Table of Contents

Pop rivets are widely used for joining plastic materials because of their convenience and stability. They are preferred over other fasteners due to their superior quality. There are many products that use plastics and need to be produced in large quantities with high strength requirements for the connection.

Table of Contents

There is the installation of automotive interiors and automotive plastic components, as well as plastic housings that need to be connected to electronic devices, as well as equipment such as routers, computers and televisions. The cosmetic requirements of these applications and the need for stable connections place high demands on the fasteners.

This article will discuss the importance of pop rivets for plastic. We will discuss the importance of using pop rivets for plastic products. It reduces the cost and time of the project

Characteristics of Plastic Materials

Plastic is arguably one of the most used materials in the world today. With its diverse characteristics, it is used in a wide range of applications, including industry, consumer goods, construction, electronics and automobiles, among many others. Here are some of the key features of plastics:

- Lightweight: Plastic has a very low density, which makes it very popular for applications that require lightweighting. For example, automobiles, electronics, etc., to be able to reduce the overall weight.

- Corrosion Resistance: Plastic does not receive the effects of chemicals, moisture, acidic and alkaline environments.

- Insulating Properties: Most plastics are electrically insulating and are excellent insulators, preventing the passage of electric current.

- Low thermal conductivity: plastics have low thermal conductivity, poor heat transfer ability, and good thermal insulation properties.

- Easy processing: Plastic materials are easy to process and mold, and can be designed into complex shapes, making them suitable for mass production and reducing manufacturing costs.

- Low cost: Compared with materials such as metals or ceramics, many plastic materials are less expensive, especially when mass produced plastic materials are very economical.

What Kind of Pop Rivet Can be Riveted to Plastic?

With the above information, we know some of the main characteristics of plastics. So what do manufacturers pay attention to when riveting plastic?

Compared to metal, the hardness of plastic is relatively low. So using normal high strength pop rivet may damage the surface of plastic or directly destroy the structure of plastic. If your plastic project requires the use of metal rivets, then I suggest you use large flange head pop rivets or tri fold rivets which have a larger head area.Of course, plastic pop rivets can also be used to rivet plastic.

Best Pop Rivets for Plastic

We believe that when selecting pop rivets, manufacturers want to get a stable connection without damaging the plastic material. Then it is very important to choose the type of pop rivets. Below are a few types of Pop rivets that are best suited for riveting plastic materials:

Large Flange Pop Rivets

Features: The head area is larger than standard rivets, which can disperse the stress.

Applicable scenarios: large flange head rivets are particularly suitable for soft or thin plastic materials, providing a larger pressure-bearing surface to prevent material damage or deformation.

Advantage:

- Provides a larger contact surface, reducing the concentrated pressure of the rivet on the plastic.

- Ideal for joining lightweight and fragile materials such as PVC, ABS, etc.

Multi Grip Blind Rivets

Features: able to adapt to the range of materials with different thicknesses and reduce the strict requirements for rivet length.

Applicable scenarios: for plastic materials with uneven thickness or a combination of multiple materials, such as electronic shells, automotive interiors and so on.

Advantage:

- One rivet for a wide range of material thicknesses, reducing the need for rivet inventory.

- Provides a strong connection and is suitable for plastics that are soft or of varying thicknesses.

Plastic Pop Rivets

Features: made of durable plastic material, lightweight and flexible.

Scenarios: suitable for applications where metal corrosion or conductivity needs to be avoided, such as electronic equipment, lightweight plastic structures, etc.

Advantage:

- Will not cause excessive pressure on the plastic, avoid hard metal rivets on the soft material damage.

- Provide good corrosion resistance, suitable for wet or corrosive environments.

Colored Pop Rivets

Features: Different colors of rivets can be provided according to the demand, in line with the need for decoration or marking.

Applicable Scenario: suitable for decorative plastic products or occasions where color marking is required, such as furniture, display equipment, etc.

Advantage:

- Can be matched with plastic color to provide a beautiful appearance effect.

- Increase visual appeal while maintaining functionality.

Peel Type Blind Rivets

Characteristics: The tail of the rivet peels off like a petal during installation, creating a larger fixing area.

Applicable Scenario: Suitable for softer or thinner plastic material connection, providing a larger support surface to avoid material cracking.

Advantage:

- Rivet tail expands to provide strong grip and stability.

- Ideal for fragile or soft plastic materials such as PVC, PS, etc.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Benefits of Using Pop Rivets for Plastic

Single-sided Operation and Easy Installation

Pop rivets can be riveted by operating from only one side, which is very useful for plastic products.

When it comes to plastic equipment, containers and electronics housings that need to be mounted from a single side, the advantages of pop rivets will become apparent. This is not possible with other fasteners.

No Damage to Plastic Surfaces and Structures

Pop rivets come in many types. Large flange head pop rivets that distribute stress. This type of pop rivets prevents excessive concentrated pressure on the plastic material during riveting, avoiding rupture or deformation.

In some softer or brittle plastics, such as PVC, ABS, PP, etc., LARGE FLANGE POP RIVETS ensure that the plastic surface is not damaged.

Reduces the Overall Weight of the Product

Pop rivets (especially aluminum or plastic rivets) are very light in weight. Ideal for plastic structures that need to be lightweight to avoid putting too much load on plastic parts.

Efficient and Fast Installation

Pop rivets are very simple to use. They require only a manual or pneumatic rivet gun for quick installation. A large number of pop rivets for plastic are used in some high volume plastic product lines such as plastic frames, appliance housings, and more.

Suitable for a Wide Range of Plastics

The same Pop rivets can be adapted to a wide range of plastic materials, whether it is soft polyethylene (PE), polypropylene (PP), or harder nylon (PA), ABS, can provide a solid connection effect.

When your project has different kinds of plastic products and components, pop rivets can help you save a lot of labor and financial costs.

No Special Surface Treatment Required

Using Pop rivets for plastics eliminates the need for complex surface treatments. If you use other joining methods, such as welding. Then you need to clean or rust-proof the surface before and after installation.

Prevents over-tightening

The installation process of Pop rivets is tool-controlled. It prevents over-tightening of the material. Unlike screws or bolts, Pop rivets do not exert excessive pressure on the plastic material once installed.

Cost Savings

Compared to welded or bolted connections, Pop rivets do not require expensive equipment or highly skilled operators. And the installation process is very simple and fast, greatly reducing production and labor costs.

This advantage makes pop rivets ideal for mass-produced plastic products such as consumer electronics, automotive parts, plastic piping and more.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Install Pop Rivets without Destroying the Plastic?

After you have determined which type of pop rivets you are using for your project, you will be faced with the problem of installing them correctly.

One special feature of a pneumatic rivet gun is the ability to adjust the pressure at which the pop rives are installed. So when you use a pneumatic rivet gun, make sure that you adjust the riveting pressure to avoid applying too much force to the plastic. If you want to rivet thicker plastic materials, you can gradually increase the riveting pressure and avoid applying too much force at one time, which will make the expansion process of the rivet more even and reduce the impact on the plastic.

Applications of Pop Rivets for Plastic

Pop rivets have a wide range of applications in plastic materials, especially where lightweight, robust, one-sided operation is required. The following are examples of specific applications for Pop rivets in plastics:

Electronic Equipment Shell

Assembly of plastic shells, such as routers, computers, televisions, audio equipment and so on. If you use screws to fix it, it is easy to cause over-tightening problem and not beautiful enough. pop rivets can provide fast and solid connection to make sure the housing is tight and beautiful.

Household Appliances

There are many types of household appliances, such as washing machines, refrigerators, microwave ovens, air conditioners and so on. The connection of their plastic casing and supporting structure requires the use of Pop rivets to fasten them to the internal structure of the appliance. This ensures the solidity of the appliance shell and reduces the assembly cost and time, which is especially suitable for mass production.

Automobile Interior

In order to reduce the risk of car accidents to the occupants, automotive interiors are generally constructed with plastic. Pop rivets are widely used in automotive interiors to secure plastic panels to the body structure. Because it provides a strong connection between lightweight plastic and metal parts, it is particularly suitable for assembly areas where the backside is not easily accessible.

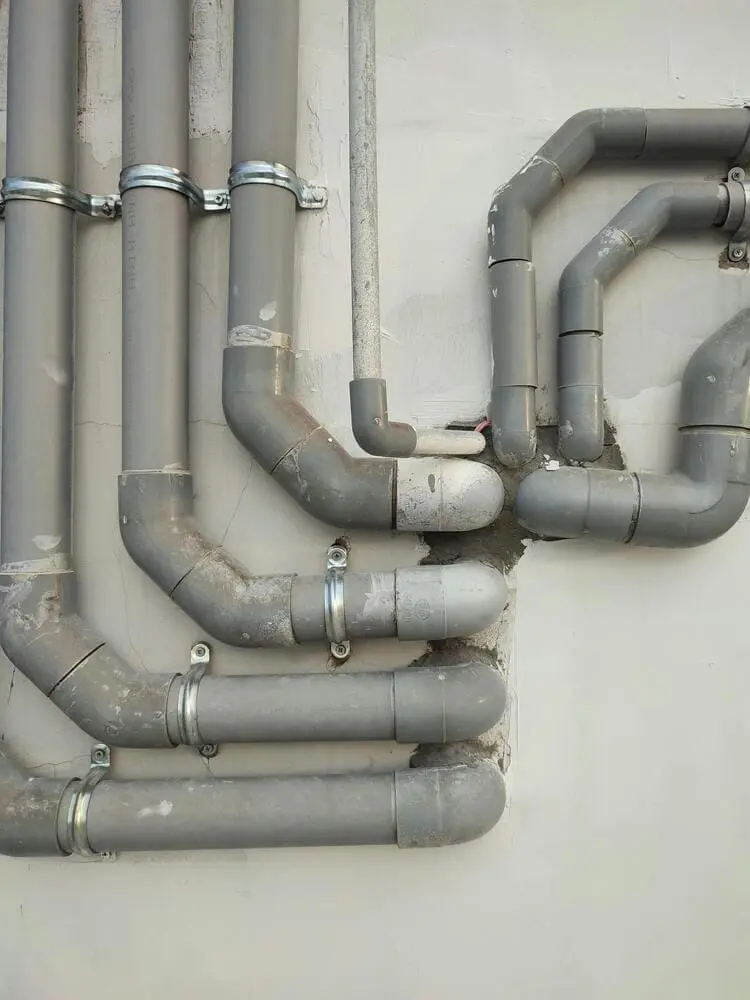

Plastic Pipes and Pipe Support

Pop rivets are used to connect plastic pipes to supports or fixing components, providing a strong fastening in one-sided operation, ensuring a reliable and environmentally friendly connection of the piping system.

Conclusion

There is a wide variety of fasteners for connecting plastic materials. But pop rivets for plastic offer a simple installation process and faster installation efficiency. Pop rivets can connect many different plastic materials.

Rivmate offers a range of pop rivets for riveting projects.We offer pop rivets for plastic, high strength structural rivets and corresponding installation tools.

Revolutionize Your Plastics Projects with Our Pop Rivets!

Rivmate offers high quality pop rivets that can take plastic joining to the next level. Contact us today to learn more about our pop rivets. Revolutionize the way you connect plastic products and equipment with our customized riveting solutions for your project. If you’re not sure which one is right for your needs, we offer free samples to our customers.