Table of Contents

Before buying Sealed Rivets, you must need to know about Sealed Rivets. This blog tells you everything you need to know about sealed rivets and can help you to be well prepared before you officially buy sealed rivets.

Table of Contents

What is a Sealed Rivet?

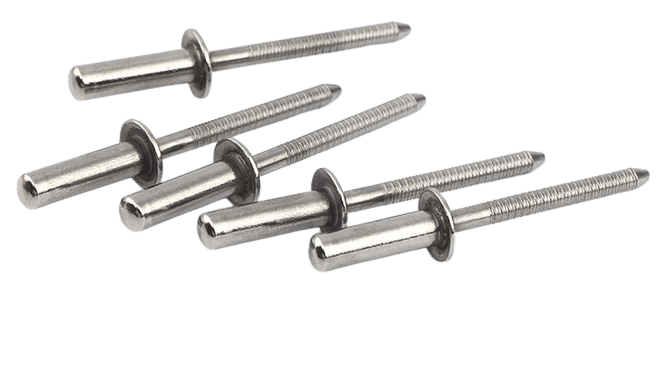

Sealed Rivets, also known as Closed End Rivets, are mechanical fasteners. Unlike traditional blind rivets, it is designed to provide a high-strength connection while ensuring a tight seal at the joint. Closed end rivets have a completely closed end, a design that effectively prevents the ingress or leakage of liquids, gases or other substances through the rivet body.

While the history of rivets goes back thousands of years, closed rivets were developed in the mid-20th century. Because of the unique design of the closed rivet, it was first used in applications that required high sealing performance, such as aerospace and automotive manufacturing.

How do Sealed Rivets Work?

Sealed Rivets work similarly to other types of blind rivets, but are unique in that they have a closed tail design that provides sealing performance.

Like open end blind rivets, sealed rivets form a stable connection by extruding and deforming the rivet body. The difference is that with a closed rivet, the tail of the rivet body expands outward under the action of the mandrel head, creating a blind head which holds the material securely between the rivet head and the blind head.

And the closed design of the Sealed Rivet ensures that the tail is completely enclosed, preventing liquids or gases from entering or escaping through the rivet.

How Do You Install Closed End Rivets?

1. Preparatory work

- Drilling: Drill holes matching the rivet diameter in the material to be joined. The size and location of the holes must be accurate to ensure proper insertion of the rivets.

- Insert the rivet: Insert the rivet body of the sealing rivet into the pre-drilled hole with the head of the rivet against the surface of the material and the mandrel protruding from the opposite side of the material.

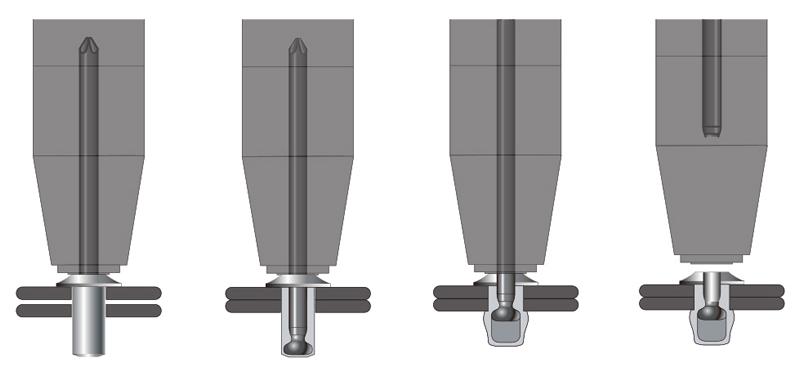

2. Pull the mandrel

- Start the rivet gun and pull the mandrel. The head of the mandrel pulls the bottom of the rivet body outward and expands during the pulling process, thus securing the material.

3. Forming the hold and seal

- Rivet Body Expansion: Under the action of the mandrel head, the end of the rivet body expands outward to form a “blind head”. The blind head holds the material securely between the rivet head and the blind head.

- Mandrel Break: Once the rivet body is fully expanded and the material is secured, continue to pull on the mandrel until it breaks at the preset break point. After the mandrel breaks, the remaining portion remains in the rivet body, completing the seal and securing.

4. Inspection and acceptance

- Ensure that the rivets are securely installed and not loose. Check that the rivet head and blind head fit tightly to the surface of the material to ensure the sealing of the joint.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

What Are Sealed Pop Rivets Used For?

Sealed rivets, one of the most commonly used blind rivets, provide excellent sealing performance in addition to strong joint strength. They can effectively prevent the penetration or leakage of liquids and gases, and provide corrosion protection in harsh environments.

Aerospace

Sealed rivets will be used in the connection of structural components such as aircraft fuselage and wings. It is mainly used to seal joints to prevent air and liquid infiltration, ensuring airtightness and structural integrity in the cabin.

Automotive Manufacturing

Closed rivets are used in the attachment of components such as automobile bodies, chassis and fuel tanks. This includes use in areas such as fuel tanks that need to be sealed to prevent fuel leakage.

Construction and Infrastructure

Metal panels on roofs, facades and building exteriors need to be waterproof. Therefore, sealed rivets are used to connect and seal the metal panels on the exterior of the building to prevent rain and moisture from entering the interior of the building to improve the durability and waterproofness of the structure.

Piping Systems

Closed end pop rivets are used extensively in piping connections. It provides a tight seal to prevent leakage of liquids and gases, especially when handling hazardous chemicals or high-pressure fluids.

Public Infrastructure

Traffic signs, guardrails and signals that are exposed to the outdoors for long periods of time, sealed rivets provide reliable fastening and waterproofing, extending the life of the equipment.

Pros and Cons of Sealed Rivets

Even though closed end pop rivets are very popular, they still have their own advantages and disadvantages. Of course, if you want to learn about the advantages and disadvantages of pop rivets, you can read the hyperlinked

Pros of Sealed Pop Rivets

- The closed tail design of the sealing rivet effectively prevents liquids, gases and other substances from penetrating through the rivet hole, providing an excellent seal.

- Due to its closed design, the internal and external structure of sealed rivets can effectively resist corrosion, especially in wet or corrosive environments.

- Sealed rivets can provide strong tensile and shear strength to ensure the stability and safety of the connection.

- After the sealed rivets are installed, the closed end does not leave exposed mandrel remnants for a neat appearance.

- The closed design avoids exposed mandrel remnants and reduces the risk of potential injury to other equipment or personnel.

Cons of Sealed Pop Rivets

- Sealed rivets typically cost more than open end rivets due to their complex manufacturing process and the high performance materials used.

- Once installed, sealed rivets form a permanent joint that is difficult to remove, often requiring destructive means such as drilling or cutting.

- Sealed rivets are primarily suited for metal-to-metal connections and are not well suited for soft materials such as wood or plastic.

What Are the Rivets that Don't Leak?

Rivets that do not leak are generally defined as rivets that are designed to provide an effective seal that prevents liquids from leaking through the joint. Such rivets are typically used in applications that require a watertight, airtight seal. Below are a few common types of watertight rivets:

Before choosing the rivets that will not leak, you should consider the following points clearly:

- Application environment: choose the right type of waterproof rivets according to the application environment, for example, you need to consider whether it is exposed to water, chemicals or other corrosive media.

- Material compatibility: Ensure that the rivet material is compatible with the material being joined to avoid galvanic corrosion or material degradation.

- Sealing Requirements: Select rivets based on the sealing requirements of the application scenario, such as whether they need to be completely waterproof, airtight etc.

In short, rivets that do not leak, such as closed rivets and waterproof bulb tite rivets, are designed to prevent the penetration of liquids or gases. Choosing the right type of rivet can effectively ensure the sealing and safety of the connection and meet the waterproof and gasproof needs in different environments.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How Do You Stop Rivets from Leaking?

Want to be your project to achieve good waterproofing. There are several measures that generally need to be taken:

- Selection of rivets with sealing structure

- Use of sealant

- With rubber gasket

Frequently Asked Questions About Sealed Rivets

In order to solve your questions about closed rivets more quickly, I have listed a few common questions for your reference.

Are Sealed Rivets Permanent?

Closed End Rivets are often designed as permanent connections, which means they are not easily removed or readjusted once installation is complete.

Closed end rivets have a completely enclosed tail. This design not only provides a watertight and airtight seal, but also makes the rivet difficult to remove from the joint after installation. During installation, the mandrel of the rivet expands the rivet body by tension, creating a tight locking structure.

The installation process of a closed rivet consists of inserting the rivet into a pre-drilled hole and then pulling the mandrel through the rivet gun to deform the rivet body and secure it to the material. This process causes the tail of the rivet to expand and press against the inside of the material, creating a strong mechanical joint. Because this deformation is irreversible, the rivet is essentially impossible to remove after installation without damaging the joining material or the rivet itself.

Once installed, the removal of a closed rivet usually requires the use of specialized tools, such as a drilling machine to drill out or cut off the rivet. This operation usually damages the rivet and the surrounding material, so closed rivets are not suitable for connections that require frequent disassembly or adjustment.

Why Use a Rivet Over a Screw?

The choice to use rivets rather than screws depends on a variety of factors, including the strength requirements of the connection, the installation environment, the type of material, and the cost. Here are some of the main reasons for using rivets rather than screws:

- Rivets typically provide a permanent mechanical connection that, once installed, is difficult to remove.

- When joining materials, rivets are able to distribute stresses evenly across the joint, reducing stress concentrations.

- Rivets will not loosen due to vibration or stress.

- Compared to screws, blind rivets (e.g., open end blind rivets and closed end rivets) allow for unilateral operation, making it easy to install from only one side.

- Installation with rivets is often more efficient in mass production, especially in automated production lines. The cost of rivets is generally lower than screws, especially when speed of installation and tooling costs are considered.

If you’re interested in the difference between rivets and screws, you can read this post of mine.

Order High Quality Sealed Rivets from Rivmate

Rivmate as a top manufacturer and supplier of rivets in China. We can provide you with various types and materials of closed rivets. Including the following head types:

- Dome Head

- Countersunk Head

- Large Flange Head

Different Material Combinations:

- Aluminum Rivet/Steel Mandrel

- Aluminum Rivet/Aluminum Mandrel

- Aluminum Rivet/Stainless Steel Mandrel

- Steel Rivet/Steel Mandrel

- Stainless Steel 304 Rivet/Stainless Steel 420 Mandrel

- Stainless Steel 304 Rivet/Stainless Steel 316 Mandrel

- Copper Rivet/Steel Mandrel

If you have any purchasing needs and questions about Closed Rivet, please contact our engineers. He will give you a perfect solution for Closed Rivet.