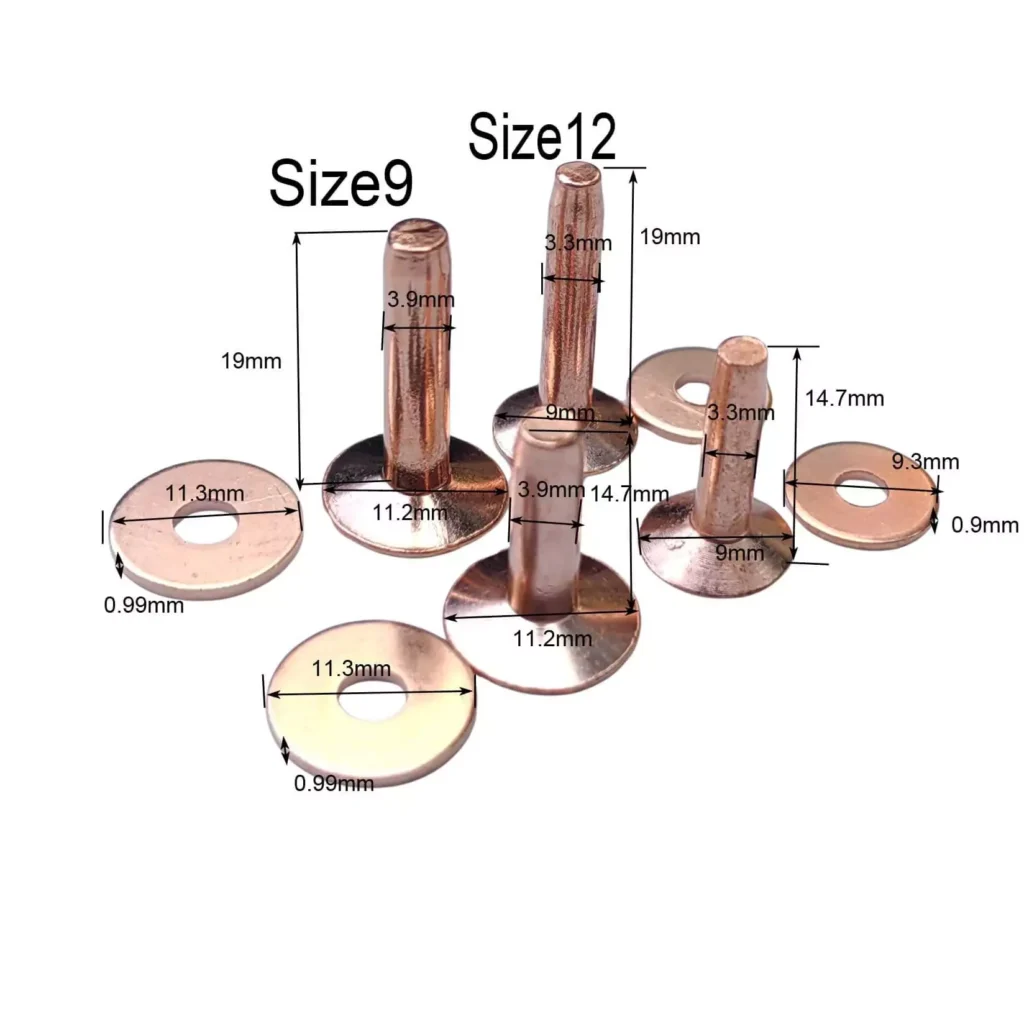

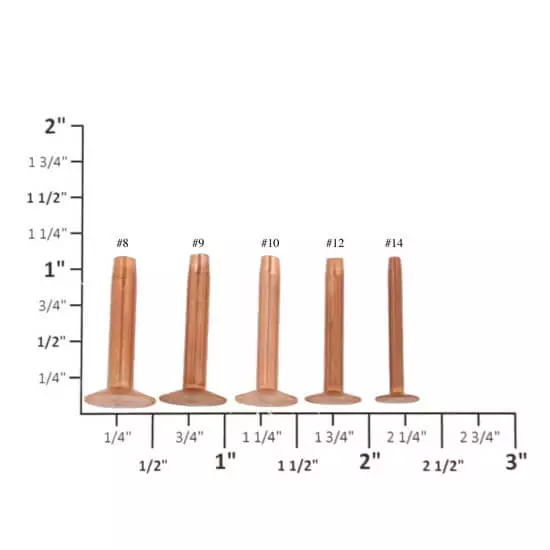

Apart from the diameter of the rod, the complete dimensions of the copper rivet also include the diameter of the head (Head Diameter) and the overall length (Overall Length). These three factors jointly determine the bearing capacity and applicable scenarios of the rivet. Here is a simple table showing the relationship between common rivet sizes and their dimensions:

Rivet Size (#) | Shank Diameter (inches) | Head Diameter (approx.) | Common Applications |

#9 | 0.144 in | ~0.312 in | Leatherwork, woodworking, light structures |

#12 | 0.180 in | ~0.375 in | Boat hull repair, heavy-duty assemblies |

How Do 9 and 12 Copper Rivets Compare in Size and Strength?

When choosing copper rivets, the two common types, 9 copper rivets and 12 copper rivets, have significant differences in terms of size and performance. It can directly affect the load-bearing capacity and applicability of the riveted structure. The following are the key points for comparison:

1. Shank Diameter

The rod diameter of #12 copper rivets is approximately 1/4″ (≈ 6.4 mm), which is significantly thicker compared to #9’s 3/16″ (≈ 4.8 mm). This size difference not only enhances the tensile and shear resistance but also provides a more stable assembly and fastening effect. It is particularly advantageous in scenarios with frequent loading or high loads.

2. Rivet Head Diameter

The diameter of the head determines the pressure distribution between the rivet and the connected material. The size range of #12 heads is typically 7/16″ – 1/2″ (≈ 11 – 13 mm), significantly larger than that of #9, which is 3/8″ (≈ 9.5 mm). A larger head helps reduce indentation and prevent material deformation, making it suitable for soft or thin materials。Especially in situations where appearance and structural integrity are important.

3. Length Range

#12 copper rivets typically have lengths ranging from 1/4″ to 1″, covering a wider range of thickness combinations for fastening requirements. While #9 has a standard length usually ending at 3/4″. For multi-layer materials or structural components that require deeper penetration, #12 offers greater flexibility and engineering margin.

4. Tensile/Shear Strength

In terms of structural strength, since #12 has a larger cross-sectional area, it performs significantly better than #9 under tensile and shear loads. In practical applications, #12 is more suitable for areas that need to withstand dynamic loads, vibrations, or concentrated structural stresses. The use of #9 is usually more focused on size compactness or aesthetics rather than ultimate strength.

5. Application Suitability

- #9 Copper Rivets: Often used for lightweight applications, such as leather goods crafting, furniture decoration, thin wood board connections, etc. They are characterized by ease of operation and exquisite appearance.

- #12 Copper Rivets: Widely used in medium-load structural connections, such as ship repair, industrial sheet metal work, wooden decks, mechanical guards, etc. They emphasize their durability and load-bearing capacity.

Size and Performance Comparison Table: 9 vs 12 Copper Rivets

Parameter | #9 Copper Rivet | #12 Copper Rivet |

Shank Diameter | ≈ 3/16″ (approx. 4.8 mm) | ≈ 1/4″ (approx. 6.4 mm) |

Head Diameter | ≈ 3/8″ (approx. 9.5 mm) | ≈ 7/16″–1/2″ (approx. 11–13 mm) |

Available Length Range | 1/4″ – 3/4″ | 1/4″ – 1″ |

Material | Solid Copper | Solid Copper |

Tensile/Shear Strength | Moderate | Higher |

Typical Applications | Leatherwork, light woodworking, decorative joints | Boat hulls, structural repair, industrial use |

Where Are Different Sizes of Copper Rivets Most Commonly Used?

Typical Application Scenarios of 9 Copper Rivets (Preferred for Lightweight Connections)

- Leather Goods Manufacturing: 9-gauge copper rivets are widely used in leather goods. They are suitable for connecting components such as belts, horse tack, wallets, key cases, and vintage backpacks. Their compact size provides the necessary holding force without affecting the appearance of the finished product. They are typically used for localized reinforcement of non-load-bearing components, combining both decorative and functional purposes.

- Thin Wood Panel Joining: In light wood structures such as furniture manufacturing, decorative crafts, and model construction, #9 copper rivets enable quick, high-density connections. Since they cause minimal deformation after riveting and are unlikely to split wood, they are often used for local connections in panels, decorative strips, or edging.

- Lightweight mechanical assembly: This includes the connection and fixation of structures such as electrical enclosures, thin sheet covers, and small hardware brackets. While the shear strength of #9 rivets is limited, it is sufficient to meet the fixation requirements of non-structural components. Their copper material has excellent conductivity, enabling multifunctional integrated assembly in certain grounding or conductive structures.

Typical Application Scenarios of 12 Copper Rivets (For Medium Load Structural Reinforcement)

- Thick leather or composite material fastening: 12 copper rivets can penetrate multiple layers of material without riveting failure. Due to their stronger clamping force, they prevent loosening or misalignment between materials, enhancing connection lifespan and safety.

- Medium to heavy-duty wood structure repair: 12 copper rivets serve as ideal medium-load stress reinforcement fasteners. They are often used with copper washers to improve load distribution and corrosion resistance.

- Shipbuilding and equipment maintenance: In high-strength environments such as wooden ship hulls and steel-wood hybrid structures, #12 copper rivets offer high shear strength and corrosion resistance. Copper exhibits excellent adaptability to seawater and humid environments, meeting the demands of long-term fatigue resistance and stability in such conditions.

How Do You Choose the Right Copper Rivet Size?

a. Select the Shank Diameter Based on Material Thickness

When choosing copper rivets, the rivet grip range is one of the most critical parameters for ensuring a secure and reliable connection. The grip range refers to the total material thickness that a rivet can effectively clamp during proper installation, typically measured in millimeters or inches.

How to Calculate Rivet Grip Range:

Grip Range = Total thickness of all materials being joined (including any spacers or inner layers)

Example:

- If you’re fastening two layers of leather (2 mm and 1.5 mm thick) along with a copper washer (0.5 mm), the total thickness is 4 mm, so you should choose a rivet with a 3–5 mm grip range.

How to Match Grip Range with Shank Diameter:

Grip Thickness Range | Recommended Rivet Size | Description |

2–4 mm | #9 | For fine connections such as light-duty leather or thin sheet joints |

3–5 mm | #9 (preferred) | Ensures enough deformation without loosening |

5–7 mm | #12 (recommended) | Provides stronger clamping force for thicker, layered materials |

7–10 mm | #12 (optimal) | Prevents under-clinching and ensures proper shear strength |

Note: When the material thickness approaches the upper limit of the grip range, it’s best to choose a slightly longer rivet to avoid insufficient clamping and potential loosening.

Why Shank Diameter Affects Clamping Stability:

- Smaller shank diameters (e.g., #9)deform more easily during riveting, making them suitable for light-duty assemblies.

- Larger shank diameters (e.g., #12)deliver greater clamping force and resistance to deformation, especially ideal for harder materials, composite stacks, or load-bearing areas.

For instance, in an assembly involving wood + metal + leather with a total thickness of 6 mm, using a #12 copper rivet helps prevent slipping or noise caused by insufficient grip.

b. Pre-Drilled Hole Size Matching

To prevent rivet loosening or material cracking during assembly, it’s essential to use drill bits that precisely match the rivet size:

Rivet Size | Recommended Drill Bit | Tolerance Suggestion |

#9 | 3/16″ (≈ 4.76 mm) | +0.1 ~ +0.2 mm |

#12 | 1/4″ (≈ 6.35 mm) | +0.1 ~ +0.2 mm |

A hole that’s too small may make rivet insertion difficult, while a hole that’s too large can compromise joint stability.

c. Tool Compatibility Requirements

Larger rivets such as #12 require more robust tools during installation, including larger dies, manual clamps, hydraulic riveters, or specialized jigs. Using standard tools for #12 rivets may result in incomplete deformation, affecting the overall strength of the connection. Therefore, we recommend:

- #9: Can be installed using hand tools or lightweight rivet setters;

- #12: Best installed using dedicated dies (die diameter 6.4–6.6 mm) and tools with adequate clamping force.

d. Structural Strength Requirements

If the joint will be subjected to significant shear force, tensile load, or long-term vibration, #12 copper rivets should be prioritized. Their larger cross-sectional area and wider head provide superior mechanical strength and fatigue resistance compared to #9 rivets.

Use #12 rivets especially in the following scenarios:

- Equipment mounting surfaces

- Mixed-material assemblies (e.g., metal + wood)

- Load-bearing or high-vibration areas

- Humid or corrosive environments

What Tools Are Needed for Copper Rivet Installation?

Installing copper rivets involves more than just the rivets themselves—choosing the right accessories and tools is key to ensuring clamping force, aesthetic quality, and connection reliability. Especially in industrial assembly or precision leathercraft, the compatibility between rivets and copper burrs, as well as proper tool selection, directly affects the final product’s performance.

①. Burr Compatibility

Copper burrs, also known as rivet washers or caps, are placed on the rivet’s tail end and serve three main purposes:

- Enhance clamping force:Increase the bearing surface to improve rivet stability;

- Prevent material tearing:Protect the joint surface from damage caused by rivet deformation;

- Aesthetic and symmetry:Provide a neat appearance, especially important for exposed surfaces requiring uniformity.

Compatibility:

- #9 rivets requireburrs sized for 3/16″ holes;

- #12 rivets requireburrs sized for 1/4″ holes;

- Burrs for these two sizes are not interchangeable, as using the wrong size may lead to insufficient clamping or installation failure.

②. Installation Tools and Die Selection

Rivet setting generally involves three basic tools: the setter (mandrel), anvil, and die/rivet tool system. Recommended selection guidelines are as follows:

Item | #9 Rivets | #12 Rivets |

Manual Riveter | Small handheld riveter (light-duty) | Medium to large riveter or bench clamp system |

Setter Diameter | Tail groove diameter ≈ 4.8 mm | Tail groove diameter ≈ 6.4 mm |

Anvil Design | Matching groove to fit burr outer diameter | Larger groove with guiding effect |

Hydraulic/Pneumatic Tools | Optional, suitable for batch work | Recommended to ensure consistency |

If high consistency and efficiency are required, especially in production lines or heavy-duty connector operations. It is recommended to use a dedicated riveting tool head (with replaceable die) in conjunction with the hydraulic system. To ensure that the clamping depth and deformation of each rivet are uniform and consistent.

FAQs

1.Can 9 and 12 Copper Rivets Be Interchanged?

9 and 12 copper rivets differ significantly in shank diameter, head diameter, and clamping force. And requiring different drill hole sizes, burr specifications, and installation tools. Misuse may lead to:

- Loose or off-center riveting;

- Material cracking or insufficient clamping;

- Inconsistent appearance or stress concentration in the structure.

2. Which Rivet Should Be Chosen for Different Material Thicknesses?

The decision should primarily be based on the grip range:

- Material thickness ≤ 5 mm → recommended #9 copper rivet;

- Material thickness > 5 mm → recommended #12 copper rivet;

- For multi-layered or load-bearing structures → prefer #12 with matching copper burrs.

3. Are Copper Rivets Suitable for Electrical Grounding Applications?

Yes, and they offer advantages.

Copper inherently provides excellent electrical conductivity and corrosion resistance, making it ideal for grounding, anti-static, or shielding applications such as:

- Electrostatic grounding clamps;

- Connections between copper strips/bars and enclosures;

- EMI shield mounting points.

4. Copper Rivets vs. Aluminum Rivets: Impact on Structural Strength

Comparison | Copper Rivets | Aluminum Rivets |

Strength Performance | Higher shear and tensile strength | Moderate strength, lightweight |

Corrosion Resistance | Excellent (especially in humid/marine environments) | Good, but prone to pitting corrosion |

Ductility | High, suitable for forming | Moderate, prone to cracking |

Electrical Conductivity | Excellent, ideal for grounding | Average, not preferred for conductive joints |

Recommended Uses | Medium-load structures, electrical connections, corrosion-resistant applications | Light-load joints, weight-sensitive products |

In summary, when structural strength, electrical performance, or harsh environments are critical, copper rivets offer superior safety and durability.

Choose Rivmate Copper Rivets

Whether you are engaged in leather crafting, woodworking assembly, or repairing traditional ship structures, choosing the right size of copper rivets is of utmost importance. Rivmate offers a full range of #9 and #12 copper rivets, strictly adhering to international standards to ensure precise dimensions and stable performance. Our rivets are made of high-purity solid copper and possess excellent corrosion resistance and structural strength. They are suitable for various handicraft and engineering applications.

Buy Rivmate copper rivets immediately to create stronger, more attractive and more reliable connections for your project!

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met