Lockbolt Rivet (Magna Lok Rivets)

Rivmate Lockbolt Fastener Supplier – Provide Security For Your Project With Lockbolt Rivet

What is Lockbolt Rivet?

Lockbolt Rivets are a commonly used connecting piece. It usually consists of two parts: the rivet and the rivet nut. A section of the rivet has an annular groove, while the rivet nut has a matching convex groove. The two are joined together by inserting the rivet into the convex groove of the rivet nut and then compacting it firmly.

Lockbolt Rivet is a new type of riveted fastener. Lockbolt Rivets can achieve very high joint strength.

Rivmate produces a wide range of lockbolt rivets at competitive prices. The quality is reliable and strictly tested. We are happy to establish long-term cooperation with you.

Rivmate High Strength Lockbolt Rivet

| Material | Carbon Steel |

| Standard | ISO,DIN7337,IFI114,HUCK,AVDEL etc. |

| Non-standards | OEM is available, according to drawing or samples |

| Finish | Green trivalent electroplating blue white zinc |

| Certification | ISO 14001,ISO9001,IATF 16949 |

| Package | according to cuntomers requirement |

| Grip Range | 1.6-89.0 |

Head

Rivet Lever

Advanges of Lockbolt Rivet

- Clear Cut: The retaining ring undergoes precise shearing during installation, forming a stable, repeatable mechanical locking structure.

- Fast Installation Speed: Completed in a single riveting operation, eliminating the need for tightening or reinspection, significantly boosting assembly efficiency.

- Low Overall Installation Cost: Short installation time and low rework rate effectively reduce comprehensive labor and assembly costs.

- Superior Fatigue Strength: The mechanical locking structure withstands high-frequency vibration and cyclic loads, delivering outstanding fatigue resistance.

- Excellent Seismic Performance: Connections resist loosening under shock and vibration, making them suitable for dynamic conditions and applications with high seismic requirements.

- Ergonomically Designed Mounting Tools: Installation tools feature ergonomic design to reduce operator fatigue and enhance work stability.

- Low Noise During Installation: Minimal noise during assembly improves the on-site working environment.

- No Repetitive Stress Damage: Eliminates reliance on repeated tightening motions, reducing the risk of repetitive strain injuries for operators.

- No Secondary Operation Required: Final connection is achieved upon installation completion, eliminating the need for additional retightening or secondary processing.

The Technical Parameters of Lockbolt Rivet

| Grip Range(Min) | Grip Range(Max) | Hole Size | Tensile | Shear |

|---|---|---|---|---|

| 4.8 | 27.0 | 5.1 | 7500N | 7800N |

| 1.6 | 27.0 | 6.6 | 12500N | 13500N |

| 3.2 | 34.9 | 8.2 | 21000N | 21500N |

| 3.2 | 34.9 | 9.8 | 30000N | 31000N |

| 6.4 | 89.0 | 13.5 | 76000N | 64000N |

| 6.4 | 89.0 | 17.0 | 120000N | 100000N |

| 6.4 | 82.6 | 20.5 | 181800N | 146900N |

| 12.7 | 89.0 | 23.5 | 250000N | 196000N |

HOW TO CHOOSE

How Does a Lockbolt Rivet Work?

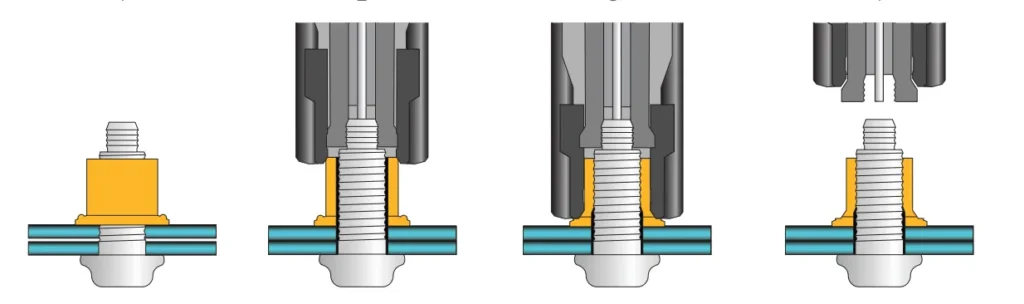

Lockbolt Rivet is a mechanical locking fastener designed for high-strength structural connections, commonly used in bridges, rail transit, and heavy equipment. Its operation relies on the cold-formed locking of the pin and collar, rather than threaded preload.

During installation, a specialized tool applies tension to the pin while pressing the collar into the pin’s locking groove. As tension increases, the collar undergoes plastic deformation and becomes permanently locked within the groove. Upon completion of the locking process, the pin shank fractures under a predetermined load, instantly finalizing the connection.

Lacking threaded structures, Lockbolt Rivets do not experience preload decay due to vibration. Their fatigue and vibration resistance significantly outperform traditional high-strength bolts, making them particularly suitable for structures enduring long-term dynamic loads.

The entire installation process is tool-controlled, ensuring consistent clamping force and straightforward operation. Post-installation, connection quality is verified through visual inspection of the formed lock ring and broken pin, making it suitable for high-efficiency, high-reliability industrial assembly applications.

Considerations

Key Lockbolt Rivet Considerations for Structural Applications

1. Vibration and Fatigue Performance Matters

The core advantage of the Lockbolt Rivet lies in its exceptional resistance to vibration and cyclic loading. Its lock ring is cold-formed into the rivet’s groove to create a permanent lock, preventing the connection from loosening due to vibration—a feat difficult to achieve with traditional bolts and rivets. For this reason, Lockbolt Rivets are frequently used in heavy-duty structures demanding vibration resistance and fatigue strength, such as rail transit systems, heavy-duty vehicles, and bridge components.

2. Installation Accessibility and Tooling for Lockbolt Rivets

Installation Space Requirements

Installation of Lockbolt Rivets typically requires simultaneous access to both the pin and collar sides. This necessitates sufficient clearance behind the installation location for tool access. Therefore, prior to design and construction, it is essential to verify that the riveting area possesses adequate access space.

Specialized Installation Tools

The mechanical locking process for Lockbolt Rivets requires specialized installation tools, not standard rivet guns. These tools grip the pin and pull it while simultaneously compressing the collar, cold-forming the collar into the pin’s groove to create a permanent mechanical lock.

Installation tools come in various types, including manual, pneumatic, and hydraulic.

- Manual Tools: Suitable for smaller Lockbolt sizes or field repairs, requiring no external power source.

- Pneumatic/Hydropneumatic Tools: Ideal for medium-volume production or field assembly, providing sustained tensile force output to reduce operator fatigue.

- Hydraulic Tools: Suitable for large-sized, high-volume production environments, delivering higher pull force output and stability.

Selecting the appropriate tool type is critical to ensuring complete cold forming of the retaining ring and consistent clamping force. Insufficient pull force or lateral displacement of the tool may result in incomplete locking or an unreliable connection.

Pull Force and Installation Precision

Different tools feature varying pull force output parameters. For instance, certain hydraulic installation tools deliver pull force outputs exceeding 5,000 lbs (approximately 22 kN) under high-pressure conditions, making them suitable for installing large-diameter or high-strength Lockbolt Rivets.

3. Material Selection and Corrosion Resistance

The selection of materials for Lockbolt Rivets significantly impacts joint performance under varying materials and environmental conditions. Commonly used rivets typically employ high-strength carbon steel or stainless steel to enhance shear and tensile strength, while surface treatments such as plating can further improve corrosion resistance. For outdoor or high-humidity environments, prioritizing materials with higher corrosion resistance grades constitutes standard engineering practice.

4. Clamp Force Consistency

Clamping Force Consistency refers to the near-identical clamping force achieved at each lock rivet connection point post-installation. For structural-grade fasteners, this property serves as a critical metric for evaluating joint reliability. Lockbolt Rivets derive their clamping force primarily from cold-formed mechanical locking, rather than the torque-tightening method used in conventional bolts.

Differences Between Lockbolt and Torque Tightening

Traditional bolt tightening relies on rotational torque to generate preload. Even when technicians use standard torque tools, factors like friction and surface variations cause significant variations in actual clamping force per bolt. Multiple engineering tests show that even with consistent torque, clamping force can still exhibit noticeable fluctuations.

In contrast, Lockbolt Rivets derive their clamping force from the tool’s direct pulling of the pin and cold-forming of the locking ring. This method closely resembles direct tension control, enabling the rivet to achieve a highly consistent preload state upon completion.

Why Consistency Matters

In structural connections, inconsistent clamping forces lead to uneven load distribution. Concentrating loads on a few connection points increases fatigue failure risk. Conversely, consistent clamping forces ensure uniform load distribution, enhancing the system’s overall fatigue life and vibration resistance.

Lockbolt's Consistency Advantage

The Lockbolt Rivet’s unique mechanical locking mechanism generates stable clamping force during every installation. It achieves this by cold-forming the lock ring to fill the rivet groove, creating a tight metal-to-metal contact. This ensures each connection point receives a similar clamping force level, contributing to enhanced long-term structural stability.

Because Lockbolt relies on direct tensile action rather than rotational friction, its clamping force exhibits minimal variation across most tests. Industrial fastener studies indicate that structurally similar rivets maintain clamping force deviations within ±5% post-installation. This ensures highly consistent clamping states across multiple connection points, thereby enhancing the mechanical uniformity and durability of the entire structure.

5. Permanent Connection and Maintenance

Once established, Lockbolt Rivet connections are permanent and typically do not permit easy disassembly. This offers significant benefits in extending maintenance intervals and enhancing overall stability, but it also means that if structural disassembly is required later, destructive removal methods must be employed. Therefore, maintenance requirements and disassembly plans should be confirmed during the design phase.

6. Application Suitability and Design Integration

Lockbolt Rivets are widely employed in industries demanding high strength and reliability, including heavy-duty transportation equipment, machine tools, bridges, and steel structures. In these applications, structural connections must not only deliver high load-bearing capacity but also maintain long-term stability. When selecting Lockbolt Rivets, comprehensive design evaluations should consider connection loads, vibration environments, and long-term usage conditions.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

INSTALLATION

Installation Guide for Lockbolt Rivet

1. Preparation and Safety Inspection

Before installing Lockbolt Rivets, confirm that all workpieces have been drilled with appropriate holes. The hole diameter should fit snugly with the rivet diameter without interference, allowing the pin to pass smoothly through the workpiece. Tools typically used for Lockbolt installation include specialized rivet guns or hydraulic/pneumatic installation tools. Ensure these tools are in good working condition and have undergone safety inspections. Operating installation tools without training or protective equipment poses potential risks.

2. Positioning the Pin and Collar

Insert the Lockbolt Rivet pin into the pre-drilled hole from one side, then slide the collar onto the opposite end of the pin. The pin head should rest against the back of the workpiece, while the collar faces the front side. No torque is required during preparation; the fit is achieved solely through dimensional accuracy.

3. Applying Preload with the Installation Tool

Align the nose cap of the installation tool with the pin’s tail end, ensuring the tool’s axis is parallel to the pin. Begin pulling the pin. Under tension, the pin gradually draws into the hole, tightly clamping the workpiece while compressing the collar into the pin’s groove. This process requires no threaded tightening, thus avoiding preload decay.

4. Lock Ring Swaging and Final Connection

As tension continues to increase, the lock ring undergoes plastic deformation (swaging) within the pin groove, forming a permanent mechanical locking structure. A powerful clamping force is established between the lock ring and pin. Unlike traditional bolt fastening, this process relies neither on friction nor lock washers.

5. Pin Tail Breakage and Quality Inspection

When tension reaches the rivet’s design break point, the pin tail fractures and either sheds or is retrieved by the tool. The fractured lock ring remains on the pin, completing the permanent connection. Post-installation, visually inspect the lock ring for full forming and verify the pin head’s flush fit with the workpiece to confirm installation quality.

6. Installation Consistency and Multi-Point Assembly

The Lockbolt Rivet installation process is tool-controlled for both tension and forming, ensuring highly consistent clamping force independent of manual torque. This consistency is particularly critical for structural connections, reducing quality variation in mass production and enhancing product reliability.

APPLICATIONS

Applications of Lockbolt Rivet

Bridges and Steel Structures

Used in critical connection points for bridges and large steel structures, providing long-term stable high strength and fatigue resistance.

Rail Transit Systems

Applied in rail vehicles and track structures, capable of withstanding continuous vibration and cyclic loads.

Heavy Construction Equipment

Suitable for structural connections in construction machinery and heavy equipment, ensuring no loosening under high-load conditions.

Commercial Vehicles and Trucks

Frequently used in chassis and body structural connections, enhancing vehicle reliability during long-term operation.

Energy and Power Equipment

Employed in power generation equipment and energy infrastructure, meeting stringent requirements for connection strength and durability.

Industrial Machinery and Frames

Suitable for permanent connections in industrial equipment and steel frames, improving overall structural stability.

FAQs - Lockbolt Rivet

Q1. What Is a Lockbolt Rivet?

A Lockbolt Rivet is a structural mechanical locking fastener consisting of a pin and a collar. It achieves permanent locking through cold forming and is widely used in high-strength, high-reliability structural connections.

Q2. How Does a Lockbolt Rivet Differ from a Bolt?

Unlike traditional bolts that rely on torque preload, the Lockbolt Rivet generates stable clamping force through mechanical locking. It resists loosening due to vibration or aging, making it ideal for dynamic loads and high-fatigue conditions.

Q3. Does a Lockbolt Rivet Require Special Tools?

Yes, Lockbolt Rivets require specialized installation tools to complete the cold forming of the collar and the breaking of the pin. These tools ensure consistent clamping force, enhancing installation quality and assembly efficiency.

Q4. Are Lockbolt Rivets Removable?

Lockbolt Rivets provide a permanent connection and cannot be directly disassembled after installation. Removal typically requires cutting or destructive methods.

Q5. Where Are Lockbolt Rivets Commonly Used?

Lockbolt Rivets are widely used in bridges, rail transportation, heavy equipment, commercial vehicles, and industrial steel structures—applications demanding high strength, vibration resistance, and durability.