How to Install Rivet Nuts: The Complete Guide

Rivet nuts are an important part of riveted fasteners and are widely used in automotive manufacturing, aerospace, electrical appliances, machinery manufacturing and other industries. So how to install the rivet nut? By reading this article, you will learn all the steps to properly install a rivet nut.

Table of Contents

What are Rivet Nuts?

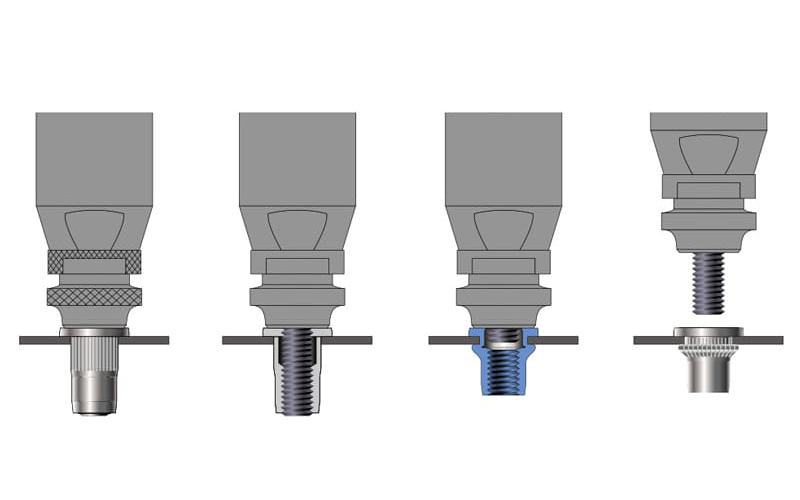

A rivet nut is a fastener used to join and secure materials. It consists of two parts:

- Internal thread

- Bottom disc

Rivet nuts can provide an attachment point for thin sheet materials and are used to provide a connection for bolts. Rivet nuts are commonly used in applications that require the creation of a strong threaded connection in thin plate or thin-walled materials, such as automobiles, airplanes, machinery and equipment, furniture, and more. They provide a convenient, reliable solution that makes it possible to make threaded connections where access from both sides is not possible.

Preparation Before Installing Rivet Nuts

- Drill bits for drilling holes

- Rivet nuts to be used

- Rivet nut tools that can be matched to the size of the rivet nut

- Materials to be riveted

How to Install Rivet Nuts?

1.Drilled Hole

Let’s demonstrate the installation process using a 1/8-inch rivet nut as an example.

In order to be able to drill a smooth hole, you need to have your electric drill gun ready. Insert the drill bit into the electric drill and then pneumatically drill the hole.

- Ensure that the drill is perpendicular to the material

- Drilling with a drill bit matched to the rivet nut

Insert Rivet Nut

In fact, installing a rivet nut is the same principle as installing a blind rivet. So now we just need to put the rivet nut prepared in advance onto the mandrel of the rivet nut tool. On the rivet nut tool, the mandrel is a rod, and you just need to put the internal threaded part of the rivet nut on the rod.

Then place the rivet nut into the hole drilled in advance in step one. (Note: the size of the pre-drilled hole should match the size of the rivet nut!)

Enable Rivet Nut Tool

Whether you are using a manual rivet nut tool or a pneumatic rivet nut tool for installation. You will need to start the tool to complete the process.

Here, I will describe the pneumatic rivet nut gun as an example.

Checking the Installation

It is important to ensure that the rivet nut is secure. Therefore, when performing any tests or adjustments, follow proper safety procedures and refer to the manufacturer’s recommendations and instructions. Consult a professional or engineer for more detailed guidance if required. Below are a few common ways to test the firmness of a rivet nut:

- Visual Inspection: It is possible to check with the naked eye that the rivet nut is installed correctly. Check that the threaded portion is completely in the bolt or screw and that the bottom disk is in tight contact with the surface of the material.

- Manual Test: Using an appropriate tool (e.g., wrench or torque wrench), attempt to gently rotate the rivet nut. If resistance is felt or the hold is tight, the nut is securely installed. Be sure not to over-turn as this may damage the threads or connection.

- Tension Test: For particularly critical connections, a suitable test device can be used to apply tension and check that the connection is able to withstand the required tension without loosening or detaching.

- Torque Test: Using a torque wrench or similar tool, apply the appropriate torque to the bolt or screw. Observe that the rivet nut resists the torque and remains secure.

- Vibration Test: For connections subjected to vibration or shock, apply vibration or shock force to the connection and observe for loosening or deformation.

Tips for Installing Rivet Nuts

- Select a mandrel that matches the size of the rivet nut to install the rivet nut. Ensure that the tool matches the size of the nut to avoid damage to the threads or connection.

- Before installing the rivet nut, make sure the surface of the joining material is clean and flat. Remove any dirt, grease or other obstructions to ensure that the rivet nut will make tight contact with the material.

- When rotating the rivet nut, apply even force to ensure that the threads enter the bolt or screw properly. Avoid applying too much or too little force, which could damage the connection or result in a weak installation. (Using a rivet nut gun can be a good solution to this problem)

Common Problems and Solutions for Installing Rivet Nuts

Bolt or Screw does not Go Into the Rivet Nut Correctly

Check the threads of the bolt or screw for damage, clean the threads and make sure the rivet nut is properly aligned.

Loose or Insecure Rivet Nut

Check to make sure the rivet nut is installed correctly and that the proper tightening force is applied with the proper tools and torque.

Damaged Threads

void over-tightening the rivet nut to avoid damaging the threads. If the threads are damaged, it may be necessary to replace the rivet nut or repair the threads.

Bottom Disc not Making Tight Contact with Material Surface

Check that the material surface is flat and make sure there are no obstructions preventing the bottom disc from making contact with the material. Consider using shims or other supplemental materials to fill the gap if needed.

Looking for Rivet Nut or Rivet Nut Tool? Rivmate can Help You !

Seeing this, you must have a deep understanding of how to install rivet nuts!

If you want to buy rivet nuts or rivet nut tools in bulk, then contact us!

Rivmate has a huge range of different types of rivet nuts and you can get all the rivet nuts you want at once at Rivmate! Whether they are made of carbon steel, stainless steel, iron, aluminum alloy or copper, you can source them all from Rivmate!

Trust me! You get the same quality rivet nuts and rivet nut tools for less money than you would pay locally! To learn more click to contact our engineers!