What is a Lockbolt Used For?

Table of Contents

What is a Lockbolt used for? Lockbolts are not fasteners designed for “ordinary connections.” Their core value lies in addressing structural connection challenges that demand high strength, high reliability, and low maintenance requirements. Understanding the true purpose of Lockbolts not only helps you avoid over-engineering or incorrect selection but also enhances installation efficiency and reduces long-term operational risks while ensuring structural safety. This article will explore typical application areas where Lockbolts are widely used, based on real-world engineering scenarios.

What is the Lockbolt?

Lockbolt rivet is specifically designed to provide a very strong and durable connection. They are often used in industrial and structural applications where high strength and durability are required. Examples include bridges, construction, heavy equipment and transportation vehicles etc. The unique design of Lockbolt rivets allows them to remain stable in high stress and high vibration environments without loosening.

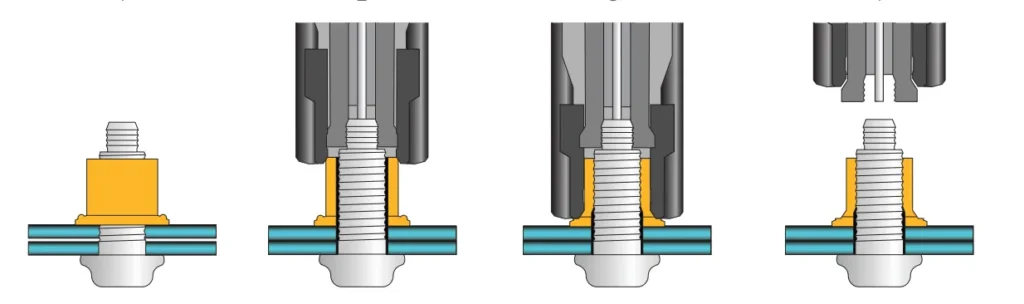

Lockbolt rivet is made up of a spike bar and collar. During installation, a pneumatic rivet gun is used to pull the spike bar, deforming the collar or mechanically locking it to tighten the material.

Lockbolt rivet provides very high shear and pull strength and is very easy to install for high volume use.

Lockbolt rivet is made up of a spike bar and collar. During installation, a pneumatic rivet gun is used to pull the spike bar, deforming the collar or mechanically locking it to tighten the material.

Lockbolt rivet provides very high shear and pull strength and is very easy to install for high volume use.

What is a Lockbolt Used For?

Lockbolt rivet acts as a high-strength mechanical fastener that provides a very strong and solid connection. They are often used in structural areas where ultra-high strength is required. Let’s take a look at the “what is a lockbolt used for”.

Applications of Lockbolt Rivets

Lockbolt rivets are suitable for heavy duty and high stress applications due to their extremely high shear and pullout forces. And lockbolt rivet has very high stability, even in high vibration environments. lockbolt rivet makes an indispensable fastener solution in modern engineering and manufacturing. Let’s take a look at some of the specific application scenarios for lockbolt.

Lockbolt for Bridge Construction

Any bridge needs to be safe and secure. lockbolt rivet can provide the tremendous loads and dynamic stresses that bridges require. That’s why a large number of lockbolt rivet are used in bridge connections, here are some common scenarios:

- Major structural connections

- Bridge deck fixing

- Bridge parapets and guards

- Bridge maintenance and rehabilitation

- Bridge extensions and modifications

Lockbolt rivet provides a high-strength, vibration-resistant, corrosion-resistant and long-lasting connection, benefits that make it a critical fastener for ensuring the safety and stability of bridge structures. By using the specialized lockbolt rivet tool, lockbolt rivet can perform a variety of connection tasks quickly and reliably, improving the efficiency and quality of bridge construction and maintenance.

Lockbolt for Building Structure

A secure building is connected by a variety of strong fasteners, and the Lockbolt rivet is one of those important fasteners. Below are the applications of lockbolt rivet in building structures:

- Steel frame connections

- Connection of roof and wall structures

- Connection of floor slabs and stair structures

- Installation of protection and safety devices

Lockbolt for Heavy Equipment and Machinery

Lockbolt rivet ensures the safe operation of heavy equipment and machinery in harsh conditions due to its excellent characteristics. Below are some specific applications of lockbolt rivet on heavy equipment and machinery:

- Connection of critical structures such as booms, buckets and undercarriages of excavators

- Connection of bulldozers’ fuselage and blade holders

- Connection of boom and base of cranes

- Connection of rollers and frames in road rollers

- Connection of mining truck body and chassis

- Connection of key parts of a crusher, such as jaws and frame

- Connection of combine harvester and tractor frames, frames and working parts

- Connections of frames and chassis of heavy trucks and transportation equipment

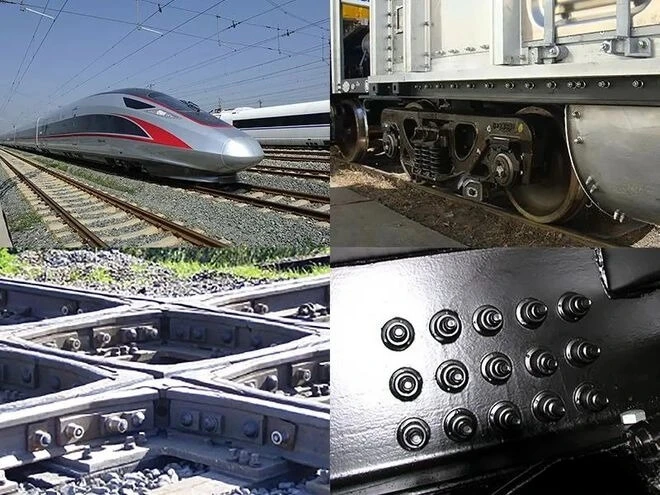

- Fixing of railroad carriages and rails

Lockbolt for Transportation Vehicles

Lockbolt is used in a wide range of transportation vehicle applications, including frame and chassis connections, trailer and semi-trailer connections, door and window frames, interiors and bulkheads, guards and safety devices, as well as compartment and cargo hold fastening. They provide high-strength, vibration-resistant, fatigue-resistant and long-lasting connections that ensure the safety and stability of vehicles when transporting heavy loads. With the use of specialized installation tools, lockbolt rivet can perform a wide range of joining tasks quickly and reliably, increasing vehicle productivity and maintenance efficiency.

Lockbolt for Aerospace

Aerospace is a very safety-conscious industry, and engineers use a number of high-strength fasteners, including lockbolt.

Used primarily in aircraft fuselage structures, wings and tails, engines and drivelines, hatches and covers, interiors and finishes, as well as maintenance and restoration work, Lockbolt provides aircraft with the high-strength, vibration-resistant, fatigue-resistant and long-lasting connections it needs. It ensures the safe operation of aircraft under high loads and stresses.

Why Use Lockbolts Instead of Bolts or Welding?

In engineering structural design, connection methods directly impact safety, reliability, and long-term costs. Lockbolt is not a simple replacement for ordinary bolts, but a mechanical locking system engineered for high vibration, high fatigue, and high consistency demands.

a. Vibration Resistance

Lockbolt employs a permanent mechanical locking structure rather than relying on thread friction for anti-loosening. During installation, the lock ring is pressed into the pin groove, creating an irreversible metal-to-metal interlock. This structure prevents self-loosening under sustained vibration and impact loads. In contrast, standard bolts primarily maintain preload through friction. In high-vibration environments, contact surfaces gradually undergo micro-slip, causing continuous preload decay. Industry testing consistently shows that traditional bolts experience clamping force decay of up to 30% or more under vibration conditions, whereas Lockbolt exhibits virtually no such degradation.

b. Clamp Force Retention

Conventional bolts derive clamping force from installation torque, but torque does not equate to actual clamping force. Variations in friction coefficients, lubrication conditions, and operational practices can cause significant fluctuations in clamping force. Lockbolt employs a break-off installation principle where the installation tool directly controls the tensile force. Clamping force is determined by the structure and equipment itself, not by human experience. Consequently, each installation achieves highly consistent clamping force. In engineering practice, Lockbolt typically delivers more stable and long-term clamping force retention, which is critical for structural rigidity and connection reliability.

c. Fatigue Life

Structural fatigue failure often originates at connection points rather than the base material itself. Cyclic stress accumulates rapidly when micro-movement or reduced clamping force exists at joints. Lockbolt eliminates stress concentration at thread roots while effectively preventing relative slippage between joints, resulting in more uniform stress distribution. Multiple fatigue comparison tests demonstrate that under identical load conditions, the fatigue life of Lockbolt connections is typically 2 to 5 times longer than that of standard bolted connections. This superior fatigue performance is a key reason for its widespread adoption in bridges, railway vehicles, and heavy equipment.

d. On-site Efficiency

From an on-site construction perspective, welding often entails higher time costs and safety risks, requiring power sources, gases, protective measures, and additional quality inspections. Conventional bolts typically necessitate double-sided operations and repeated torque verification. Lockbolt can usually be installed from a single side, with each installation point taking only 2 to 4 seconds and exhibiting an extremely low rework rate. In large-scale projects, this efficiency advantage significantly shortens construction cycles while reducing on-site management and labor costs.

e. Total Life Cycle Cost

Although Lockbolt’s per-unit procurement cost is typically higher than standard bolts, engineering decisions should focus not solely on initial price but on total life cycle cost. Lockbolt requires virtually no retightening during service, carries minimal risk of loosening, and substantially reduces maintenance and inspection costs. In high-vibration or high-safety-level applications, when considering installation efficiency, maintenance costs, and failure risks collectively, Lockbolt often proves the lower-overall-cost solution. This fundamental advantage is driving its gradual replacement of welded and traditional high-strength bolts.

Lockbolt vs Bolt vs Structural Rivet

| Comparison Criteria | Lockbolt | Standard Bolt | Structural Rivet |

|---|---|---|---|

| Shear / Tensile Strength | High. All-metal mechanical lock with stable clamp force. Predictable shear and tensile performance | Medium–High. Performance depends on preload and installation quality | Medium. Load mainly carried by the shank. Limited clamp force |

| Vibration Resistance | Excellent. Mechanical locking. No reliance on friction. Virtually no loosening | Poor. Preload loss common under high vibration | Good. No threads. Low risk of self-loosening |

| Removability | No. Permanent fastener | Yes. Can be repeatedly assembled and disassembled | No. Permanent fastener |

| Installation Consistency | Very high. Pin-tail break confirms correct installation | Low. Torque does not equal preload. Strongly affected by human factors | Moderate. Depends on process stability |

| Maintenance Requirement | Very low. No re-torque required | High. Periodic inspection and re-tightening needed | Low. Generally maintenance-free |

| Long-Term Cost (TCO) | Low. Higher initial cost, but minimal maintenance and rework | Medium–High. Low initial cost, but high maintenance over time | Medium. Low maintenance, but limited application range |

Lockbolt significantly outperforms standard bolts in vibration resistance, preload retention, and fatigue life, making it particularly suitable for high-vibration and safety-critical structures. Although the unit price is higher, maintenance and failure risks are substantially reduced during long-term operation, resulting in lower total lifecycle costs.

Standard bolts offer advantages in disassembly and lower initial costs, but suffer from pronounced preload decay in vibrating environments. Numerous engineering failures stem not from material degradation, but from bolt loosening.

Structural rivets occupy an intermediate position. They do not rely on threads, offering superior vibration resistance compared to standard bolts, but their clamping force and structural rigidity are limited. They are typically used in medium-load or thin-plate connection scenarios.

- Prioritize Lockbolt: High-vibration, high-fatigue, high-safety-grade structures

- Select Standard Bolts: Applications requiring frequent disassembly or low-vibration environments

- Choose Structural Rivets: Medium-load, simple structures requiring permanent, maintenance-free connections

Are Lockbolts Permanent?

Yes. Lockbolt rivet is considered a permanent connection. They are uniquely designed to provide a long-term, stable and strong mechanical connection that is not easily loosened or removed.

Lockbolt rivets are considered permanent connections for the following reasons:

- Non-removability: Once a lockbolt rivet has been successfully installed, removing it requires the use of destructive tools and methods such as drilling or cutting.

- Extremely high connection strength: lockbolt can provide extremely high shear and pull-out forces, which can ensure the stability and solidity of the connected parts in long-term use.

- Resistance to vibration and fatigue: Lockbolt can maintain its performance in high vibration and high stress environments and will not loosen or fail due to long-term use.

- Durability: Lockbolt has excellent corrosion and fatigue resistance, and can be used for a long time in harsh environments!

How to Choose the Right Lockbolt for Your Project?

In practical engineering applications, the correct selection of Lockbolt directly determines the reliability of the connection. Many failure cases stem not from product quality issues, but from unclear judgments during the selection phase.

① Total Material Thickness

The first step is not selecting the diameter, but confirming the total thickness of the components being joined. This includes all steel plates, shims, and structural layers. Lockbolts secure components by locking them in place via the retaining ring. Incorrect thickness assessment directly leads to failure to lock or insufficient clamping force. It is recommended to measure the actual thickness first, then work backward to determine the Grip Range, rather than selecting the model first.

② Diameter Selection

The Lockbolt diameter primarily determines shear and tensile resistance. Larger diameters offer higher load-bearing capacity but also increase costs and hole machining requirements. Common engineering guidelines include:

- Shear-dominant structures: Prioritize calculations based on shear loads

- Tensile or composite loads: Verify minimum tensile strength

- Avoid blindly increasing diameter when hole tolerances are insufficient

③ Grip Range

Grip Range is the most overlooked yet critical parameter in lockbolt selection. It denotes the material thickness range where the lockbolt can reliably secure. If thickness falls below the lower grip limit: clamping force is insufficient, leading to loose connections. If thickness exceeds the upper grip limit: the lock ring cannot fully form, posing a failure risk.

Actual thickness should fall within the middle of the Grip Range, not at the boundaries.

④ Material Selection (Carbon Steel / Alloy Steel / Stainless Steel)

Material determines strength, durability, and cost.

- Carbon Steel: Cost-effective, suitable for most structural components

- Alloy Steel: Higher strength, suitable for high-load and safety-critical applications

- Stainless Steel: Corrosion resistance prioritized, typically lower strength than alloy steel

The advantage of stainless steel Lockbolts lies in corrosion resistance, not ultimate strength. In high-load environments, stainless steel cannot simply replace alloy steel.

⑤ Tool Compatibility

Lockbolts are not “universal” fasteners. They must be used with specified tools. Verify the following:

- Does the tool support the required diameter?

- Does the pulling force meet material grade requirements?

- Is the pneumatic or hydraulic system stable?

Insufficient tool pulling force will result in inadequate clamping force even with the correct model, creating potential hazards.

FAQs-What is a Lockbolt Used For?

Q1. What is a lockbolt used for?

Lockbolts are used in high-vibration, high-fatigue, and safety-critical structures such as bridges, rail vehicles, heavy trucks, and construction machinery. Their primary function is to provide long-term stable clamping force, preventing connection loosening due to vibration. They are often used as an alternative to welding or traditional high-strength bolts.

Q2. Are lockbolts stronger than bolts?

In terms of material strength alone, both may be rated at the same level. However, in practical engineering applications, lockbolts are generally more reliable. This is because their clamping force remains stable and does not rely on thread friction, whereas conventional bolts may experience over 30% decay in preload under vibrating conditions.

Q3. Are lockbolts permanent?

Yes, lockbolts are permanent fasteners. Once installed, they cannot be disassembled without cutting and are therefore ideal for structures where loosening or maintenance is unacceptable.

Q4. Lockbolt vs Bolt vs Rivet (What are the differences?)

Lockbolts offer the strongest vibration resistance, stable clamping force, and lowest maintenance requirements. Standard bolts are removable with low initial cost but prone to loosening. Structural rivets lack threads, provide decent vibration resistance, but have limited clamping force and load capacity.

Q5. When should I use a lockbolt?

Lockbolts should be prioritized when structures endure prolonged vibration or impact loads, demand high fatigue life and safety standards, and require no subsequent retightening or maintenance. Their advantages lie in long-term reliability and total lifecycle cost, not individual unit price.

Order High Strength Lockbolt Rivet

Looking for a professional lockbolt supplier for your project? Contact Rivmate!

Rivmate can provide you with high-strength, corrosion-resistant and long-lasting lockbolts, and you can choose from a wide range of materials and specifications from Rivmate to meet the needs of your different projects.Rivmate has an experienced team of technicians who can provide professional selection advice and technical support!

The lockbolt rivet supplied by Rivmate meets the international quality standard, you can rest assured to use it!

Rivmate can provide you with a full range of solutions, understand contact Rivmate, order lockbolt rivet!

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met