Table of Contents

In modern sheet metal assembly, manufacturing, and engineering maintenance, the rivet gun is a core tool for achieving efficient and stable riveting. However, during daily use, rivet guns often experience various malfunctions due to equipment aging, improper parameter settings, or non-standard operating procedures. Examples include incomplete core extraction, abnormal core breakage, insufficient air pressure, and riveting strength failing to meet standards.

These seemingly minor issues, if not promptly identified and addressed, can directly lead to product rework, structural failure, or even on-site shutdowns. This article systematically categorizes the 10 most common types of rivet gun failures, analyzes their causes through real-world case studies, and provides corresponding professional solutions and preventive recommendations. This blog can help engineers, assemblers, and maintenance personnel quickly pinpoint issues, reduce assembly defect rates, and ensure production efficiency and structural quality.

Table of Contents

10 Rivet Gun Problems and How to Solve

There are a variety of problems you may encounter when using a rivet gun. These problems can be very disturbing and affect work efficiency. Below I have listed some of the major common rivet gun problems and I have provided solutions.

1.Rivet Gun Jammed

I’m sure anyone who has used a rivet gun for any length of time has encountered this problem. So what is the reason for the rivet gun jamming? Below I have listed all the possible reasons.

- Rivet size is not suitable

- Clogged nozzle or worn jaws

- Rivet not properly placed in the gun nozzle

- Worn or damaged jaws, springs or other mechanical parts inside the rivet gun

- Lack of lubrication inside the rivet gun

- The air pressure of the pneumatic rivet gun is too low to produce enough force to pull the rivets.

How to Solve?

In response to the above problems, we need to target the problem. Here are some common solutions.

- Check the rivet size: use the rivet size that matches the rivet gun

- Clean the nozzle and jaws: Clean the nozzle and jaws of the rivet gun regularly.

- Ensure rivets are installed correctly: Make sure rivets are fully inserted and aligned in the holes

- Inspect and replace internal parts: If the internal mechanical parts of the rivet gun are worn, inspect and replace damaged or worn parts.

- Lubricate the rivet gun: Add the proper amount of lubricant to the rivet gun on a regular basis.

- Check air pressure (for pneumatic rivet guns): Make sure the air pressure of the pneumatic rivet gun is within the correct range.

2. Rivet does not tighten properly

If you are riveting a rivet and have a problem with the rivet not being fully tensioned or the rivet head breaking prematurely. Then it may be caused by the following reasons.

- Incorrect rivet size

- Insufficient tension in the rivet gun

- Defective rivets

How to Solve?

To solve this problem is actually quite simple. You need to check that the rivet size and rivet type is correct before riveting. And make sure that the tension of the rivet gun is within the qualified range. If the rivet itself is defective, just replace it.

3. Premature or Uneven Mandrel Breakage

If you are experiencing this problem while riveting rivets, then you can look for the cause in the following areas:

- The pulling force of the rivet gun exceeds the capacity of the rivet mandrel, resulting in premature breakage of the mandrel.

- Poor rivet material or defective manufacturing process of the mandrel (e.g., cracks or roughness on the surface of the mandrel).

- Rivets are used on materials that are too hard, causing the core bar to break prematurely due to excessive resistance during the riveting process.

How to Solve?

To solve this problem, you need to make sure that the tension of the rivet gun is within the tolerance of the rivet. Secondly, you need to use rivets that do not have quality issues so that you can ensure a good riveting result.

4. Premature Release of Mandrel from Rivet Gun

The problem of the rivet gun releasing the mandrel before the rivet is fully tensioned, resulting in the rivet not being set properly, can be caused by a number of factors. Below are common causes and their solutions:

- The jaws of the rivet gun are worn or damaged, preventing a firm grip on the mandrel.

- Insufficient tension provided by the rivet gun (especially pneumatic or electric models).

- The trigger or internal spring of the rivet gun is faulty.

How to Solve?

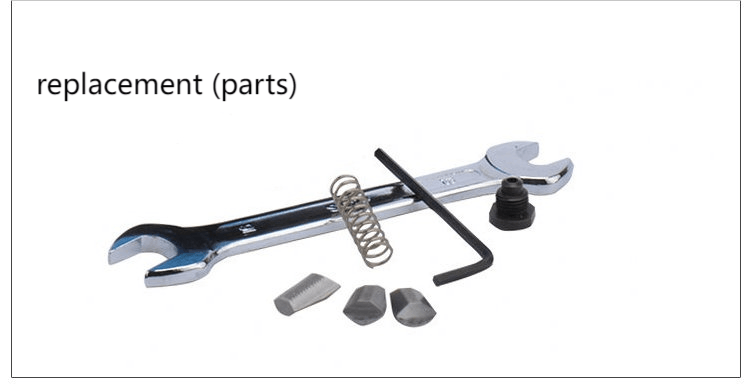

- Check and replace the jaws: check the jaws of the rivet gun for wear or damage, replace the worn jaws in time

- Adjust the tension setting: For electric or pneumatic rivet guns, make sure the tension setting is appropriate and not too low.

- Check the trigger mechanism and spring of the rivet gun: Check the trigger and internal spring of the rivet gun to make sure it can release the mandrel at the right time.

5. Jaw Slippage

Slipping jaws on the rivet gun and not being able to grip the mandrel properly is a common problem that usually results in the rivet not being pulled tight or failing to rivet smoothly. Below are the common causes and solutions that lead to this problem:

- Worn or damaged jaws

- Debris or crumbs in the jaws.

- Jaw spring failure or insufficient elasticity

- Use of improperly sized rivets

- Insufficient lubrication inside the rivet gun

- Jaws not aligned or improperly installed

How to Solve?

In fact, there are two main solutions to rivet gun jaw problems:

- Regularly clean the jaws and replace worn parts.

- Use the right size rivets.

6. Pneumatic Rivet Gun Leakage

When using a pneumatic rivet gun, gas leakage involves several main components: seals, air tubing and air pressure.

- Deteriorated or damaged o-rings or seals

- Loose or broken air tubing or fittings.

- Air compressor air pressure is unstable

How to Solve?

- Periodically inspect and replace o-rings or seals

- Ensure that the air hose and air coupling between the rivet gun and compressor are firmly connected.

- Adjust compressor air pressure to the proper range

- Ensure that the threads at the air inlet and fittings are securely installed.

7. Not Enough Pull

When you are riveting a rivet, the rivet gun may not be able to generate enough tension to pull the rivet.

Pneumatic rivet guns may be due to insufficient air pressure. An electric rivet gun may have a low battery.

How to Solve?

If you experience similar problems, check the air pressure of the pneumatic rivet gun and adjust it. Or charge or replace the battery of the electric rivet gun.

8. Trigger Not Responding

The trigger on the rivet gun is not pneumatic or is not responding. There are only two reasons for this problem: the trigger mechanism is faulty or there is a foreign object blocking it internally.

How to Solve?

How can we solve this problem? It usually requires the operator to clean the departure mechanism and check for damage or misaligned parts. Repair or replace faulty parts if necessary.

9.Rivet Feed is not Smooth

Rivet feed is not smooth when using a pneumatic rivet gun. Actually just concentrate on the reason. Mainly because the size of the rivet and the gun nozzle does not match, can not enter the track smoothly. Or the feeding track is blocked. It is also possible that the inside of the rivet gun is not lubricated enough.

How to Solve?

The solution is also simple. Use the right size rivets, clean the feed rail of the rivet gun and make the riveting gun

10. Unstable Performance of the Rivet Gun

If you are experiencing this problem below, the rivet gun performance is unstable when using the rivet gun. Sometimes it pulls the rivets correctly and sometimes it doesn’t work properly. Then there is both the possibility that the rivet gun has been used for too long and is more worn out. And lack of maintenance. If all of the above are not a problem, then it is the air pressure is not stable.

How to Solve?

The solution is as follows:

- Regular maintenance of the rivet gun

- Check air pressure before use

- Check for badly worn internal parts

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Rivet Gun Failure Prevention Recommendations and Daily Maintenance

Most riveting gun failures are caused by tool wear that has not been inspected, insufficient lubrication, tension deviation, or improper use. Establishing a scientific maintenance plan and standard operating procedures (SOP) is the basis for ensuring stable equipment operation and avoiding sudden failures.

Ⅰ. Preventive measures in daily operations

1. Proper use of posture and riveting rhythm

- Avoid applying force at an angle; ensure that the rivet core is pulled vertically

- The riveting rhythm should be stable; avoid sudden force or repeated pulling of unbroken rivet cores

2. Select rivet heads and pliers of appropriate specifications

- Different rivet diameters and head shapes require corresponding rivet heads

- Replace pliers jaws promptly after wear to prevent rivet core slippage or jamming

3. Confirm pull force values

- Regularly use pull force test sheets (breakage samples) to confirm output meets rivet core breakage requirements

- Especially when using structural rivets or high-strength rivets, consistency in core breakage must be strictly controlled

II. Maintenance and Inspection Points (Recommended for Inclusion in Equipment Inspection Procedures)

1. Pneumatic Rivet Gun Maintenance

- Drain moisture daily to prevent water vapor from entering the gun body and corroding internal parts.

- Check the air intake filter weekly to prevent debris from clogging the pressure regulator.

- Regularly apply specialized pneumatic lubricant to the gun body to extend the lifespan of the seals and piston.

2. Hydraulic riveting gun maintenance

- Regularly check the hydraulic system for leaks or unstable pressure.

- Clean the oil pipes before replacing the hydraulic oil to prevent particles from damaging internal components.

- Check the wear condition of the sealing rings and return springs, and replace them if necessary.

3. Manual riveting gun maintenance

- Clean surface oil stains and debris daily to prevent clamping jaw jamming.

- Periodically disassemble the clamp jaw seat to remove aluminum shavings, copper shavings, and other debris residue.

Ⅲ. Establish standard operating procedures (SOP) and recording mechanisms.

- It is recommended to create a riveting gun usage log card to record usage frequency, maintenance times, and fault conditions.

- In high-frequency usage scenarios (such as production lines), backup equipment should be set up and used on a rotating basis to avoid continuous overload.

- For critical connections (such as structural components and seals), random inspections or riveting consistency reviews should be performed once every quarter.

Riveting Tool Selection and Alternative Recommendations

In riveting operations, the choice of riveting tools directly affects assembly quality, work efficiency, and operator comfort. The selection of tools should be based on a comprehensive assessment of rivet type, installation strength requirements, batch size, space constraints, and operator skill level. Incorrect tool selection not only leads to low efficiency but may also cause structural defects and frequent failures.

Comparison of the applicability of different types of riveting guns

| Tool Type | Application Scenario | Advantages | Limitations |

|---|---|---|---|

| Manual Rivet Gun | Small batches, repairs, on-site or DIY use | Low cost, portable, no air supply needed | Low force, operator fatigue, low speed |

| Pneumatic Rivet Gun | Medium to large-scale sheet metal assembly | High efficiency, ideal for standard rivets | Requires stable air supply, higher maintenance |

| Hydraulic Rivet Gun | Structural and large-diameter rivet installation | High pulling force, reliable mandrel break | Heavy, high cost, requires skilled use |

| Battery-Powered Rivet Gun | Mobile service, field work, flexible assembly | No air supply, stable torque, automation-ready | Battery life limits, higher cost |

| Automatic Riveting Machine | High-speed production lines (e.g., appliances, automotive) | Auto-feed, consistent quality, very fast | High initial cost, low flexibility |

Alternative recommendations for special operating conditions

In special operating conditions, traditional rivet guns often fail to meet assembly requirements, necessitating the flexible adoption of alternative solutions. For example, in cases involving multi-layer structures or high-strength requirements, structural rivets should be used in conjunction with hydraulic or electric rivet guns. In confined spaces, slender pneumatic rivet guns or compact electric guns should be selected. For waterproof structures, closed-type rivets with sealing washers are recommended. For removable components, a rivet nut system should be used instead of disposable pop rivets.

For companies, it is recommended to establish a “rivet type-rivet gun configuration” standard table to clearly define the tool models and operating parameters corresponding to different specifications. It is advised to configure backup rivet guns at critical workstations to ensure uninterrupted production; important processes should undergo regular tensile calibration and maintenance. By standardizing tool selection and alternative strategies, not only can failure rates be reduced, but assembly consistency and production efficiency can also be significantly improved.

Conclusion

In fact, in the use of rivet gun is possible problems far more than the above listed 10 kinds. There are all sorts of strange problems that can occur.

There are just a few reasons: damaged parts, lack of lubrication, incorrect air pressure and mismatched rivet sizes. In the actual use of the process, adhere to the above points, basically can solve 80% of the problems of the rivet gun.

If you do not know how to solve your rivet gun problems, please contact our engineers!

Order High Quality Rivet Guns from Rivmate

The root of the solution to all the problems of the rivet gun is two things: 1. a high-quality rivet gun 2. reassuring after-sales service. As it happens, Rivmate can provide you with both.

If you want to buy a high quality rivet gun, please send us a quote.