Table of Contents

As plastics become more and more popular, rivets are increasingly used in plastics. The use of pop rivets on plastic requires special consideration for optimum performance. You must choose the right type of rivet and material to achieve a long-lasting connection.

Plastic can be softer or more brittle than other materials. Therefore, it is important to choose a blind rivet that will provide a strong connection without damaging the plastic material. To solve this problem, grooved blind rivets are an excellent choice.

Table of Contents

What is a Grooved Blind Rivets?

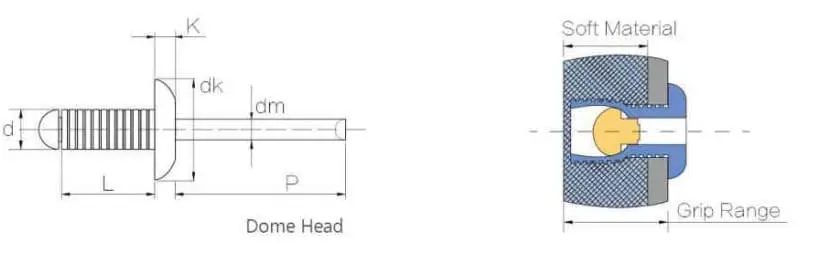

Grooved pop rivets are a type of blind rivet. Its basic design and working principle is the same as other types of pop rivets.The difference between Grooved pop rivets is that the joints are fixed in a different way.

Although the installation is the same, grooved blind rivets come with grooves in the rivet body. This groove can be embedded in the connecting plastic during installation to provide additional mechanical grip and retention.

The unique grooved rivet design makes it an excellent choice for joining plastic materials. As long as the size of the rivet you use matches the diameter of the hole, it will create a strong fastening in the plastic.

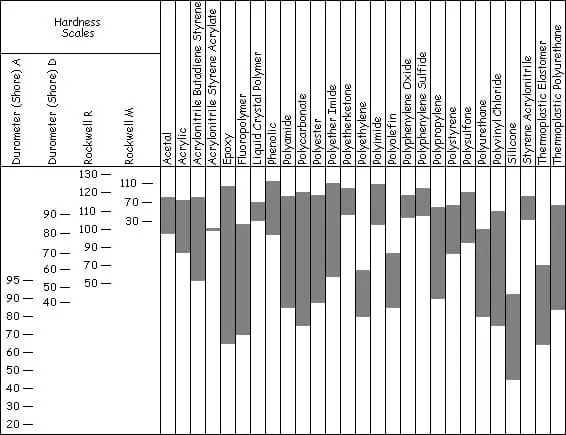

Strength of Plastics

Plastic, one of the most commonly used materials, is very hard. It is nowhere near as hard as other commonly used materials. The image above demonstrates the strength index of plastic.

Since the strength of plastic is so low and it is used so often, it becomes a problem to connect the plastic components.Grooved pop rivets were created to solve this problem.

Why Use Grooved Blind Rivets to Join Plastics?

The low strength of plastic makes joining it a problem, and Grooved pop rivets offer an excellent solution.Grooved pop rivets offer a number of advantages not found in other blind rivets, making them ideal for joining plastic products. Here are some of the main reasons why grooved pop rivets are great for joining plastic products:

1. Enhanced Grip

The unique design of the Grooved Blind Rivet features a series of grooves on the surface of the rivet body. These grooves are able to embed themselves in the plastic material during installation, increasing friction and therefore grip. This feature is especially important in softer or more brittle plastics as it prevents the rivet from slipping or loosening under stress.

2. Even Stress Distribution

The groove design helps to spread the stress over a larger area, thus reducing the stress concentration and lowering the risk of material rupture. Plastic materials are relatively fragile and susceptible to damage due to stress concentrations, so grooved blind rivets can better protect the material.

3. Aesthetic Effects

Not only do grooved blind rivets provide a strong mechanical connection, they can also be used to achieve a good integration with the product design by choosing different head styles and colors. Special designs such as large flange heads can provide better decorative effects while increasing the contact area to further enhance the stability of the connection.

4. Efficient Cost Control

Due to the low material cost of grooved blind rivets, simple manufacturing process, and fast installation, the use of them can effectively control production costs, especially in high-volume production. Compared with other fastening methods, the economy and efficiency of grooved blind rivets is more prominent.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Choose the Right Grooved Blind Rivets for Plastic?

When choosing the right rivet for riveting plastic materials, you need to find a blind rivet that improves the tight connection without damaging the material.

Here are some things to consider when choosing the right grooved blind rivets for plastic or any soft material:

Geooved Rivets Diameter

When you use grooved pop rivets to join plastic items, the first step should be to determine the diameter of the rivets.

So how do you confirm the diameter of grooved pop rivets? You need to determine the total thickness of the plastic material being joined and the length of the rivets should accommodate the total thickness of the material. The diameter of the rivet needs to match the diameter of the hole. You need to make sure that the connection is stable and that the plastic does not break back.

Grooved Rivets Material

Once the rivet diameter has been determined, you need to consider which material to use for the rivets. The minimum requirement is that the rivet be made of a material that is harder than plastic. Most grooved pop rivets have a body made of aluminum or steel that is a lot harder than plastic. In addition, you need to consider the environment in which it will be used. For example, if you are using it in a marine application, do you need to choose a material that is resistant to corrosion.

Grip Range of Grooved Rivets

Grip range is the thickness of the material to which grooved pop rivets can be riveted.Grip range should match the thickness of the plastic material being joined.

If the grip range is too long, the rivets will be too long to get a neat finish. If the grip range is too short, there is no way to make a good connection. For example, if the total thickness of the plastic is 3.5mm, the grip range of grooved pop rives should be between 3-5mm.

In Addition to Plastic,What are Grooved Rivets Used for?

Grooved pop rivets are good for joining plastic materials in addition to a wide range of other soft or brittle materials. These include the following common materials:

- lumber

- Composites

- Rubber & Elastomers

- Textiles & Composite Structures

- Foam

- Soft metal alloys

Grooved pop rivets are installed in the same steps on these materials as they are on plastic. It is worth noting that when you use grooved pop rivets in your building, make sure they are made of corrosion-resistant materials.

Conclusion

Grooved pop rivets unique groove design works well for joining soft or brittle materials. Plastic materials are no exception. If your project requires joining materials that are not metal or are very thin, grooved pop rivets are an excellent choice.

Whether it’s plastics, composites, wood and fiber materials, grooved pop rivets do a great job of joining!

Order a Variety of Grooved Blind Rivets from Rivmate

If you want to order a large quantity of grooved pop rivets, Rivmate has the solution for you. We can offer grooved blind rivets in 1/8″, 5/32″ and 3/16″ sizes.

Contact us today for a quote on grooved pop rivets!