RIVMATE BOM Rivet

Rivamte Fastener – Top Fastener Maker in China

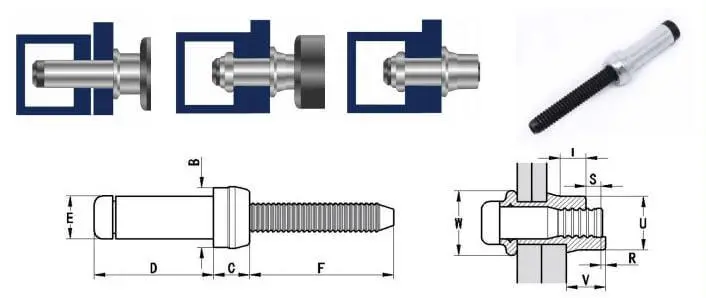

Boom-Lock Type Blind Rivet

Boom-Lock Type Blind Rivet is a structural mandrel rivet featuring a reliable locking mechanism. Once installed, the mandrel is securely locked within the rivet body, maintaining stable connections under vibration or dynamic loads. It is suitable for industrial applications demanding high strength and safety.

- Mandrel Material

This rivet utilizes a Carbon Steel / Carbon Steel mandrel configuration. During installation, it delivers stable tensile strength and locking performance - Surface Treatment

The surface features Green Trivalent Electroplating Blue White Zinc - Diameter Range

Product diameters span 4.8 mm (3/16“) to 12.7 mm (1/2”), accommodating diverse assembly requirements from medium to high loads. - Quality Certification

Manufactured in compliance with ISO Quality Management System and IATF Quality System Certification requirements

How Does a BOM Rivet Work?

BOM Rivet achieves reliable single-side installation connections through a structural locking mechanism. During installation, the tool pulls the mandrel, causing the rivet sleeve to expand and conform to the hole wall on the workpiece’s reverse side in a controlled manner, forming a stable load-bearing structure. When the tensile force reaches the preset value, the mandrel fractures at the predetermined fracture line, completing the installation.

Its core feature is that the mandrel is fully locked and retained within the rivet body, preventing loosening or detachment. This enhances vibration resistance and long-term connection reliability. Compared to standard blind rivets, BOM Rivet demonstrates greater stability under shear and tensile conditions.

Advanced Manufacturing Technology

Our products use the world’s advanced production technology and surface treatment. Capable of providing high strength connections. High-quality raw materials improve corrosion resistance. Have strong durability.

Complete Specifications

High-quality Materials

Exquisite Workmanship

Technical Specification of Rivmate Boom Rivets

| Part Number | Diameter | Art. Code | Grip Range(Min) | Grip Range(Max) | Drill Diameter(Min) | Drill Diameter(Max) | Shear Force | Tensile Force |

|---|---|---|---|---|---|---|---|---|

| SSBOOM48095 | 4.8(3/16") | SSBOOM-00602 | 2.4 | 4.0 | 5.3 | 5.65 | 12400N | 8000N |

| SSBOOM48111 | SSBOOM-00603 | 4.0 | 5.6 | |||||

| SSBOOM48127 | SSBOOM-00604 | 5.6 | 7.2 | |||||

| SSBOOM48143 | SSBOOM-00605 | 7.8 | 8.8 | |||||

| SSBOOM48159 | SSBOOM-00606 | 8.8 | 10.3 | |||||

| SSBOOM48175 | SSBOOM-00607 | 10.3 | 11.9 | |||||

| SSBOOM48190 | SSBOOM-00608 | 11.9 | 13.5 | |||||

| SSBOOM48206 | SSBOOM-00609 | 13.5 | 15.1 | |||||

| SSBOOM48222 | SSBOOM-00610 | 15.1 | 16.7 | |||||

| SSBOOM48238 | SSBOOM-00611 | 16.7 | 18.3 | |||||

| SSBOOM48254 | SSBOOM-00612 | 18.3 | 19.9 | |||||

| SSBOOM64116 | 6.4(1/4") | SSBOOM-00802 | 2.8 | 4.0 | 7.1 | 7.4 | 22700N | 14500N |

| SSBOOM64132 | SSBOOM-00803 | 4.0 | 5.6 | |||||

| SSBOOM64148 | SSBOOM-00804 | 5.6 | 7.2 | |||||

| SSBOOM64164 | SSBOOM-00805 | 7.2 | 8.8 | |||||

| SSBOOM64180 | SSBOOM-00806 | 8.8 | 10.3 | |||||

| SSBOOM64196 | SSBOOM-00807 | 10.3 | 11.9 | |||||

| SSBOOM64212 | SSBOOM-00808 | 11.9 | 13.5 | |||||

| SSBOOM64228 | SSBOOM-00809 | 13.5 | 15.1 | |||||

| SSBOOM64243 | SSBOOM-00810 | 15.1 | 16.7 | |||||

| SSBOOM64259 | SSBOOM-00811 | 16.7 | 18.3 | |||||

| SSBOOM64275 | SSBOOM-00812 | 18.3 | 19.9 | |||||

| SSBOOM80176 | 8.0(5/16") | SSBOOM-01004 | 4.8 | 7.9 | 8.85 | 9.35 | 35800N | 23100N |

| SSBOOM80208 | SSBOOM-01006 | 7.9 | 11.1 | |||||

| SSBOOM80240 | SSBOOM-01008 | 11.1 | 14.3 | |||||

| SSBOOM80271 | SSBOOM-01010 | 14.3 | 17.5 | |||||

| SSBOOM80303 | SSBOOM-01012 | 17.5 | 20.6 | |||||

| SSBOOM80335 | SSBOOM-01014 | 20.6 | 23.8 | |||||

| SSBOOM80367 | SSBOOM-01016 | 23.8 | 27.0 | |||||

| SSBOOM80194 | 10.0(3/8") | SSBOOM-01204 | 4.8 | 7.9 | 10.5 | 11.05 | 49400N | 32300N |

| SSBOOM80226 | SSBOOM-01206 | 7.9 | 11.1 | |||||

| SSBOOM80258 | SSBOOM-01208 | 11.1 | 14.3 | |||||

| SSBOOM80289 | SSBOOM-01210 | 14.3 | 17.5 | |||||

| SSBOOM80321 | SSBOOM-01212 | 17.5 | 20.6 | |||||

| SSBOOM80353 | SSBOOM-01214 | 20.6 | 23.8 | |||||

| SSBOOM80385 | SSBOOM-01216 | 23.8 | 27.0 | |||||

| SSBOOM80416 | SSBOOM-01218 | 27.0 | 30.2 | |||||

| SSBOOM80448 | SSBOOM-01220 | 30.2 | 33.3 | |||||

| SSBOOM127254 | 12.7(1/2") | SSBOOM-01604 | 6.4 | 9.5 | 13.9 | 14.75 | 89600N | 57800N |

| SSBOOM127285 | SSBOOM-01606 | 9.5 | 12.7 | |||||

| SSBOOM127317 | SSBOOM-01608 | 12.7 | 15.9 | |||||

| SSBOOM127349 | SSBOOM-01610 | 15.9 | 19.1 | |||||

| SSBOOM127381 | SSBOOM-01612 | 19.1 | 22.2 | |||||

| SSBOOM127412 | SSBOOM-01614 | 22.2 | 25.4 | |||||

| SSBOOM127444 | SSBOOM-01616 | 25.4 | 28.6 | |||||

| SSBOOM127476 | SSBOOM-01618 | 28.6 | 31.8 | |||||

| SSBOOM127508 | SSBOOM-01620 | 31.8 | 34.9 | |||||

| SSBOOM127539 | SSBOOM-01622 | 34.9 | 38.1 | |||||

| SSBOOM127571 | SSBOOM-01624 | 38.1 | 41.3 |

Key Features of BOM Rivet

Structural Locking Mechanism

Features a structural locking design that securely locks and retains the mandrel inside the rivet after installation, effectively preventing loosening or detachment to enhance connection safety.

High Shear Strength

BOM Rivet delivers stable and high shear load capacity, suitable for structural connections subjected to lateral forces.

High Tensile Strength

Exhibits excellent tensile performance under axial loads, maintaining secure fastening and reducing failure risks from tensile stress.

Excellent Vibration Resistance

The locking mechanism effectively resists vibration and dynamic loads, maintaining connection stability in long-term operational environments.

Single-Side Installation Capability

Supports single-side installation, suitable for structures with inaccessible backsides, enhancing assembly flexibility and efficiency.

Consistent Installation Quality

Tool-controlled tension ensures uniform clamping force and assembly quality during mass production, minimizing human error.

How to choose reilable supplier of Bom rivets?

Own Manufacturing Factory

Ownership of a manufacturing facility is the primary criterion for selecting a BOM Rivet supplier. Having an in-house factory enables the supplier to exercise full control over raw materials, production processes, and quality inspection, ensuring batch consistency and long-term stability of BOM Rivets. Suppliers without their own facilities often struggle to deliver consistent quality over time.

International Quality Certifications

Reliable BOM Rivet suppliers should hold international quality system certifications such as IATF 16949:2016 and ISO Quality Management Systems. These certifications represent essential thresholds in the automotive and industrial fastener sectors, demonstrating that suppliers maintain standardized quality management processes and traceable production systems.

Comprehensive Product Range

Different projects demand significant variations in BOM rivet specifications, including diameter, clamping range, material, and surface treatment. Premium suppliers maintain a complete product specification system covering diverse applications, minimizing customer need to switch suppliers due to insufficient offerings.

Customization Capability

Beyond standard specifications, reliable BOM Rivet suppliers should offer customization services, including non-standard dimensions, special materials, or project-specific designs. This capability ensures precise alignment with assembly requirements, enhancing overall connection reliability.

Long-Term Supply Stability

BOM Rivets are typically used in high-strength and critical structural connections, making stable supply essential. Suppliers with long-term supply capabilities effectively reduce project risks and additional costs caused by delivery instability.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

BOM Rivet vs Other Fasteners

| Comparison Item | BOM Rivet | Standard Blind Rivet | Monobolt Rivet | Lockbolt |

|---|---|---|---|---|

| Installation Type | Blind, single-side | Blind, single-side | Blind, single-side | Double-side (or special tooling) |

| Structural Level | Structural | Non-structural | Structural | Heavy structural |

| Mandrel Retention | 100% retained and locked | Mandrel breaks and may fall out | 100% retained and locked | No mandrel (pin & collar system) |

| Shear Strength | High | Low to medium | Very high | Extremely high |

| Tensile Strength | High | Low | Very high | Extremely high |

| Vibration Resistance | Excellent | Limited | Excellent | Outstanding |

| Installation Consistency | High (tool-controlled) | Medium | High | Very high |

| Typical Applications | Automotive, machinery, frames | Light panels, housings | Heavy equipment, vehicles | Bridges, rail, heavy steel |

| Cost & Efficiency Balance | Balanced | Low cost | Higher cost | Highest cost |

In structural joining applications, BOM Rivets occupy a position between standard blind rivets and heavy-duty structural fasteners, balancing strength, installation efficiency, and cost control.

- BOM Rivet vs Standard Blind Rivet: BOM Rivet features a structural locking design with full mandrel retention, delivering superior shear and tensile performance along with enhanced vibration resistance; standard blind rivets are only suitable for light loads and non-critical connections.

- BOM Rivet vs Monobolt Rivet: BOM Rivet offers slightly lower ultimate strength but provides more controllable costs and universal specifications; Monobolt Rivets suit higher loads and more demanding conditions.

- BOM Rivet vs Lockbolt: BOM Rivets support single-side installation for higher assembly efficiency; Lockbolts offer greater structural strength but involve complex installation and higher overall costs, primarily used in heavy-duty permanent structures.

Typical Applications of BOM Rivets in Structural Fastening

Automotive & Commercial Vehicles

BOM Rivets are extensively used in body structures, chassis attachments, and bracket connections for automobiles and commercial vehicles. Their structural locking and mandrel retention design helps maintain connection stability under vibration and dynamic loads, meeting the automotive industry’s requirements for consistency and reliability.

Construction Machinery & Heavy Equipment

In construction machinery and heavy equipment, BOM Rivets are frequently employed in structural components subjected to high shear and tensile loads. Compared to standard blind rivets, their superior structural performance effectively reduces loosening risks, making them suitable for long-term, high-load operating conditions.

Steel Structures & Industrial Frames

BOM Rivets are suitable for assembling steel structures and industrial frames, particularly in situations where the backside is inaccessible. Their single-side installation capability significantly improves construction and assembly efficiency while ensuring reliable structural connections.

Rail Transit Systems

In rail transit applications, BOM Rivets are commonly used for vehicle body structural components, equipment mounts, and non-welded connections. Their excellent vibration resistance and consistent installation quality help meet the safety requirements for long-term operation of rail vehicles.

Energy Equipment & Infrastructure

In energy equipment and related infrastructure—such as power generation casings and support structures—BOM Rivets maintain structural integrity while reducing maintenance needs, making them ideal for applications requiring long-term stable operation.

Industrial Manufacturing & Assembly Lines

On industrial manufacturing and assembly lines, BOM Rivets’ tool-controlled installation delivers consistent clamping force and high repeatability. This makes them suitable for mass production, boosting assembly efficiency while minimizing human error.

FAQs - BOM Rivet

Q1: What Is a BOM Rivet?

BOM Rivets are structural hollow rivets featuring a reliable locking mechanism. Upon installation, the mandrel remains securely locked within the rivet body, providing stable structural connections even under single-side installation conditions.

Q2: What Applications Are BOM Rivets Used For?

BOM Rivets are primarily used in applications demanding high strength and reliability, such as automotive and commercial vehicles, construction machinery, steel structures, and industrial frameworks. They are particularly suited for structural connections where the backside is inaccessible.

Q3: How Strong Are BOM Rivets?

BOM Rivets deliver high shear and tensile strength, significantly exceeding standard pop rivets to meet structural-grade connection requirements. However, their strength typically falls below heavy-duty fasteners like Monobolt Rivets or Lockbolts.

Q4: How Are BOM Rivets Installed?

BOM Rivets are installed from a single side using specialized riveting tools. The installation process is controlled by tool tension, ensuring consistent clamping force. The mandrel fractures and locks upon reaching the preset tension, completing a stable connection.

Q5:How Do BOM Rivets Compare with Other Fasteners?

Compared to standard blind rivets, BOM Rivets offer superior strength and vibration resistance. Compared to Monobolt Rivets, they provide more controllable costs and greater versatility. Compared to Lockbolts, they deliver higher installation efficiency and the advantage of single-side installation.