Home » Clinch Fastener | Self Clinching Fasteners | Rivmate Fastener

Self Clinch Fastener

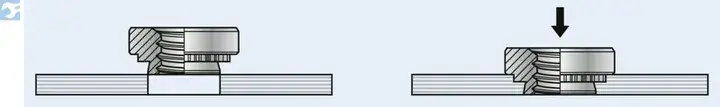

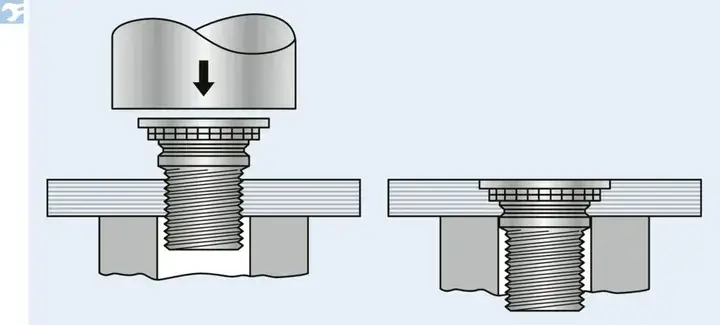

Self clinch fastener is easy to install. For sheet metal parts, due to the plate thickness is usually thin, do not have the conditions of direct tapping. Welding nuts is more troublesome and costly, thus and emergence of the pressure riveting process. Self clinch fastener technology usually involves self clinching nuts, self clinching studs and other parts to sheet metal parts. Through the role of external forces, the self clinching fastener will be squeezed into the prefabricated groove, to achieve a solid connection between the two parts.

Installation is accomplished by simply inserting the self clinch fastener into the pre-prepared hole in the desired location and orientation. Applying pressure using the appropriate installation tool.

Friction is formed on the contact surfaces of the self clinch fastener.The friction allows the self clinch fastener to be stressed and pressed into the body of the workpiece. And provides a large surface area to increase the strength of the connection. At the same time, the threaded and tabbed structures bite into each other to increase the robustness of the connection.

Self clinch fastener need to have the right amount of pressure applied to them for proper installation. That’s why it’s important to pay attention to how long and how hard the pressure is applied by the hydraulic press.

These self clinch nuts, self clinching standoffs, self clinching studs and other components are widely used by manufacturers of sheet metal, computers, medical, automotive manufacturing and aerospace solution systems among others.

Advantages of Self Clinching Fastener:

- Provides strong threads in sheet metal as thin as 0.012″/0.3 mm. More flexible design for installation into different materials of metal

- Can be mounted into normal round holes without any secondary operations. No special treatment of the mounting holes, such as chamfering and deburring, is required

- Installation using any parallel acting extrusion force. Low installation costs and shortening of the installation cycle with the help of in-mould capabilities

- Provides high push-out and spin-out forces. The reverse side of the metal plate remains flush

- Cleaner and more environmentally friendly process, no welding spatter, low energy consumption

Available in carbon steel, stainless steel, high quality stainless steel, aluminium and copper.

Self Clinching Nuts

- Self clinching nuts can be easily assembled.

- Providing a high-strength installation with just a simple press rivet, the

It is possible to keep the back of the sheet completely flat. - High torque resistance

- A variety of specifications, can meet a variety of design requirements

- Suitable for basically all electronic latter precision equipment

- No need to worry about the direction of installation

Self Clinching Studs

Self clinch studs are heat-treated and zinc-plated after production, so they have excellent corrosion resistance. Self clinch studs have a toothed embossing under the head, when pressed in, the substrate is deformed around the self clinching studs, and the toothed occlusion phenomenon occurs, thus forming a solid external thread.

Available in mild steel, stainless steel, aluminium and high quality stainless steel.

- Easy to assemble and requires only simple installation.

- High torque resistance

- Suitable for plated materials

Self Clinching Standoffs

Self clinching standoffs are widely used in metal plates, control boxes and power cabinets and other products wall plate inlay process. Its structure is special, when assembling, only need to put the nut post into the hole of the metal plate, with “pressure riveting” operation to achieve, has the following advantages:

- Enables length-guaranteed distance ranges, greatly simplifying the assembly process and accelerating the production of assembled pitch panels and fittings

- The backside of the plate remains completely flush, while ensuring that the head of the nut post is smooth against the flat surface of the plate

- Raw materials are free-cutting iron or free-cutting stainless steel

There are two types of self clinching standoffs:

- Through-Hole Threaded Standoffs

- Blind Threaded Standoffs

Self Waterproof Nuts

Self waterproof nuts are also known as sealed self clinching nuts or self waterproof nuts. The self waterproof nut has a blind internal thread with a head end equivalent to an S-type self clinching nut, which is fitted to the plate to form an effective internal nut. The blind hole design of the self waterproof nut effectively prevents the entry of external substances, and the product’s post can be used as a locating rod for the installation of other parts.

Self waterproof nut is divided into B type and BS type. B type material is carbon steel, surface treatment default for blue and white zinc. BS type material is stainless steel, surface treatment default stainless steel colour passivation treatment. SS304 or 303 Chin forging moulding, used in rust-proof workplaces, play a role in sealing waterproof.

Guidelines for the Use of Self Clinching Fasteners

Recommendations for installing self clinch fasteners

- Provide an appropriately sized mounting hole for each self clinch fastener

- Before installing self clinching fasteners, make sure they are in the holes

- Apply pressure while keeping in parallel surfaces

- When installing self clinch fasteners, apply sufficient installation force to process fasteners to be fully embedded throughout the hole.

Point of Attention:

- Do not install steel or stainless steel self clinch fasteners before surface treatment of aluminium panels

- Do not deburr the perimeter before installing the self clinch fastener – deburring consumes the metal used to fasten the fastener to the plate!

- Do not over squeeze. This will flatten the head, distort the threads and bend the plate. Experiment to determine the optimum installation pressure prior to production.

- Do not attempt to install self clinch fasteners with a hammer. There’s no way to install a flat with a hammer.

- Do not install self clinch fasteners in pre-coated panels

Rivmate Self Clinching Fastener Solutions

Rivmate has extensive experience in the production of fasteners. Rivmate has exported self clinching fasteners to more than fifty countries and is well recognised by our customers.

If you are interested in Rivmate’s specialised self clinch fastener solutions. Please contact your self clinching fastener specialist – Rivmate!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com