What is A Speed Rivet? - Speed Rivet Technology

Table of Contents

What is a Speed Rivet? Do you want to know about speed rivets in detail before you buy it?This blog will provide you with the most comprehensive explanation. Let’s read it together.

What is A Speed Rivet?

Speed Rivet is a rivet type designed with rapid installation as its core objective, enabling significantly reduced riveting time and simplified processes while ensuring reliable connections. It typically achieves a less-step, less-operator-dependent installation through optimized structural design and forming methods.

Fundamentally, the distinction between Speed Rivet and traditional solid rivets or blind rivets lies not in material composition but in installation logic. Traditional solid rivets typically require dual-side operation and high operator skill. While blind rivets allow single-side installation, they often involve multi-step breaking or deformation processes. Speed Rivets, however, achieve stable connections faster through more direct forming mechanisms, reducing reliance on operator experience.

The term “Speed” does not imply a mere pursuit of velocity, but rather signifies overall installation efficiency gains. This encompasses fewer process steps, reduced single-point installation time, and enhanced consistency. This efficiency advantage is particularly pronounced in high-volume production or cycle-time-sensitive assembly environments, representing the core engineering value of Speed Rivets.

How Does a Speed Rivet Work?

Structural design prioritizes simplified forming

Speed Rivets typically consist of an optimized rivet body engineered to achieve rapid, stable plastic deformation under load. Compared to traditional rivets, they reduce reliance on complex deformation paths, streamlining the forming process.

Forming Principle Emphasizes “Single-Step Forming” Over Multi-Step Accumulation

Engineering-wise, Speed Rivets achieve clamping and locking through controlled deformation, eliminating the need for repeated hammering or staged breaking. Load is rapidly converted into stable clamping force during forming, establishing and securing the connection within a short timeframe.

Reduced installation time stems from streamlined process paths

The “speed” of Speed Rivet does not result from softer materials or lower strength, but from minimized operational steps and adjustment time. Eliminating repetitive positioning, correction, or confirmation of forming status significantly reduces total operation time per connection point—particularly evident in batch assembly.

Lower operator dependency through structural adaptability

Traditional riveting often relies on operator experience to judge adequate forming. Speed Rivet’s structural design makes the forming process insensitive to operator variation. Consistent connection results are achieved as long as basic process conditions are met, reducing human influence on quality.

Consistency takes precedence over ultimate strength

From an engineering perspective, Speed Rivet prioritizes connection consistency and predictability over pursuing maximum load-bearing capacity. This focus makes it highly suitable for production environments where cycle time sensitivity and stringent quality consistency are paramount.

Types of Speed Rivets

Speed rivets come in several different types, depending on the actual requirements of your project. The following are common types of speed rivets:

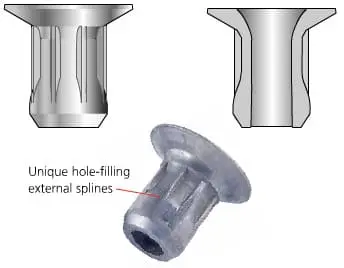

a. BRV Speed Rivets

BRV Speed rivets have a unique bulbous rear end. The shortening of the ball end during installation ensures the strength of the connection. And its large head-shaped tail provides a large carrying area for soft materials.

BRV Speed rivets are also characterized by their ability to fill irregular holes. Most importantly, of course, speed rivets cost less than welding or other rivets when working in the field!

b. CBT Speed Rivets

CBT Speed rivets date back to the 1930s. It is available in a variety of finishes including galvanized, brass and other options.

CBT Speed rivets have a consistent clamping force that reduces damage to soft or brittle materials. For this reason, it is often used in household appliances and lightweight manufacturing.

c. NeoSpeed Speed Rivets

Neospeed speed rivets are the strongest and most versatile fastening system on the market, according to data presented by Avdel Neospeed.Neospeed speed rivets provide enough strength and installation speed that it can be installed up to four times faster than traditional threads or rivets!

Neospeed speed rivets have a unique rivet design. This design allows for increased clamping force and a wide riveting range. It provides multi-grip capability and can accommodate materials of varying thicknesses.

This type of speed rivets is half the weight of traditional rivets, effectively reducing the overall weight of the equipment. Reduces energy consumption during operation.

Advantages of Speed Rivets?

Why was the speed rivet invented? Because it has many advantages that other riveted fasteners do not have. Let’s read on.

① No Need to Reload Rivets

When engineers install speed rivets, they preload the speed rivet gun with a large number of speed rivets, thus eliminating the need to repeatedly load rivets when installing industrial equipment. Using speed rivets for the same project can save a great deal of time, especially if the manufacturer is doing mass production.

② Very Fast Installation

The best thing about Speed rivets is that it installs very quickly. And it’s perfect for high volume installations.

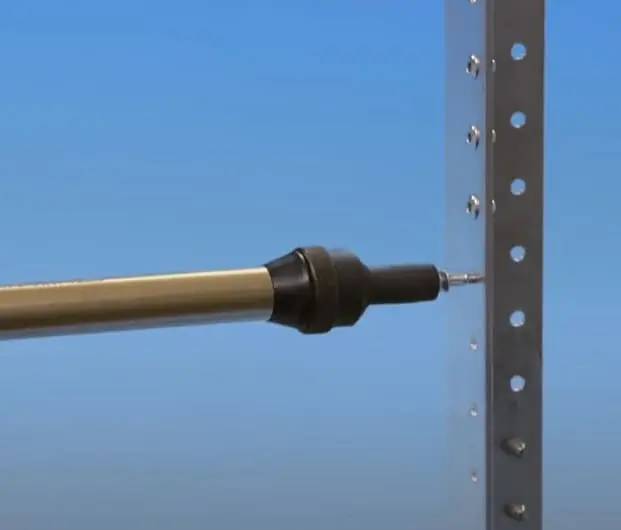

Speed rivets can be installed on factory automated assembly lines using automatic riveting machines. Trust me, you can save up to two-thirds of the time!

Let’s enjoy a quick install of the speed rivet! Let’s appreciate how time-saving the following speed rivet installations are.

③ Cost-effective

In actual production, speed rivets cost less than welded or blind rivets. Both the cost of time and the economic cost of the rivets themselves. This can be a huge saving to your budget!

④ Smooth Exterior

Speed rivets have a very flat surface with no bumps after the installation is complete. This provides a very aesthetic appearance. Especially suitable for applications where a smooth surface is required!

For example, speed rivet is used extensively in the plastic housings and heat sinks of electronic devices and in the metal housings and internal frames of household appliances.

Speed Rivet vs Traditional Rivets

Speed Rivet vs Traditional Rivets: Engineering Comparison Table

| Comparison Criteria | Speed Rivet | Traditional Rivets |

|---|---|---|

| Installation Speed | Fast. Fewer steps, short installation time per point | Slower. Typically requires multiple forming steps |

| Operational Complexity | Low. More straightforward installation process | Higher. Relies more on operator timing and judgment |

| Dependence on Tools & Labor | Lower. Less dependent on operator experience | Higher. Requires proper tooling and skilled operators |

| Joint Consistency | High. Stable and predictable forming results | Medium–High. More influenced by human factors |

| Applicable Material Thickness | Defined range, optimized for standardized thickness | More flexible, suitable for a wider thickness range |

| Maintenance & Rework Risk | Low. High consistency reduces rework rates | Low, but improper installation may require rework |

Differences in Installation Speed

The primary advantage of Speed Rivets lies in the manufacturing process. By reducing forming steps and setup time, it significantly shortens the installation time per rivet. While traditional rivets are mature and reliable, they typically require more operational steps during forming, resulting in a slower overall cycle time.

Operational Complexity and Personnel Dependency

The quality of traditional rivets relies to some extent on the operator’s judgment of the forming state. Speed Rivet’s structural design makes the forming process more “adaptive.” This reduces dependence on operator experience, making it better suited for production environments with high personnel turnover or limited training cycles.

Connection Consistency

In high-volume assembly, consistency often outweighs single-point strength. Speed Rivet’s standardized forming logic facilitates consistent connection quality across shifts and operators. While traditional rivets remain reliable with sufficient experience, they exhibit higher variability.

Differences in Applicable Material Thickness

Traditional rivets offer greater flexibility in material thickness adaptation, making them suitable for complex structures or applications with significant thickness variations. Speed Rivets are typically optimized for specific thickness ranges, making them better suited for standardized designs and repetitive assembly.

Maintenance and Rework Risk

Both are permanent fasteners requiring minimal maintenance under normal design conditions. Speed Rivets carry lower rework risk due to their high installation consistency; traditional rivets may require rework or re-riveting when installation deviations are significant.

Where Are Speed Rivets Commonly Used?

Speed Rivets are used in a variety of industrial environments due to their unique benefits. A look at some of the applications for speed rivets:

1.Speed Rivets for Domestic Electric Appliance

The use of household appliances is very high. It is believed that there are a lot of appliances in everyone’s home, so keeping each appliance fully assembled requires a lasting solution.Speed rivets are widely used in household appliances to connect a variety of different housings for assembly. Although traditional blind rives can also complete the process, speed rivets are faster.

In addition, speed rivets weigh half or less than blind rivets. This reduces the overall weight of the appliance. It helps the customer to make different visits to the appliance and enhances the happiness of the customer.

2.Speed Rivets for Lightweight Construction

In the industrial sector, in addition to heavy equipment, there are also lightweight structures. Lightweight construction needs to ensure that the overall weight of the equipment does not feel heavy.

Speed rivets manufacturers can provide lightweight designs. Maintaining reliable strength while still making your equipment lighter. This technology improves structural integrity by not damaging materials.

3.Speed Rivets for Electronic Equipment

Electronic devices often have high weight requirements. So it is not possible to use fasteners that are inherently heavy, and Speed rivet brings the solution.

Speed rivets reduce the cost of electronic equipment while reducing its weight. This is very helpful in selling electronic equipment.

FAQs About Speed Rivets

Q1. What is a speed rivet used for?

Speed Rivets are primarily used in high-volume, cycle-time-sensitive assembly scenarios. Commonly found in sheet metal structures, industrial equipment, and production lines requiring high consistency, their core value lies in reducing installation time and minimizing human operational variation.

Q2. Are speed rivets stronger than standard rivets?

Not necessarily. Speed Rivets’ advantage lies not in ultimate strength, but in installation consistency and efficiency. Under identical design conditions, traditional rivets can achieve comparable or even higher load-bearing capacity. However, Speed Rivets more reliably deliver consistent performance.

Q3. Are Speed Rivets permanent?

Yes. Speed Rivets are permanent fasteners. Once installed, they cannot be removed without destruction. This makes them suitable for structures where loosening is unacceptable.

Q4. Do Speed Rivets require special tools?

Typically, installation tools matching the rivet’s structure are needed, though tool operation is relatively straightforward. Compared to traditional riveting, Speed Rivets rely less on operator skill and experience, making them better suited for standardized production.

Q5. Speed Rivet vs Blind Rivet

Blind rivets offer the advantage of single-side installation, making them suitable for structures where the back side is inaccessible. Speed Rivets excel in installation cycle time and consistency, making them more suitable for repetitive, high-efficiency assembly. They serve different application scenarios and are not mutually substitutable.

Increase Production Efficiency with Rivmate Speed Rivets

Want to improve the efficiency of production? Rivmate Speed Rivets is one of the best speed rivets solution providers. Purchase speed rivets and apply them to your project for the fastest productivity.

Contact us today for high quality speed rivets solutions for your assembly needs. Our engineers will provide the best solution for your project.

reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met