What is a Blind Rivet Used for? Applications of Blind Rivets

Table of Contents

Blind rivets are a common connecting fastener in the industrial sector and manufacturing. Then what is a blind rivet used for ? They play an important role in joining and reinforcing various material components. Whether it is in automotive manufacturing, aerospace industry, building structures or ship building, blind rivets play an important role.

In this blog, we’ll take an in-depth look at the uses and applications of blind rivets to help you understand why blind rivets are favored in many industries. We will look at how blind rivets work, their advantages and the scenarios in which they are used, and compare them to other fixing methods. Whether you are a professional engineer, manufacturer, or a blind rivet distributor, this article will provide you with valuable information and guidance to help you make informed decisions.

What are Blind Rivets?

The Blind Rivet, also known as the Pop Rivet, is a fastener designed for applications where access to the back of the material is not possible. Pop Rivets are very popular because they can join two or more pieces of material quickly and easily.

A pop rivet consists of two parts: the rivet body and the rivet stem. In the factory production process, the two parts of the blind rivet are produced separately and then assembled for use.

One of the greatest benefits of blind rivets is that there is no way to apply too much or too little pressure to the rivet. If selected properly, the rivet will work best in every installation.

What are Blind Rivets Work?

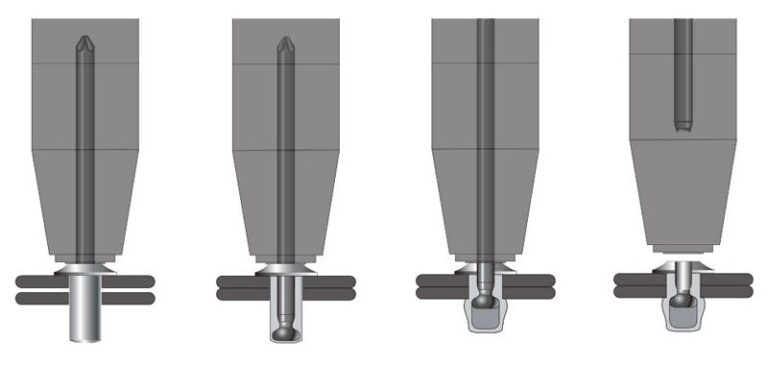

Blind rivets are a commonly used mechanical joining element that is connected by the breaking of the tail of the rivet body and the expansion of the shell. This type of connection is suitable for situations where operation can only be carried out from one side.

In the process of installing a blind rivet, the tool applies pressure and the tail of the rivet body deforms to form an expanding head, which will form a tight connection with the workpiece, thus firmly fixing the two workpieces together.

What are the Types of Blind Rivets ?

There are many types of blind rivets and they vary in strength and performance. Below I will give you a brief introduction to the various types of blind rivets:

Standard Blind Rivets have a rounded head, and when the mandrel is pulled, the tail of the rivet body deforms and expands, holding the material together in a stable manner. Standard blind rivets are the most widely used of the blind rivets. It is widely used in automotive, metal, construction, electrical appliances, furniture, containers, air conditioning and other industries.

The peel type blind rivet is a special type of blind rivet that uses the peel principle to make the connection. When the mandrel is dragged over, its tail becomes larger, leaving a tail with four petal shapes. This type of blind rivet is ideal for joining metal to softer materials, and its unique involvement does not damage the surface of the material. peel rivet works well in the construction industry for plasterboard, paint and insulation, and can be used in scenarios such as trailers, plastic parts, upholstery and more.

Sealed rivets are ideal for use in waterproof applications. These blind rivets have a sealed rivet body with the mandrel head enclosed in the rivet body even after installation.

Sealed rivets effectively prevent liquids and gases from entering or leaving the assembly after installation. They are used in the metal, construction and automotive industries. They may also be found in containers, furniture, air conditioning and heating systems, and electronics.

The function of a multi-grip blind rivet is similar to that of a standard blind rivet. multi-grip blind rivets have multiple indentations in the body of the rivet, which widen and provide multiple grips when the mandrel is pulled. This design makes it suitable for joining plastic to plastic and metal to metal.

Structural Blind Rivets work slightly differently than standard blind rivets. When a structural blind rivet is installed, it locks a portion of the mandrel into the body of the rivet. This creates an extra layer of fastening, which can effectively increase the strength of the rivet joint, as well as enhance the internal strength of the material.

The grooved Blind Rivet is a blind rivet best suited for softer materials such as plastics and wood. The grooves in this type of blind rivet provide great holding power and are often used to attach metal to building materials such as concrete, brick and wood.

One difference between a grooved blind rivet and a traditional blind rivet is that it does not have to go through the surface of the material. When its mandrel is pulled out, the grooves in the rivet body grip the material by friction.

What is a Blind Rivet Used for?

Blind Rivets are widely used in many fields because of their stable and fast characteristics. They are suitable for applications that require reliable connections and high strength load bearing.So what is blind rivets used for?

Application of Blind Rivets for Automotive Industry

The automotive manufacturing process requires a variety of connecting fasteners, and blind rivets are among the very commonly used fasteners. Blind Rivets have a variety of specific applications in the automotive industry. I have listed some of the application scenarios.

- Body Frame Connections:Sheet metal parts connecting the body structure

- Door and luggage compartment connection:Ensure the opening and closing function of doors and luggage compartments and withstand opening and closing forces and vibrations

- Engine cover connection: Prevents the engine cover from loosening or making noise while driving, ensuring the safety performance of the engine cover.

- Chassis and Suspension Connections: Ensuring stability and safety of the chassis and suspension system

- Connection of wheels and braking systems: The extractor rivets are able to withstand the forces of high speed rotation and braking, ensuring their stability and reliability.

Above I briefly listed some of the blind rivets in the automotive industry industry application scenarios, but the fact that the application of the scene far more than these. For example, blind rivets can be used to connect body parts, seats, airbag systems, exhaust systems and many other automotive components. If you are choosing blind rivets for your automotive project, you can contact our engineers.

Application of Blind Rivets for Solar Industry

Solar energy, as one of the main components of new energy, has been vigorously developed all over the world. This has brought about a large number of applications of solar energy equipment. However, the solar energy equipment can not be fixed and installed without blind rivets. Below I have listed some of the application scenarios of blind rivets in the solar industry.

- Solar Panel Mounting: Used for fixing solar panel brackets and support structures to ensure that the solar panels are securely fastened to the ground or roof during installation.

- Solar Racking Connection: Solar racking is an important component to support solar panels, and the blind rivets are used to connect the metal components of the racking.

- Cable Fixing: In a solar system, cables are needed to connect solar panels, inverters and other components. Blind rivets can fix the cable clamps and brackets.

- Solar Inverter Mounting: Blind rivets are used to secure the inverter to the racking or support structure.

Blind Rivets are mainly used in the solar industry for solar panel mounting, racking connections, cable fixing and inverter installation. They provide reliable connections and stability to ensure proper functioning and safe performance of solar systems. The development of the solar industry has driven the widespread use of blind rivets in the renewable energy sector. If you want to know more about the application of blind rivets in the solar industry, you can visit our article “how to choose blind rivets for solar industry“.

Application of Blind Rivets for Boats Industry

Shipbuilding also requires the use of a large number of blind rivets. However, the shipbuilding industry has special requirements for blind rivets. Here are some common application scenarios.

- Steel Plate Connection: The structural members of a ship usually consist of multiple steel plates, and the blind rivets can firmly connect these plates together to provide a stable structure and ensure the overall strength of the ship’s hull.

- Ship Frame Connection: Ship frames are the backbone of the hull, core-pulling rivets can connect the frame members with steel plates to provide strong structural support and stability.

- Ship equipment installation: In shipbuilding, various equipment needs to be installed, such as piping, electrical equipment, deck equipment and so on. Blind rivets are used to secure equipment brackets and bases.

- Ship deck connection: The deck is the platform on the ship, which needs to be firmly connected with the hull structure. Blind rivets connect the deck plates to the hull structure, providing a strong deck structure to withstand the forces and vibrations associated with ship operations and the marine environment.

- Ship Interior Decoration: In the interior of a ship, there is a need to install a variety of decorative and interior components, such as wall panels, ceilings, and seats. Blind rivets are used to secure these decorative components.

Application of Blind Rivets for Construction Industry

Blind rivets are one of the most commonly used connecting elements in the construction field and are widely used in the installation process of building structures and finishes. Blind rivets provide reliable connections and stability, ensuring the structural strength and safety of the building.

- Metal Structural Connections: Whether it’s steel, aluminum or other metal structures, blind rivets can connect the components together.

- Curtain Wall Installation: Curtain wall is a non-load-bearing decorative system for building facades, and blind rivets are used to secure curtain wall components, such as aluminum alloy profiles, glass and panels, to ensure the stability and safety of the curtain wall.

- Window and door installation: Blind rivets are used to secure window and door frames and metal or wood components to ensure stability, sealing and safety.

- Roof and Roof Frame Connections: Blind rivets can fasten roof panels, roof frame members and metal connectors together.

- Wall connections: Blind rivets can connect wall members, steel plates, metal angle yards, etc. together to ensure the stability and load-bearing capacity of the wall.

Application of Blind Rivets for Furniture Industry

Blind Rivets are mainly used in the furniture industry for frame connections, component fixing, and decorative piece installation. They provide reliable connections that ensure structural stability and durability of furniture. Here are some common applications.

- Frame Joining: Whether it’s furniture such as chairs, sofas or beds, they all need strong frames to provide support and stability. Blind rivets can connect the wood or metal components of the frame.

- Component fastening: In chairs, blind rivets provide a reliable connection between the seat and back; in cabinets, blind rivets secure drawer slides to ensure smooth opening and closing.

- Installation of decorative parts: Furniture usually uses decorative parts to add beauty and attraction, such as decorative feet, armrests, metal decorations and so on. Blind rivets are used to fasten these decorative pieces to ensure that they are securely attached to the furniture.

- Sheet metal connections: Sheet metal is often used in the manufacture of furniture, such as wood panels, man-made boards, etc.. Blind rivets can join these panels together to provide a stable structure, such as joining the seat and back panels of a chair.

- Assembled Furniture: Blind rivets can be used to connect the assembled parts of furniture, such as connecting the wooden frame and support structure of furniture.

Secue Your Projects with Reilable Blind Rivets from Rivmate Rivet Systems

The Rivmate Rivet System has a wide selection of blind rivets to meet the needs of any application you may have. You can get a wide range of blind rivets made from high quality raw materials from our factory. The quality is strictly in accordance with international quality standards. Whether you are looking for blind rivets, rivet nuts or self clinch fasteners. We can provide you with a fastener solution system that will satisfy you.

Get in touch today and let our expert engineers provide you with the best blind rivet solution for your project.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met