Table of Contents

Rivet assembly is an essential part of the rivet production process. Do you know how blind rivets are assembled? Do you know Blind Rivet assembly process and what are the points of attention?

Table of Contents

What is Blind Rivet Assembly?

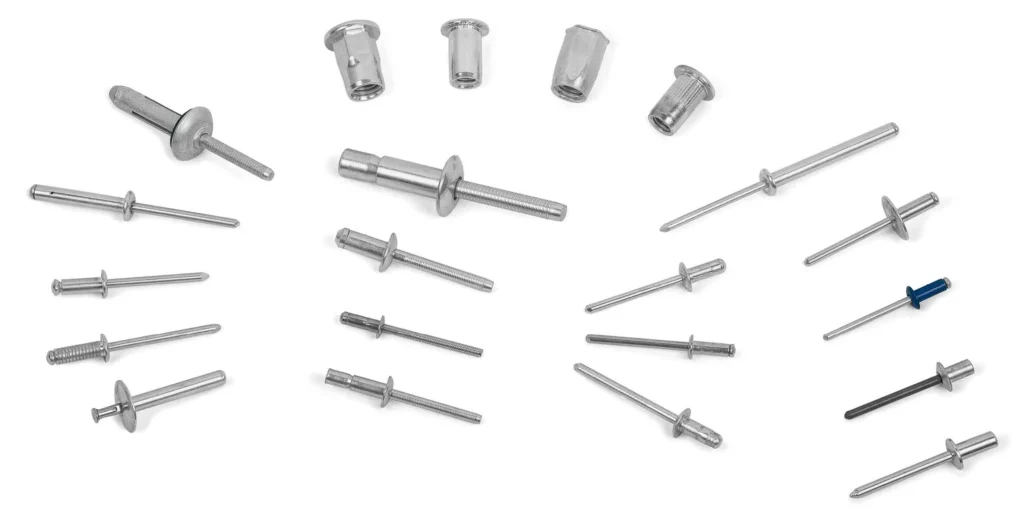

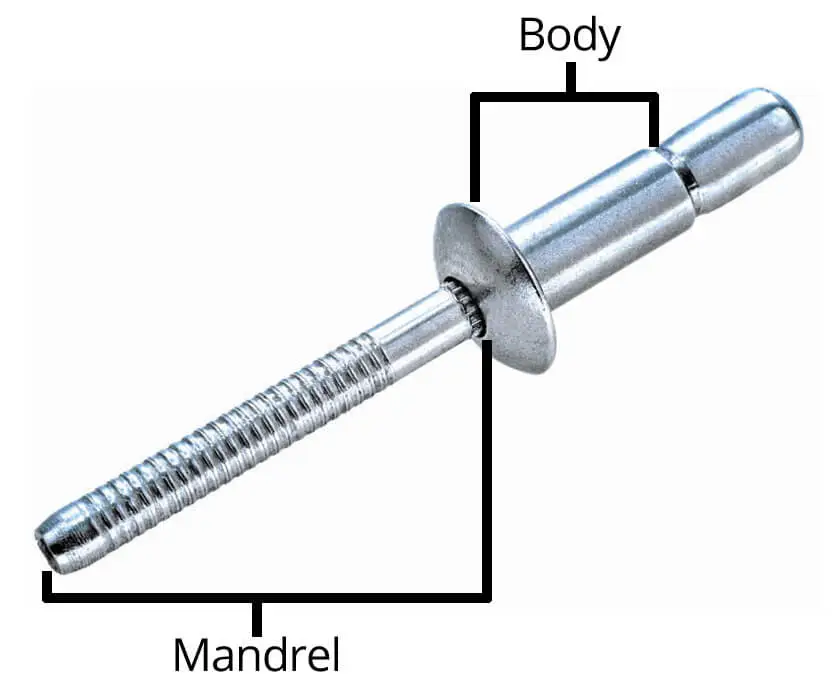

As we all know, Blind Rivet consists of two parts: 1.Rivet body 2.Mandrel. In the production process of blind rivets, these two parts are produced separately, after the production is completed, the machine will be used to assemble this part together.

The purpose of this assembly process is to firmly embed the mandrel into the rivet body so that it becomes one piece. This allows the blind rivet to be riveted in its final use. Assembled Blind Rivets can be used directly for joining a wide variety of materials and structures, especially where there is only room for one-sided operation, such as joining sheet metal, plastic parts and composites.

4 Steps for Blind Rivet Assembly Process

The Blind Rivet assembly process is divided into four main steps. From the preparation before assembly to the inspection after the assembly is completed are the necessary steps.

1. Prepare Rivet Body and Mandrel

Before proceeding with formal blind rivet assembly, the rivet manufacturer needs to ensure that the dimensions of the rivet body and mandrel are matched. The shape and material meet the customer’s requirements and are free from defects or contamination.

It is important to note that rivet bodies are usually made of aluminum, stainless steel and other materials. And in order to achieve better riveting results, the mandrel is usually a harder material than the rivet body.

In the assembly process of the actual production, the use of automated assembly equipment is required.In order to achieve excellent assembly results in one go, engineers need to ensure the precision and cleanliness of the assembly equipment.

2. Insertion Rivet Mandrel

Once the equipment, rivet body and mandrel dimensions are OK, the insertion of the mandrel will be performed.

The precision insertion force control of the assembly machine will slowly insert the mandrel into the open end of the rivet body. This process ensures that there is no tilting or distortion during insertion. The key to this step is to control the insertion force to avoid damage to the rivet body or core.

In addition to this, the assembler will monitor the depth and position of the rivet core insertion in real time. Strict control ensures that each rivet assembly achieves the specified insertion depth, guaranteeing rivet quality and consistency.

3. Fixed Rivet Mandrels

Simply inserting the mandrel into the rivet body will not make the rivet very strong. It is important to keep the assembly stable at this time.

The machine will apply a slight pre-pressure to the rivet mandrel to stabilize the mandrel in the rivet body and prevent it from loosening or falling out during subsequent operations.

After installation, the fixing points need to be checked and Rivmate’s automatic rivet assembly machines are equipped with a checking device that checks the fixing position and tightness of the mandrel to ensure that the rivet core is stable and free from loosening in the rivet body.

4. Quality Control

International quality standards have a tight tolerance for blind rivets. For example, DIN 7337 Blind Rivets have a tolerance between -0.1 ~ 0.0. Therefore, after the assembly is completed, it is usually necessary to use a machine to automatically check whether the rivet assembly meets the tolerance requirements. Items checked include alignment, exposed core length, integrity of the rivet body, etc.

Sample testing is also performed to ensure that our customers receive high quality blind rivets. A randomly selected portion of the rivet assembly is subjected to a tension test to verify the reliability and robustness of the assembly.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How Does the Assembly of the Rivet Body and Mandrel Ensure Firmness?

- To achieve an excellent rivet assembly, the inside diameter of the rivet body and the outside diameter of the mandrel must be within tight tolerances. This ensures that the core is tightly embedded in the rivet body. Tolerances that are too large may cause loosening, while tolerances that are too small may damage the rivet body or mandrel during assembly.

- In addition, the length of the mandrel should be such that it is moderately exposed during assembly and can be easily gripped by the riveting tool. When assembling, it is necessary to ensure that the mandrel is embedded in the same depth to ensure that the tightening effect of each rivet is consistent.

- Usually the hardness of the rivet body and the mandrel are differentiated. The hardness of the mandrel needs to be greater than that of the rivet body so that it can break smoothly during the riveting process and form a tight joint.

- Check the embedding depth of the assembled mandrel to ensure that it meets the standard requirements. Check the integrity of the rivet body to avoid poor assembly due to excessive pressure or deformation.

FAQs

What Causes an Arbor to Loosen or Fall Off Easily During Assembly?

There are a number of reasons why this can happen, and here are a few common ones:

- Dimensional tolerances do not meet the requirements

- Insufficient insertion force of assembly equipment

- Mismatch of hardness between mandrel and rivet body material

- Smoothness of the mandrel surface is too high

- Poor alignment of the assembly

- Poor initial fixing

If a Rivet Body is Deformed During Assembly, What are Some Common Causes?

Deformation of the rivet body during assembly can be caused by a variety of reasons. The following are some of the common causes.

- Excessive or uneven insertion force

- Rivet body and mandrel size mismatch

- Insufficient hardness of the rivet body material

- Poor alignment during assembly

- Excessive assembly speed

- Rivet body quality defects

- Inappropriate temperature or environmental conditions

What Should be Done if the Arbor is Tilted or not Smoothly Embedded in the Rivet Shell After Assembly?

Tilting of mandrels or failure to embed smoothly in rivet shells during assembly is usually caused by dimensional mismatch, poor alignment, improper surface treatment, improper setting of equipment parameters or contamination by impurities. By strictly controlling the tolerance, ensuring alignment, adjusting the insertion force, optimizing the material and assembly conditions and other measures, the problems of tilting and poor embedding of the mandrel can be effectively solved, thus ensuring a smooth assembly process and stable quality.

Wholesale High Quality Blind Rivets from Rivmate

Rivmate is a top manufacturer of Blind Rivets in China. We have strict control over the Blind Rivet assembly process to ensure that the Blind Rivets we produce are of high quality.

If you want to enhance your business with high quality blind rivets, contact us today!