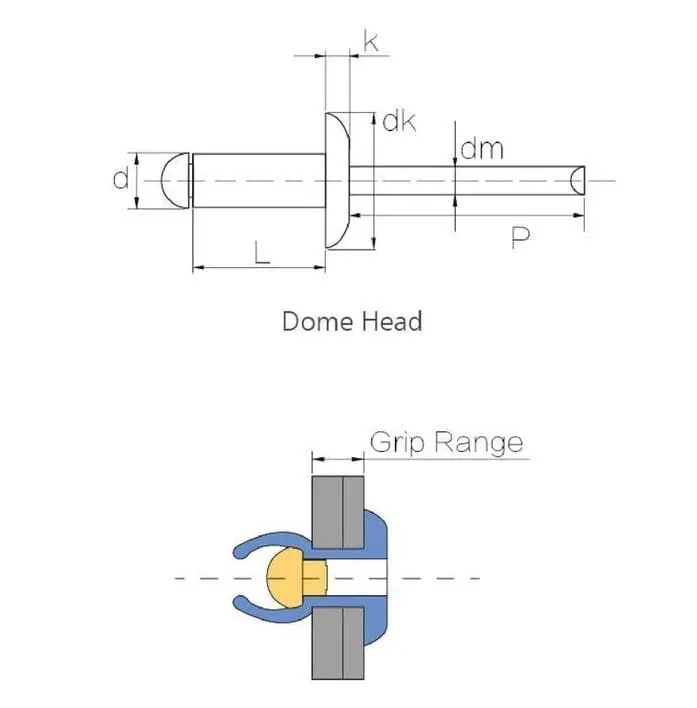

Dome Head Blind Rivets

Dome Head Blind Rivets are among the most widely used blind rivet fasteners. Their universal design and stable installation make them extensively employed in various industrial assembly applications. The dome-shaped head evenly distributes force during riveting, reducing the risk of surface deformation and enhancing connection reliability.

In practical applications, Dome Head Blind Rivets are renowned for their effortless installation. Riveting can be completed from a single side, making them ideal for structures inaccessible from the rear. Their strong tolerance for hole positional variations improves assembly consistency and reduces rework. This adaptability is a key reason for their widespread adoption in sheet metal assembly and mass production.

If you’re seeking a versatile, reliable, and cost-effective blind rivet solution, Dome Head Blind Rivets are the ideal choice. Feel free to contact our engineering team anytime for selection guidance or customized quotes.

Rivmate – Top Pop Rivet Manufacturer in China

Rivmate is a specialized manufacturing facility dedicated to the R&D and production of pop rivets. Recognized globally for its consistent quality, comprehensive product range, and reliable delivery capabilities, Rivmate stands as China’s leading Pop Rivet Manufacturer. We provide mature, mass-producible blind rivet solutions for diverse industries and applications.

Our product portfolio features a full range of blind rivets, encompassing multiple common head types and structural designs, including Dome Head Blind Rivets, Countersunk Head Blind Rivets, and Large Flange Blind Rivets. Different head types address diverse requirements for appearance, load distribution, and assembly conditions, making them suitable for applications ranging from lightweight assemblies to industrial-grade use.

Leveraging our in-house manufacturing facilities and proven production processes, Rivmate delivers significant advantages in batch consistency and quality stability. Through rigorous raw material control and process inspection, we ensure every batch of blind rivets maintains uniformity in dimensions, tolerances, and performance. This helps customers reduce rework rates and assembly risks—a critical factor for high-volume procurement and long-term projects.

Whether your industry is automotive, home appliances, sheet metal fabrication, HVAC, or other industrial sectors, Rivmate delivers reliable supply capabilities and expert selection support for any project with ongoing or large-scale blind rivet requirements. Feel free to contact us anytime for quotes or technical advice. Our engineering team will assist you in selecting the most suitable blind rivet solution.

Applications of Dome Head Blind Rivets

Application areas: door panels, roof, fenders, chassis components, body frames.

- Used to secure the connection between the door panel and the frame to ensure a stable, tight fit.

- Between the fenders and the body frame, it is used to provide a strong connection while being able to withstand the vibration of the vehicle.

- Installed at the connection between the roof and the body frame, used to maintain the structural integrity of the roof.

- Connections between chassis components, especially where dynamic loads are applied, use dome head rivets to enhance structural stability.

Building and Construction

Application areas: metal frames, curtain wall systems, parapets, roof coverings.

- Used to connect the metal frames of building steel structure to ensure a strong connection between steel beams and steel columns.

- When installing metal brackets for glass curtain walls, dome head rivets are used to fix the connection between metal brackets and frames to ensure the stability and aesthetics of the exterior wall system.

- Used for the connection between outdoor parapets and support beams, the rivets are able to withstand changes in the external environment and maintain stability over time.

- Installed between metal roof panels and support beams to prevent loosening and displacement of roof panels and ensure the durability of the roof.

Furniture Manufacturing

Application parts: metal frame furniture, cabinet door hinges, table and chair supports.

- Used to connect various parts of metal frame furniture, such as the connection between table legs and table top frame, to ensure the stability of the furniture.

- Installed between cabinet door hinges and cabinet frames to provide strong support and firm connection to ensure proper opening and closing of cabinet doors.

- Used for the connection between chair brackets and seats to ensure the safety of chairs when bearing weight.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Advantages of Dome Head Blind Rivets

Dome Head Blind Rivets are among the most common and widely used types of blind rivets, offering a good balance between structural performance, cost control, and aesthetic appeal. They are suitable for most general assembly applications.

1. Balanced Tensile and Shear Strength

Compared to other head types, dome head blind rivets deliver stable and balanced tensile and shear strength. The rounded head design helps distribute forces evenly, minimizing localized stress concentrations. Additionally, its low protrusion height avoids significant interference with structural integrity or visual aesthetics. This construction ensures connection stability while maintaining both functionality and appearance.

2. Cost-Effective Solution

Dome Head Blind Rivets typically feature lower unit costs. Their mature manufacturing processes and high production efficiency enable cost control for entire projects while meeting performance requirements—a key advantage over more complex head types like countersunk or specially formed heads. This cost-effectiveness explains their widespread adoption in high-volume industrial assembly.

3. Better Protection Against Material Deformation

During the riveting process, the dome-shaped structure distributes pressure more evenly, reducing the risk of damage to the connected materials. Unlike countersunk blind rivets, dome head blind rivets do not require pre-drilling countersunk holes, making them less likely to cause material cracking, deformation, or localized collapse. This advantage is particularly pronounced for thin sheet metals or softer materials.

4. Clean and Aesthetic Appearance

Once installed, dome head blind rivets present a smooth, hemispherical appearance, delivering a clean and uniform visual effect. In applications demanding aesthetic appeal—such as decorative metalwork, furniture manufacturing, and electronic device enclosures—Dome Head Blind Rivets maintain excellent surface quality without compromising structural integrity.

Suitable Material Connections for Dome Head Blind Rivets

Dome Head Blind Rivets offer a key advantage in their broad material compatibility. Featuring a large load-bearing contact surface and stable forming structure, these rivets provide reliable connections across diverse material combinations. They ensure strength while minimizing material damage risk, making them widely used in industrial and civil applications.

Metal-to-Metal

Ideal for joining metals like steel, aluminum, copper, and stainless steel. The dome shape helps distribute stress, making it a staple for metal framing, steel plate joining, and general industrial assembly.

Metal-to-Plastic

Suitable for joining aluminum, stainless steel with plastics, PVC, and similar materials. The round head provides more uniform compression on plastic during riveting, reducing cracking risks. Commonly found in automotive body panels, electronic device housings, and appliance manufacturing.

Metal-to-Composite Materials

Suitable for joining steel or aluminum to glass fiber, carbon fiber, and composite panels. Round-head pop rivets provide a larger bearing surface area, helping protect the composite surface layer. Commonly used in automotive lightweight structures and certain aerospace components.

Plastic-to-Plastic

Used for joining plastics like ABS, PVC, and PP. Compared to screws, round-head pop rivets distribute stress more evenly in light-load applications, making them suitable for electronic enclosures, consumer goods, and lightweight structural components.

Wood-to-Metal

Suitable for joining wood, plywood, and metals like steel or aluminum. The rounded head minimizes localized indentation on wood surfaces, making it common in furniture manufacturing and architectural finishes.

Wood-to-Plastic

Used for combining wood with plastics like PVC or ABS, ideal for outdoor furniture and decorative panels. Simple installation enhances assembly efficiency.

Thin Sheet Materials

Ideal for joining thin metal sheets, plastic sheets, and composite sheets. The round-head blind rivet provides greater support area for thin sheets, reducing deformation risks. Widely used in automotive interiors, architectural decoration, and appliance housings.

Dome Head Blind Rivets are Suitable for Which Load and Stress Environments?

Dome Head Blind Rivets provide reliable connections under various load and stress conditions due to their uniform force distribution across the rounded head and stable back-forming properties. Below are typical application environments and engineering specifications:

Tensile Load Environments

Suitable for metal structural connections, automotive body panels, building frameworks, etc. The dome head structure helps distribute tensile forces, reduces localized stress concentration, and maintains connection stability. Engineering practice demonstrates consistent performance in light to medium tensile load conditions.

Shear Load Environments

Ideal for primarily shear-loaded connections like metal plate overlaps and frame assemblies. The rounded head provides a larger bearing surface, enhancing shear load capacity and reducing the risk of plate slippage.

Dynamic Load & Vibration

Suitable for vibrating environments in machinery, vehicles, and certain aerospace applications. When properly selected (diameter, material, clamping range), round-head blind rivets maintain good resistance to loosening under cyclic loading.

Heavy Load Environments

Suitable for heavy-duty applications in machinery, steel structures, and bridge components, but requires larger diameters, appropriate materials (e.g., steel/stainless steel), and sufficient clamping range. For extreme loads, consider structural blind rivets or lock rivets.

Compression Stress Environments

Suitable for fastening rigid materials like metal-to-metal or metal-to-plastic. The rounded head shape helps withstand compressive stress and protects surfaces, minimizing indentation and deformation.

Thermal Expansion-Induced Stress

Ideal for scenarios with temperature fluctuations, such as building facades, outdoor equipment, and mechanical installations. Round-head blind rivets accommodate stress variations caused by thermal expansion and contraction within a certain range, reducing the risk of connection failure.

Multi-Directional Stress Environments

Used for complex connections subjected to simultaneous tension, shear, and vibration. Through proper rivet sizing and material selection, round-head blind rivets deliver stable performance under multi-directional forces.

Will Dome Head Blind Rivets Rust in Wet Environment? What Kind of Surface Treatment is Required?

Whether or not Dome head blind rivets will rust in a humid environment depends on the materials used and the technology used to finish the surface.

Dome head blind rivets are generally made from the following materials.

- Carbon Steel

- Stainless Steel

- Aluminum

If your project uses carbon steel blind rivets in a wet environment, they will rust easily. You will need to use some surface preparation to change this result. For example, galvanizing to prevent carbon steel from coming into contact with water and air.

Aluminum blind rivets are naturally good at resisting corrosion. Of course, with an anodized surface treatment, its corrosion resistance will be further improved.

Stainless steel blind rivets are inherently extremely resistant to corrosion. It is ideal for use in wet environments. And the use of stainless steel blind rivets does not require surface treatment at all.

How to Remove Dome Head Blind Rivets?

Dome head blind rivets are generally considered permanent connections. Once installed, they usually cannot be easily removed. If a blind rivet must be removed, it can only be disabled by destroying the structure of the dome head blind rivets. The following two methods have been used to accomplish removal:

- Drilling:Using an electric drill and an appropriately sized drill bit (usually slightly larger than the rivet diameter), drill through the head of the rivet until it is completely removed.

- Sanding or cutting:The head of the rivet is smoothed or removed using a sanding tool or cutter, and then the remaining portion is removed from the hole by pushing or pulling.

If you want to take an in-depth look at how to remove blind rivets , you can read this article “Best Ways to Remove Rivets?”.

Why Order Dome Head Blind Rivets from Rivmate?

Lower Price

As a blind rivet manufacturer, we provide our customers with large quantities of blind rivets. Because we accept bulk orders from our customers, the unit price of rivets is much lower.

Huge Inventory Warehouse

Our factory has a warehouse of 3,000 square meters. Fast supply of rivet products for your project. Our warehouse stocks commonly used rivet sizes in the market and we have a stable inventory for our long term customers. We are likely to have the dome head blind rivets you need in stock for immediate shipment.

Small and large orders are welcome

We, as a rivet factory, have a minimum order quantity requirement (MOQ 50K for general rivets and MOQ 10K for structural rivets).No matter how big your order is, we can provide it for you quickly and with guaranteed quality.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!