Table of Contents

Are Rivets Stronger Than Screws? Do you know which is stronger, rivet or screw? Do you know what applications they are used in respectively? With this blog, you will learn all about it.

Table of Contents

Strength of Rivets and Screws

The strength of rivets and screws is mainly composed of the following strength types:

- Shear strength

- Tensile strength

- Fatigue strength

So what do these three types of strength mean?

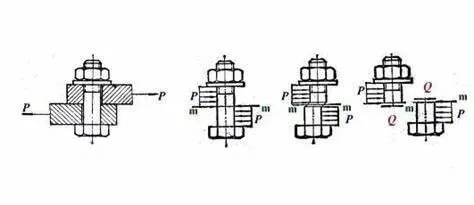

Shear Strength

Shear strength is defined as the maximum shear stress that a material can withstand before it breaks in shear. It is also the ability of a material to resist damage under shear. It measures the ability of a material to withstand a force parallel to its cross-section without damage. Shear strength is particularly important in mechanical connections because many connections (e.g., rivets, screws, etc.) are subjected to shear forces.

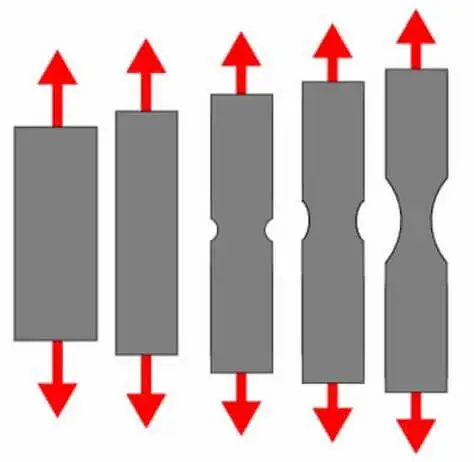

Tensile Strength

Tensile Strength (Tensile Strength) is the ability of a material to resist breaking under tensile force. It measures the maximum stress that the material can withstand before being stretched to fracture. Tensile strength is one of the important indicators for evaluating the mechanical properties of materials. Tensile strength has a wide range of applications in mechanical and structural engineering, building materials, and manufacturing and processing, ensuring the safety and reliability of materials and structures.

Fatigue Strength

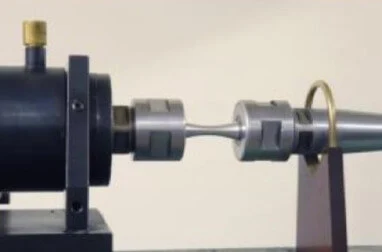

Fatigue strength is usually determined by fatigue testing. In this test, a material specimen is repeatedly loaded under a specific cyclic stress until the specimen breaks. Fatigue strength is generally expressed as the maximum value of stress at which a material will not break within a certain number of cycles (e.g. 10^6).

Fatigue Strength is the ability of a material to resist fatigue damage under cyclic stress. It is a measure of the maximum stress that a material can withstand without fatigue rupture under repeated loading and unloading conditions. Fatigue Strength is commonly used to predict the durability of materials in long-term use, especially in mechanical and structural applications.

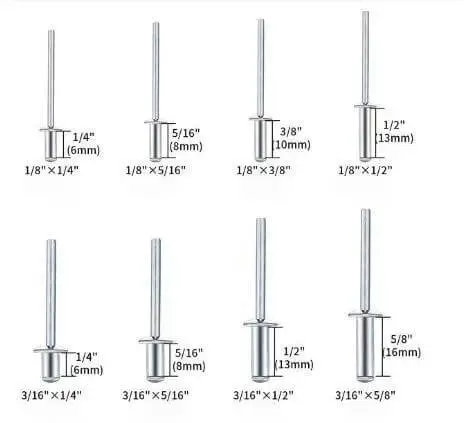

Strength of Blind Rivets

There are many types of rivets, including standard blind rivets, structural blind rivets and lockbolts, all of which have excellent shear, tensile and fatigue strengths. Of these, structural rivets and lockbolt have particularly high shear and tensile strengths. They are ideally suited for joining in high stress environments.

Because of their excellent tensile and shear strengths, high-strength structural rivets and lockbolt are widely used in structural installations for connecting automotive body panels and aircraft skins. At the same time, the excellent fatigue strength of the Blind Rivet ensures that it can maintain the stability of the connection under repeated pressure changes.

Of course, the strength of a blind rivet is not static. It will vary depending on the rivet material, the size of the rivet, whether or not it is properly installed, and the size of the hole.

Strength of Screws

Screws have relatively moderate shear strength. Although they are not as strong as rivets in terms of transverse forces, certain specially designed structural screws are available with enhanced shear strength.

Screws excel in tensile strength, which is greater than most rivets. It is ideally suited to applications that require a tight bond between materials.

However, in terms of fatigue strength, screws are not as good as rivets. Although they can withstand cyclic loading, they require a specific design to increase their fatigue strength.

What is Stronger, A Rivet or A Screw?

Rivets and screws each have their own benefits and application scenarios, and their sturdiness depends on the specific usage environment and connection requirements. Rivets are considered more robust in many situations where high strength and reliability are required, but screws have irreplaceable advantages in situations where frequent maintenance and adjustments are needed.

Blind rivets have many advantages. These include a permanent connection, good resistance to vibration, the ability to apply a uniform force to the material, and suitability for connecting a wide range of materials.

Because of these advantages, blind rivets are widely used in the assembly and connection of aircraft structures, which can provide a high-strength and long-term stable connection. Electric car Tesla and other car manufacturers also use a large number of core-pull rivets to connect body panels and frames, which can ensure the stability of the vehicle in a high-stress environment.

The robustness of the blind rivets is outstanding. It offers high shear and pullout forces, especially with high strength structural rivets and lockbolts, which provide extremely high shear and pullout forces and are ideal for use in high load and high stress environments.

The durability of blind rivets is also very good. In high vibration environments, blind rivets remain stable, making them ideal for long-term use.

Screw has a very good removability and can be installed and removed repeatedly. It is also very easy to install and can be used in any environment.

Screw is widely used in equipment that requires regular maintenance or parts replacement, such as household appliances and electronic equipment.

Screw provides a fairly high tensile strength and is suitable for connections subjected to axial tension.Screw has a higher tensile strength than some rivet.

Rivet vs Screw

| Comparison Item | Rivets | Screws |

| Connection Type | Permanent Connection | Removable Connection |

| Installation Tools | Specialized tools (e.g., hydraulic rivet gun, pneumatic rivet gun, manual rivet gun) | Common tools (e.g., screwdriver, electric screwdriver) |

| Shear Strength | High (especially structural rivets and lockbolts) | Moderate (suitable for axial tensile connections) |

| Tensile Strength | High (structural rivets and lockbolts) | High (especially suitable for axial tensile loads) |

| Vibration Resistance | High, not easily loosened | Moderate, may require anti-loosening measures (e.g., thread locker) |

| Multi-material Connection | Excellent (e.g., SPR rivets can connect aluminum and steel, avoiding galvanic corrosion) | Fair (suitable for similar or close materials) |

| Ease of Installation | Moderate (requires specialized tools but allows quick and efficient installation) | High (requires no specialized tools, suitable for various environments) |

| Maintenance and Replacement | Difficult (requires destructive methods for removal, not reusable) | Easy (can be removed and reinstalled, suitable for regular maintenance or replacement) |

| Flexibility | Low (difficult to adjust or reposition once installed) | High (easy to adjust and reposition) |

| Corrosion Resistance | High (using aluminum or stainless steel rivets, suitable for harsh environments) | Depends on material and coating (e.g., galvanized screws have good corrosion resistance) |

| Application Scenarios | Aerospace, automotive manufacturing, heavy machinery, structural buildings, body panels, chassis protection panels | Electronic devices, construction, woodworking, home appliances, equipment requiring regular maintenance |

| Aesthetic Quality | High (flush head after installation, does not affect appearance) | Fair (screw heads may protrude, additional treatment may be needed for aesthetics) |

| Installation Cost | High (specialized tools and equipment cost more but can increase production efficiency) | Low (common tools cost less, suitable for small-scale and repair use) |

| Connection Strength | High (provides high shear and tensile strength, suitable for high-stress and heavy-load applications) | High (provides high tensile strength, suitable for axial tensile load applications) |

Selection Recommendations

- Rivets: Suitable for applications requiring permanent, high-strength, vibration-resistant, and durable connections, such as aerospace, automotive manufacturing, heavy machinery, and structural buildings.

- Screws: Suitable for applications requiring removable, flexible, easy-to-maintain, and adjustable connections, such as electronic devices, construction, woodworking, and home appliances.

This article explains the comparison and difference between rivets and screws in terms of strength. If you want to know more about rivet vs screw, please read my other article.

Get High Strength Blind Rivet at the Best Price From Rivmate Rivet

Rivmate provides high quality blind rivet solutions. We are one of the leading pop rivet manufacturers in China, offering a wide range of project rivet fastener solutions for you to choose from.

Our products are not only varied but also of high quality. We provide customers and partners with thin sheet riveting solutions that fit their budgets.

We offer a wide variety of blind rivet and rivet nut.So, if you are looking for the best rivet solution for your project, feel free to contact us. We will get back to you as soon as possible.