Table of Contents

For those who are new to rivets, blind rivet construction can be a bit esoteric. But understanding blind rivet construction is essential if you want to better choose the right blind rivets for your business.

Therefore, this guide will introduce you to the four parts that make up blind rivet construction and what they do.

Table of Contents

Basic Components of Blind Rivet Construction

Blind rivets provide an excellent permanent solution for one-sided connections. It forms a stable joint primarily through the interaction of the rivet body and head flange.

The Blind Rivet consists of the following four parts:

- rivet body: The critical part that forms the expansion.

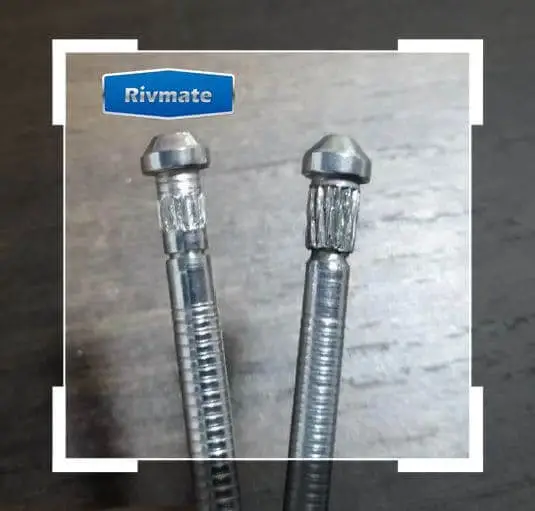

- rivet mandrel: The core of the blind rivet. The head is designed to be serrated or with a break neck groove with a shortening ring.

- Head Flange: The critical part that creates the clamping force.

- Rivet Material Head: The part that causes the rivet body to deform.

The Role of Blind Rivet Body

The Rivet body is the core structural part of the rivet. It provides several important functions:

- Provide mechanical connection and fixation

- Transmitting and carrying loads

- Adapt to different materials and environmental requirements

- Optimize installation and aesthetics

Nail bodies are used to securely fasten two or more components together by inserting them into holes in the connected parts and undergoing deformation (e.g. expansion, compression, or double-drum deformation) during installation. This deformation may be achieved by cold riveting (less than 8 mm) or hot riveting (greater than 8 mm). For example, the body of a blind rivet expands into a drum shape under the action of a rivet gun, clamping the material and distributing the pressure.

The rivet body is available in a variety of materials to suit different applications.

- Aluminum rivet body: lightweight and rust-resistant, suitable for electronic equipment or automotive components.

- Stainless steel rivet body: corrosion-resistant, suitable for harsh environments such as ships and chemical equipment.

- Steel rivet body: suitable for general applications.

To learn more about rivet body, read this article “The Ultimate Guide to Rivet Body ”.

Do You Have Any Questions?

Let Us Solve Your Problem

The Role of Blind Rivet Mandrel

Blind rivet mandrel is always used throughout the riveting process. The specific functions are as follows:

- To drive the rivet body to expand and form the rivet joint

- Provide shear strength

- Controls core breakage

- Adapts to the needs of different working conditions

When the core of the nail is pulled outward by a special tool (e.g. rivet gun), its head squeezes the end of the rivet body, forcing the body to expand and deform, thus filling and locking the hole in the workpiece and realizing one-sided riveting. This process eliminates the need for double-sided operation and is particularly suitable for applications where space is limited.

Structural rivets (such as monobolt blind rivets) have a core that is permanently locked into the rivet body after riveting, further enhancing the stability and shear strength of the joint.

The Role of Blind Rivet Mandrel Head

In the process of using, the mandrel head of Blind rivet mainly undertakes the following roles:

- Transmission of tension: During installation, the nail core head is pulled by a special tool to make the nail body expand and fit the workpiece to form a fastening effect.

- Adapt to unilateral operation: Since blind rivets are often used in areas that cannot be accessed from the back (e.g., temporary repair of aircraft skins), the design of the mandrel head allows installation to be accomplished from only one side, simplifying the process.

The Role of Blind Rivet Head Flange

The Blind rivet head flange plays the following key roles in installation and function:

- Forms a permanent connection with the rivet body.

- Adapts to project needs.

Blind rivet head flange generally comes in three types: 1. dome head 2. countersunk head 3. large flange head. you need to choose the right rivet head for your project.

- Dome head: Suitable for general use needs and is the most widely used type.

- Countersunk head: suitable for applications that require high surface flatness. With countersunk head blind rivets, countersunk holes need to be drilled in advance on the surface of the sheet.

- Large flange head: suitable for riveting brittle and soft materials, Large flange head can be well apportioned when riveting applications, to protect the brittle and soft materials from damage.

Do You Have Any Questions?

Let Us Solve Your Problem

What is the Structural Difference Between Structural Blind Rivets and Standard Blind Rivets?

1. Rivet Mandrel locking mechanism

- Structural Blind Rivets: The core of the nail is securely locked into the rivet body by a mechanical locking device after the riveting is completed and will not come loose. This design ensures a stable connection through mandrel retention load and is suitable for high vibration or high load environments.

- Standard Blind Rivet: Although the nail core is retained in the rivet body, but without the use of mechanical locking structure, relying only on the friction of the rivet body after expansion to fix, long-term use or vibration may be loosened.

2. Mechanical locking device

- Structural Blind Rivets: Mechanical locking structures are added, such as external locking blind rivets (Monobolt), internal locking blind rivets (Interlok), and single/double drum rivets (Avinox, Stavex). These designs are designed to create a “safety lock” by means of grooves, drums or deformation of the locking ring to enhance tensile and shear resistance.

- Standard Blind Rivets: Mostly open rivets or closed type rivets, relying on the physical deformation of the rivet body after expansion to realize the connection, lack of additional locking device, low load carrying capacity.

Custom Blind Rivets for Your Project

Each component of a blind rivet is important, so it makes sense to ensure that each component is of acceptable quality. If you have a need to purchase rivets, then you need to find a reliable rivet manufacturer.

Get Rivets Quote

You may also find these topics interesting

Buy Open Type Blind Rivets

Buy Structural Blind Rivets