blind rivets nickel plating solutions

Nickel-plated blind rivets are a reliable fastening solution that combines mechanical strength with enhanced surface protection. Blind rivets nickel plating provide a bright, corrosion-resistant finish that improves abrasion resistance, electrical conductivity and aesthetics. This makes these rivet finishes ideal for electronic, electrical, decorative assembly and light structural applications.

what is a nickel palted pop rivet?

Nickel plated blind rivets are blind rivets with a nickel metal coating on the rivet surface through an electroplating process. This surface treatment is commonly used for rivet bodies made of carbon steel, copper or brass. The thickness of the nickel layer is usually 3-10 microns, with good adhesion and uniformity. It effectively improves the rivet’s corrosion, wear and electrical conductivity, while giving it a bright silver or matte metallic appearance.

These rivets are particularly suitable for the appearance of consistency, electrical performance or environmental adaptability requirements of the occasion. Such as electronic equipment, household appliances, decorative components and precision assembly areas. Nickel-plated rivets provide longer-lasting, consistent performance in more complex or demanding applications than untreated bare rivets.

Why are blind rivets nickel plated?

Nickel plating is not only a protective layer, but also a functional treatment to improve overall performance and assembly reliability. It is very suitable for blind rivets with high structural strength but requiring a certain surface quality.

- Enhanced corrosion resistance

- Enhance wear resistance and mechanical stability

- Provides good electrical conductivity

- Improve appearance and consistency

- Improve automated assembly suitability

blind rivets nickel plating Process Overview

The nickel plating process for blind rivets is a standardized electroplating process. The purpose of this process is to form a firmly attached, bright and uniform metallic nickel layer on the surface of the rivet. The following is a typical nickel plating process for blind rivets made of carbon steel, copper, brass and other materials:

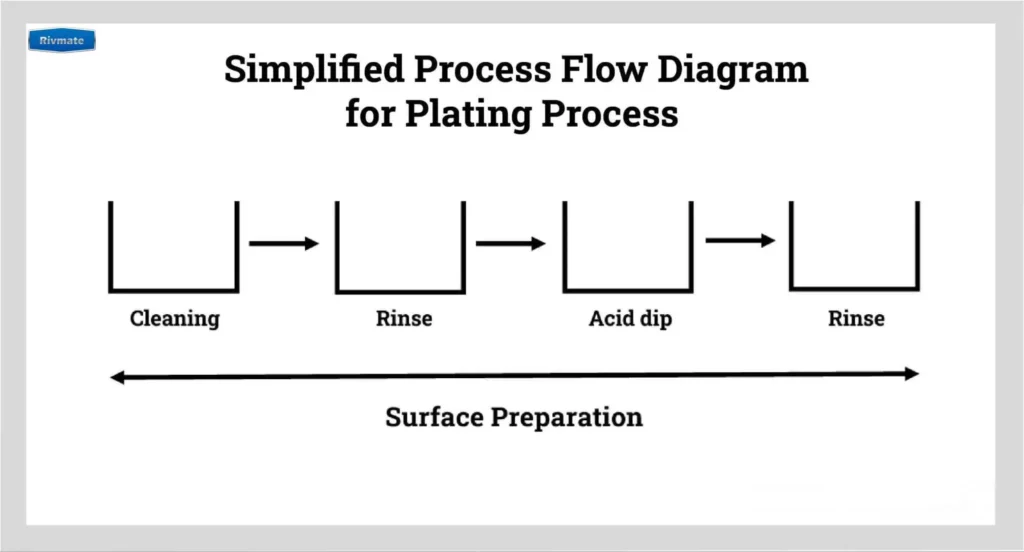

1. Surface Preparation

- Degreasing and oil removal: use alkaline degreasing solution or ultrasonic cleaning to remove surface oil.

- Acid washing and descaling: use dilute hydrochloric acid or dilute sulfuric acid to remove oxidized skin and rust layer.

- Activation treatment: quick pickling or electrolytic activation to enhance the surface activity and improve the adhesion of plating layer.

- Neutralization by washing: Thorough cleaning is required after each pre-treatment process to avoid cross contamination.

2. Nickel Plating Process

Commonly used nickel sulfate type plating solution (Watts nickel plating, composition: nickel sulfate, nickel chloride, boric acid, control pH 3.8-4.5) to carry out the core pulling rivets plating.

- Plating parameters: Temperature: 45-60°C

- Current density: 2-5 A/dm² (depending on part size and density)

- Time: Depending on the desired thickness of the plating layer (generally 5-15 minutes)

and constantly agitated or circulated during the plating process.

3. Post Treatment

Thoroughly rinse the plating residue with water first to prevent corrosion spots from forming on the surface of the core-pulling rivets.

Passivation is then an option. It is used to stabilize the surface of the nickel layer and prevent oxidation discoloration.

Finally use hot air drying or natural drying. Check the plating uniformity, thickness (3-10μm), adhesion and appearance quality.

4. Optional processes (according to product requirements)

- Bright nickel treatment: add brightener to form a mirror effect

- Matte nickel finish: no brightener added, for industrial appearance

- Composite plating (e.g. nickel-tin alloy): for higher corrosion resistance requirements

Applications of Nickel Plating Blind Rivets

- Home Appliances: air conditioners, washing machines, microwave ovens, refrigerators and other metal panels and frame connections.

- Electronics & Electrical Assemblies: Distribution boxes, electrical panels, PCB assembly brackets and other occasions.

- Decorative Fastening: Exposed parts connection for case and bag hardware, furniture ornaments, lighting structures, etc.

- Industrial Equipment: control cabinets, metal enclosures, aluminum structures and other assembly connections.

- Automotive Interior & Light Electrical Modules: non-stressed parts such as interior panels, trims, and electronic control module housings.

- Telecom & Signal Housings: Signal transmitters, power modules, rack assemblies and other structural connections that require conductivity, corrosion resistance and low interference.

Material Compatibility & Limitations

There are certain material compatibility requirements and process application limitations when nickel plating blind rivets.

✅ Applicable materials

- Carbon Steel: nickel plating process is mature, strong adhesion, cost-effective. Suitable for structural rivets to enhance corrosion resistance and surface hardness. Recommended for non-long-term high salt spray environment applications.

- Copper / Brass: close to the electrochemical properties of nickel, excellent adhesion, uniform and bright coating. It retains excellent electrical conductivity and is suitable for electronic and electrical assemblies. At the same time with good decorative, commonly used in furniture, hardware, instrumentation rivets.

⚠️ Limited Applicable Materials

- Stainless Steel: Plating adhesion is limited, special surface activation is required. Complicated process, high cost, prone to risk of de-plating.

❌ Not recommended material

- Aluminum: Aluminum has a naturally occurring oxide film on the surface, making direct nickel plating difficult. If nickel plating is required, the intermediate layer must be pre-treated (e.g. replacement zinc plating or copper plating), which is costly and unstable. Plating in the riveting deformation is easy to peel off, there are potential risks of galvanic corrosion. For aluminum blind rivets, anodizing is recommended instead of nickel plating.

Nickel Plated Blind Rivet Specifications

| Nominal Diameter | Inch Size | Metric Size (mm) | Typical Grip Range | Common Head Types | Recommended Base Materials |

|---|---|---|---|---|---|

| 1/8″ | 3.2 mm | 3.2 × 6 – 10 mm | 1.0 – 5.0 mm | Dome, Countersunk | Carbon Steel, Brass, Copper |

| 5/32″ | 4.0 mm | 4.0 × 8 – 12 mm | 1.5 – 6.0 mm | Dome, Large Flange, CSK | Carbon Steel, Brass |

| 3/16″ | 4.8 mm | 4.8 × 10 – 14 mm | 2.0 – 8.0 mm | Dome, CSK, Large Flange | Carbon Steel, Brass |

| 1/4″ | 6.4 mm | 6.4 × 12 – 16 mm | 3.0 – 10.0 mm | Dome, Large Flange | Carbon Steel only (heavy-duty) |

Additional Parameter Recommendations

- Plating Process: Barrel plating is recommended for batch processing with high efficiency and low cost.

- Stem Type: It is recommended to match with broken-tailed steel core or copper core, which is easy to be beautiful and consistent after riveting.

- Plating thickness: It is recommended to control at 3-8 μm, taking into account the adhesion and corrosion resistance.

Pay attention to avoid the following situations

Pay attention to avoid the following situations:

- Aluminum blind rivets: nickel plating is not recommended (poor adhesion, recommended anodizing)

- Non-standard head type (such as sealing type, structural type multi-section head): many dead corners in the plating, easy to uneven plating

- Too short grip rivets: easy to turn the edge in the rolling plating, resulting in bruising

Surface Treatment Comparison – Black Anodized Pop Rivet vs. Alternatives

| Criteria | Nickel Plated | Zinc Plated | Painted / Powder Coated | Anodized | Plain (Uncoated) |

|---|---|---|---|---|---|

| Applicable Materials | Carbon steel, brass, copper | Carbon steel | Aluminum, steel, stainless steel | Aluminum only | All base metals |

| Corrosion Resistance | ★★★★☆ (dense nickel layer) | ★★★☆☆ (passivated zinc layer) | ★★☆☆☆ (depends on coating quality) | ★★★★☆ (sealed oxide layer) | ★☆☆☆☆ (very poor) |

| Wear Resistance | ★★★★☆ (hard surface) | ★★☆☆☆ (moderate) | ★★☆☆☆ (prone to scratches or chipping) | ★★★☆☆ (moderate, somewhat brittle) | ★★☆☆☆ (base material dependent) |

| Appearance | Bright or matte silver, uniform finish | Dull silver/blue/yellow tint | Wide range of colors, decorative | Silver, black, gold, red, etc. | Raw metal appearance, may discolor |

| Electrical Conductivity | Good | Fair (reduced with passivation) | Poor (non-conductive coating) | Poor (non-conductive oxide) | Depends on base metal |

| Cost | Moderate | Low (cost-effective for bulk) | Moderate to high (especially powder coatings) | Moderate (requires aluminum and proper setup) | Lowest |

| Process Compatibility | Barrel or rack plating, suitable for mass finishing | Barrel plating preferred, well established for steel | Requires curing, limited to accessible external surfaces | Only suitable for aluminum; internal surfaces may be unsealed | Suitable for fast, untreated usage |

| Recommended Applications | Appliances, electronics, decorative hardware | Industrial fasteners, steel assemblies | Consumer goods, panels, low-impact exterior finishes | Lightweight aluminum structures, exposed outdoor parts | Hidden, non-critical joints, low-cost applications |

- Nickel plating: suitable for applications that require a balance of decorative, conductive, and corrosion protection properties, recommended for mid to high-end rivet products.

- Galvanized: suitable for industrial structural parts that pursue a balance between cost and basic protection.

- Spraying: for strong color requirements or appearance parts, but not suitable for high friction or conductive occasions.

- Anodizing: exclusive treatment for aluminum, suitable for lightweight and corrosion resistance requirements of high environment.

- Untreated: Only for non-exposed, non-critical, low-cost connections.