Are Rivets Stronger Than Screws?

Table of Contents

Are Rivets Stronger Than Screws? Do you know which is stronger, rivet or screw? Do you know what applications they are used in respectively? With this blog, you will learn all about it.

Are Rivets Stronger Than Screws?

It depends on how strength is defined.

When comparing shear strength, rivets typically hold the advantage. Rivets feature a smooth shaft structure where shear loads are directly borne by the shaft body, ensuring uniform stress distribution without the issue of threaded sections weakening the cross-section. Under high shear conditions, rivets often exhibit more stable actual load-bearing capacity.

When comparing tensile strength, screws generally prove stronger. Screws can withstand axial tensile forces through preload, and high-strength bolts offer clear advantages under pure tensile conditions. However, this advantage relies on proper installation and sustained preload.

When comparing vibration resistance, rivets are generally more reliable. Rivets provide a permanent connection independent of thread friction, preventing gradual loosening due to vibration. Under sustained vibration or cyclic loading, screw preload can decay by over 30%, whereas rivets carry virtually no risk of self-loosening.

In high-shear and high-vibration applications, rivets are generally more reliable than screws; in primarily tensile scenarios requiring disassembly, screws are more suitable.

Strength of Rivets and Screws

The strength of rivets and screws is mainly composed of the following strength types:

- Shear strength

- Tensile strength

- Fatigue strength

So what do these three types of strength mean?

Shear Strength

Shear strength refers to a fastener’s ability to resist lateral loads. In this regard, rivets typically exhibit more consistent performance. Rivets feature a smooth shaft structure where shear forces act directly across the entire cross-section. Stress distribution remains uniform, eliminating the issue of threading reducing the effective cross-sectional area. In contrast, screws under shear loads often rely on the root of the threads for support—precisely where stress concentration is most pronounced. In high-shear applications, rivets exhibit more predictable failure modes, which is why they are widely adopted in structural connections.

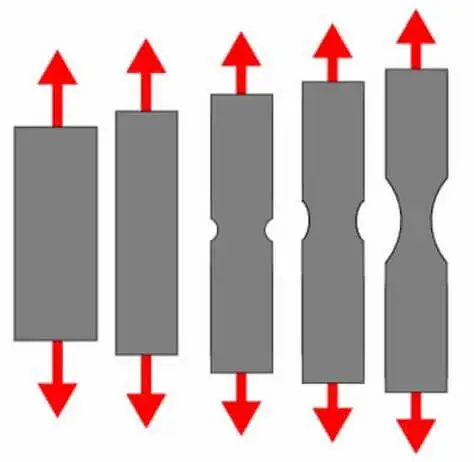

Tensile Strength

Tensile strength measures a fastener’s ability to resist axial pulling forces. Screws typically excel in this dimension because they can convert external tensile loads into frictional loads through preload. High-strength bolts exhibit outstanding tensile performance under ideal installation conditions. However, it is important to note that this advantage is highly dependent on proper torque control and long-term preload retention. Once preload diminishes, the tensile performance of screws degrades significantly, a scenario not uncommon in vibrating environments.

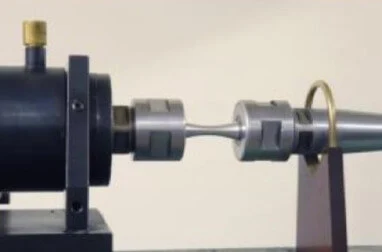

Vibration & Fatigue Life

In real-world applications, vibration and cyclic loads often prove more destructive than static loads. Screw connections rely on thread friction to maintain preload. Under prolonged vibration, preload may gradually decrease, potentially triggering fretting and fatigue cracks. Rivets, being permanent fasteners, do not depend on preload and are immune to thread loosening. In high-vibration environments, rivets typically exhibit more stable fatigue life—a key reason why riveted structures are widely adopted in aerospace, rail transportation, and heavy equipment applications.

Rivets vs Screws: Engineering Comparison

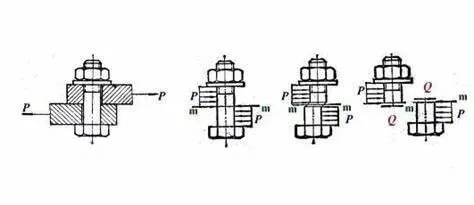

Differences in Shear Load-Bearing Mechanisms

Rivets primarily bear shear loads directly through the smooth shaft body. This simple force path ensures uniform shear distribution across the entire cross-section, resulting in stable behavior. Screws, however, often rely on their threaded regions to bear shear forces. The thread root—the narrowest section—becomes the highest stress point. Under high shear loads or cyclic shear conditions, rivets’ load-bearing mechanism more closely aligns with ideal structural models, resulting in more predictable engineering performance.

Stress Concentration in Threaded vs. Smooth Shank Structures

Threaded structures inherently exhibit stress concentration issues. Even in high-strength screws, the thread root remains the most susceptible location for fatigue cracking. Rivets feature a smooth cylindrical structure with continuous stress distribution and no geometric discontinuities. Under cyclic loading conditions, this structural difference directly impacts fatigue life, making rivets a long-standing choice in aerospace and rail transportation.

Dependence on Preload

The engineering performance of screw connections heavily relies on preload. Theoretical strength assumptions hold only when preload is correctly applied and maintained long-term. However, in actual operating conditions, variations in friction coefficients, installation deviations, and vibration all cause preload decay. Rivets do not depend on preload to maintain connection strength; instead, they achieve load-bearing through geometric locking formed during installation. This characteristic makes rivets insensitive to human factors and environmental changes after installation.

Risk of Loosening Under Long-Term Loading

Under prolonged vibration or cyclic loading, screw connections may experience micro-motion, leading to reduced preload and gradual loosening. This process is typically gradual and difficult to detect in its early stages. As a permanent fastener, rivets do not suffer from thread rotation or preload decay issues. Their failure usually manifests as material failure rather than connection loosening. From an engineering safety perspective, this failure mode is more direct and easier to control during the design phase.

Why Are Rivets Used in Aircraft, Rail, and Heavy Equipment?

In high-reliability industries, the choice of fastening methods is not determined by “ease of disassembly,” but rather by long-term safety, predictability of failure, and system reliability. The long-term, widespread use of rivets in aerospace, rail, and heavy equipment sectors is not a matter of tradition or inertia, but an industry consensus formed through decades of engineering validation.

Why Rivets Remain Pervasive in Aerospace

In aerospace structures, loads primarily involve shear and cyclic fatigue rather than single static tension. The smooth shaft design of rivets evenly distributes shear forces, eliminating stress concentration issues associated with threads. In fuselages and wings, connection points endure millions of load cycles where even minor loosening rapidly propagates into fatigue cracks. Rivets provide permanent, preload-independent fastening without vibration-induced loosening risks—exactly meeting aerospace structures’ demands for long-term stability and predictable failure modes.

Why Railways and Heavy Equipment Avoid Threaded Connections

Rail vehicles and heavy equipment operate continuously under high vibration, high impact, and complex loading conditions. While threaded connections exhibit high strength under static conditions, their engineering performance heavily relies on maintaining preload. Under continuous vibration, preload decay is nearly inevitable, necessitating frequent inspections and retightening. Rivets, however, do not rely on friction or torque. Once installed, the connection remains stable and does not gradually loosen due to vibration. This is a key reason why the railway industry prefers riveting or similar permanent mechanical locking methods.

Why “Non-Removable” is an Advantage

In high-reliability systems, disassembly capability isn’t necessarily an advantage. Conversely, non-disassembly ensures the connection state remains consistent throughout the entire service life, unaffected by human error or maintenance mistakes. Permanent riveted connections reduce points of human intervention, lowering the risk of maintenance errors. From a systems engineering perspective, this design enhances overall safety levels and simplifies long-term maintenance strategies.

Common Misconceptions About Screws vs Rivets

In fastener selection, many decisions stem not from engineering calculations but from experiential intuition. The following common misconceptions about screws and rivets are widespread in real-world projects and frequently lead to incorrect choices.

Misconception 1: “Tighter Means Stronger”

Many assume that tightening a screw sufficiently will inevitably strengthen the joint. This assumption is theoretically flawed. A screw’s strength depends on effective preload, not the tightening action itself. Over-tightening can cause thread yielding, screw elongation, or even premature fatigue. Additionally, in vibrating environments, preload may degrade over time despite high initial torque. In contrast, rivets do not rely on torque and eliminate the “over-tightening or under-tightening” dilemma, maintaining a stable connection state after installation.

Misconception 2: “High-Strength Screws Are Always More Reliable”

High-strength screws indeed possess greater material strength, but material strength does not equate to system reliability. In practical engineering, the reliability of bolted connections heavily depends on installation quality, friction coefficients, and long-term preload retention. Once preload diminishes, high-strength screws can also suffer from micro-movement, loosening, and fatigue issues. While rivets may not necessarily offer higher material strength, their load-bearing mechanism is simpler, failure modes are predictable, and they often demonstrate higher overall reliability in conditions dominated by shear and vibration.

When Should You Use Rivets Instead of Screws?

Rivets vs Screws: Fastener Selection Quick Guide

| Engineering Condition | Preferred Choice | Key Reason |

|---|---|---|

| High shear loads | Rivets | Load carried by full shank, uniform stress distribution |

| Continuous vibration / impact | Rivets | No reliance on preload, no self-loosening |

| No loosening allowed | Rivets | Permanent joint, long-term stability |

| Maintenance cost sensitive | Rivets | Minimal inspection or re-tightening required |

| High consistency in mass production | Rivets | Standardized installation, repeatable results |

| Frequent disassembly required | Screws | Reusable and removable fastener |

a. High Shear Load Scenarios

When connections primarily endure lateral shear forces, rivets typically offer greater reliability. Rivets directly bear shear loads through their solid shank, featuring a clear stress path without the cross-sectional weakening issues inherent at thread roots. In heavy-duty structures and shear-dominant connections, this load-bearing mechanism more closely aligns with ideal engineering models.

b. Continuous Vibration or Impact Environments

Under prolonged vibration, screw performance heavily relies on maintaining preload, which inevitably degrades over time. Rivets do not depend on friction or torque, preventing gradual loosening due to vibration after installation. This makes them more stable in applications like rail transportation and construction machinery.

c. Structures where loosening is design-prohibited

In safety-critical structures, “loosening” itself constitutes failure. Rivets provide a permanent connection whose integrity remains consistent throughout the entire service life, unaffected by maintenance, environmental factors, or human intervention. This certainty is the fundamental reason riveting is prioritized in many high-reliability industries.

d. Sensitivity to Maintenance Costs and Downtime Risks

Screws typically require periodic inspection and retightening, entailing long-term labor costs and potential downtime risks. Rivets, when properly designed and installed, require virtually no subsequent maintenance. For structures that are difficult to access or have high maintenance costs, riveting offers greater advantages in total lifecycle cost.

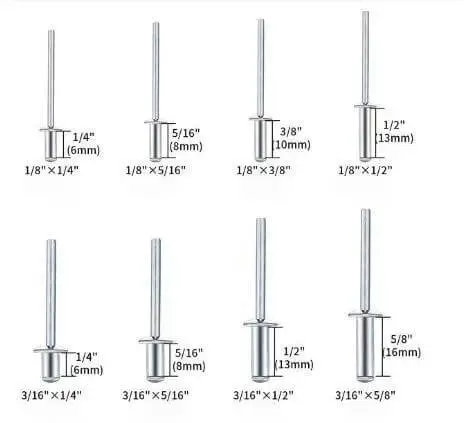

e. High Consistency Requirements in Mass Production

In high-volume assembly, the actual performance of screw connections is susceptible to torque deviations and operator variations. The riveting process is standardized, with visually verifiable results, making it easier to achieve stable, consistent connection quality on production lines.

FAQs About Rivets vs Screws

Q1. Are rivets stronger than screws in shear?

Generally yes. In applications where shear loads dominate, rivets offer greater reliability. Rivets bear shear forces through their entire shank, distributing stress uniformly. In contrast, screws often experience shear failure at the root of the threads, where stress concentration is more pronounced.

Q2. Are screws better for tensile loads?

Yes. Screws are generally more suitable for applications where tensile forces are predominant. Screws can effectively withstand axial tensile forces through preload, provided they are installed correctly and the preload is maintained over time.

Q3. Are rivets permanent?

Yes. Rivets are permanent fasteners that cannot be disassembled normally after installation; they can only be removed by cutting or destructive means. This characteristic makes them highly suitable for structures where loosening is unacceptable.

Q4. Can rivets replace screws?

In many cases, yes—especially in applications involving high shear, high vibration, and low maintenance requirements. However, if the structure requires frequent disassembly or adjustment, screws remain the more suitable choice.

Q5. Why not just use welding?

Welding introduces a heat-affected zone, alters material properties, and demands high standards for construction quality and operating conditions. In contrast, rivets are cold-formed fasteners that offer greater consistency in quality and easier risk control in both field applications and mass production.

Engineering Insight from Rivmate

Rivmate specializes in riveting solutions not because rivets are “superior,” but because we consistently encounter engineering scenarios demanding high shear resistance, high vibration tolerance, and high reliability. In these applications, the stability, predictability, and full-lifecycle performance of the connection far outweigh any single strength metric.

If you’re evaluating whether rivets suit a project or seeking a more rational balance between safety, maintenance costs, and production consistency, the right decision often stems from engineering logic, not gut instinct. Understanding the fundamental differences between connection methods is itself the first step in mitigating risk.

At Rivmate, our goal isn’t to promote a specific fastener, but to help you choose the right connection method. Contact us now:

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met