Table of Contents

There are many types of rivet colors, do you know what kind of rivet colour you should be? This guide is the most comprehensive guide on rivet colour selection.

By reading this post, you will learn what coloured rivets are and what rivet colours do. Let’s read on together!

Table of Contents

What are Colored Rivets?

Colored rivets are rivets with a specially coated or oxidised coloured surface. coloured pop rivets not only provide the strength of standard rivets, but also offer the aesthetics, corrosion resistance and specific environmental suitability that a product requires. Coloured rivets are manufactured from a variety of raw materials including aluminium, stainless steel, steel and plastic. Manufacturers give rivets different colours by painting, anodising, plating or powder coating.

Main Features of Colored Pop Rivets

- Aesthetics: can match the colour of the connected materials for a more coordinated appearance.

- Corrosion resistance: Specific coatings (e.g. anodising, powder coating) can improve the weathering resistance of rivets and prevent rusting or fading.

- Identification of use: Different rivet colours can be used to identify different uses, installation locations or material types.

- Wide range of colour options: Common colours include black, white, red, blue, green, silver, etc. and specific colours can be customised.

What is the Standard for Rivet Colors?

There is usually no globally uniform mandatory specification for rivet colour standards, but there are some common colour matching rules or standards that may be followed in different industries, manufacturers and applications. Below are the main standards and guidelines for blind rivet colours.

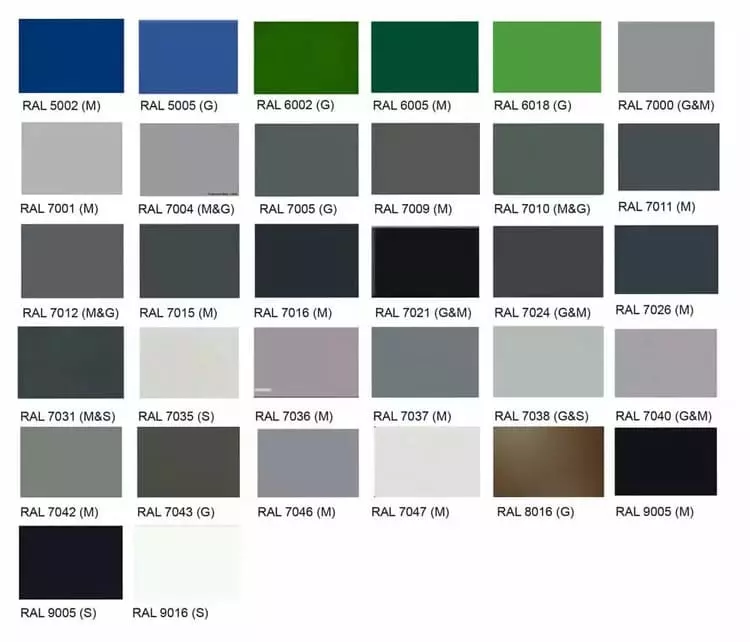

RAL Colour Standard

European manufacturers usually use the RAL colour system (German standard colour card), e.g.:

- RAL 9016 (white) – building and window applications

- RAL 9005 (black) – industrial equipment

- RAL 3020 (red) – safety signs, fire protection equipment

Pantone Colour Matching System

Some manufacturers allow customers to choose rivet colours based on Pantone colour codes, especially in industries where custom branding or product appearance is critical.

ANSI and ASTM Standards

ANSI and ASTM do not have uniform rivet colour regulations, but some construction, aerospace and automotive manufacturers may have internal standards.

Aerospace & Defence

In aerospace and military applications, colours may be used to differentiate between different grades or uses of rivets, for example:

- Green (Olive Drab) – military equipment

- Black (Black Oxide) – corrosion resistant coatings

Do You Have Any Questions?

Let Us Solve Your Problem

Why Use Colored Rivets?

In practice, we often encounter the use of blind rivets with specified colours. So why use coloured blind rivets? Here are the main reasons I summarise.

1. Visual Aesthetics & Colour Matching

One of the main advantages of coloured rivets is their aesthetic appearance. Coloured rivets can match the colour of the product or structure, enhancing the overall design of the product.

High-end Product Appearance Enhancement

- Electronic products (such as notebooks, server chassis), home appliances (such as air conditioners, washing machines), etc., the use of rivets with the same colour as the body, so that the overall design is more neat.

- In the field of luxury packaging or art decoration, special colour rivets such as gold, copper, black, etc. are used for high-end product packaging or display frame fixing to enhance the sense of brand value.

Colour Matching

- In the construction, decoration and furniture industries, rivets in common colours such as black, white and silver can blend in perfectly with window frames, doors, curtain walls, parapets, etc., avoiding abrupt bare-metal rivets from affecting the aesthetics.

- In automotive, motorbike and bicycle production, coloured rivets can be used for decorative assemblies such as bumpers, side skirts and body interiors to make the product more attractive.

2. Corrosion & Weather Resistance

Bare metal rivets are susceptible to oxidation and rust in harsh environments. Coloured rivets with surface coatings (e.g. powder coating, anodising, electroplating) provide additional protection and improve corrosion and weathering resistance.

Outdoor & Humid Environments:

- Building curtain walls, windows, doors, guardrails and other structures exposed to the elements for a long time, the need for colour rivets with strong anti-rust properties. For example, powder coated aluminium rivets or stainless steel coloured rivets.

- Ships, marine equipment need to resist salt spray corrosion rivets. Generally manufacturers choose stainless steel rivets with anodised finish for longer life.

Chemical & Industrial Environment:

- Chemical plants, food processing equipment, medical equipment require corrosion-resistant, non-contaminating rivets. So often use coated stainless steel rivets.

- High temperature environments (such as engine compartments, machinery and equipment) require high temperature resistant coated rivets to avoid oxidation and discolouration of bare metal at high temperatures.

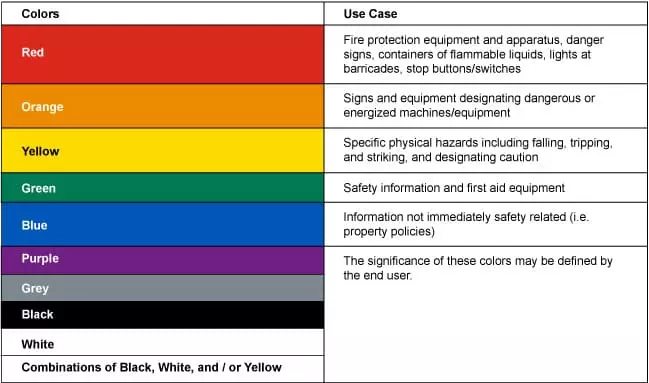

3. Colour Coding & Marking

Coloured rivets can be used as a marking tool in manufacturing, assembly and repair processes to help identify different components or process requirements, improving productivity and quality control.

Distinguishing Between Different Uses

- Red rivets are used in highly loaded structures to remind operators of the need for increased inspection.

- Blue rivets are used in lightly loaded areas to avoid wasting high-strength rivets.

- Green rivets are used for environmentally friendly or specific materials for ease of management.

Safety Alerts & Foolproof Assembly

- In electrical equipment, red rivets may be used in high voltage areas, while blue or green rivets are used in low voltage areas to minimise misuse.

- In aerospace and rail, different coloured rivets are used to mark structural significance and ensure that critical components are not incorrectly replaced during maintenance.

Easy Maintenance & Tracking

- In the automotive, home appliance and machinery sectors, colour-coded rivets can be used to differentiate between service batches and help after-sales repairs to quickly locate the problem area.

4. Concealment & Low Visibility

In some applications, it is desirable for the rivet fixing points to be inconspicuous or non-reflective to enhance the concealment or aesthetics of the product.

In high-end homes, curtain wall decorations and exhibition displays, users often choose to use rivets in the same colour as the background. This makes the joints less noticeable and gives the building and furniture a cleaner overall look.

5. Enhanced Durability & Mechanical Properties

The vast majority of coatings do more than just add colour, they provide rivets with additional resistance to wear, impact and scratches. As a result coloured pop rivets generally have a longer service life.

Anodized aluminium rivets have a harder surface, which can effectively reduce friction damage, and are suitable for high-frequency use or frequently disassembled equipment.

Powder coated aluminium rivets are more resistant to abrasion and impact, and are suitable for mechanical equipment, toolboxes and other products that require frequent operation.

The weather resistance of coloured rivets means longer product life and reduced replacement and maintenance costs. Therefore, outdoor billboards, traffic facilities, building fixtures and other long-term use of the scene will use coloured rivets.

Applications of Colored Rivets

Of course coloured pop rivets are very widely used. Because it is coated with different rivet colours, it not only has the function of connecting and fixing, but also enhances the aesthetic appearance of the product. Below are a few specific applications of coloured pop rivets.

- Automotive industry: body decoration. For example, car doors, car seats, bonnets.

- Home appliance industry: for the exterior assembly of home appliances, fixing and decoration of visible parts.

- Electronic products: to enhance the aesthetics or decoration of audio equipment.

- Advertising representation and display: fixed billboards, outdoor display boards, signage, etc.

- Construction industry: wall decoration, furniture design, metal frames and metal doors and windows can be connected by coloured rivets.

Do You Have Any Questions?

Let Us Solve Your Problem

How to Select Rivet Colors?

When picking rivet colours, in addition to the appearance needs and aesthetic factors, you need to choose the right colour rivets based on the application scenario. Here are a few key factors to consider when picking rivet colours:

1. Functional Requirements

Blind Rivets will be coated to achieve or enhance several special properties:

- Anti-corrosion

- High temperature resistance

- Ultraviolet (UV) resistance

- Abrasion resistance

Black coatings (e.g. epoxy or polyurethane coatings) are usually very resistant to corrosion and it strengthens the rivet’s resistance to corrosion. Grey or gold coatings (e.g. aluminium plating or anodised aluminium) allow the rivet to maintain good stability at high temperatures. Choosing a coating with UV protection (e.g. grey or black coating) can extend the life of the rivet and prevent the coating from fading.

2. Aesthetic and Branding Requirements

In many product applications, manufacturers will require coloured rivets to match the product colour. This enhances the aesthetics of the product. For example, in high-end electronics or automotive manufacturing, coloured rivets need to be colour-coordinated with the product casing, accessories or other components. Common colours include black, silver, gold, blue and white.

Of course, rivets can be very concealable when the colour of the rivet matches the colour of the material or housing. You can effectively avoid the rivets being conspicuous.

3. Material and Coating Selection

Different colours of rivets may have different coatings or treatments, not only affecting the appearance, but also directly affecting the performance of the rivets.

- Anodized Aluminium Coating: Usually provides a wide range of colours for aluminium rivets, such as black, gold, blue, red, etc. Anodized rivets have excellent corrosion resistance.

- Powder Coating: Suitable for steel, aluminium, copper and other materials, powder coated rivets can provide a thicker protective layer, the colour options are very rich.

- Electroplated coatings: coatings such as chrome plating, zinc plating, etc., usually provide more durable corrosion resistance, suitable for applications requiring high corrosion resistance.

Do Rivet Colors Affect Rivet's Function?

The colours of pop rivets are mainly achieved through surface coating or plating techniques, so rivet colours do not usually come back to directly affect the basic function of the rivet. However, rivet colours may have an impact on the performance of the rivet in a particular scenario or other requirements.

The colour of rivets is often achieved through coatings such as spraying, anodising or painting. Certain coatings (e.g. corrosion-resistant coatings) not only provide colour to the rivet, but also enhance the rivet’s corrosion resistance.

In addition to this, in some special processes (e.g. anodised aluminium rivets), the thickness and quality of the coating may have a slight effect on the surface hardness of the metal. For example, anodised aluminium not only provides colour, but also forms a hardened oxide layer on the surface of the aluminium, increasing its wear resistance.

Do Rivet Colors Coating Flake or Fade Easily?

This issue depends largely on the type and quality of the coating, as well as the environment in which it is used. Different coating processes and materials can have a significant impact on the durability, fade and peel resistance of rivets.

Custom Rivet Colors for your Project from Rivmate

In order to make your products more competitive, whether the rivet colour matches or not is an important thing. Rivmate is the top coloured rivets manufacturer in China, you can customize any colour of blind rivets for your project.

We will send you the rivet samples for confirmation before formal order.