Table of Contents

Both magnalock and monobolt are used in load bearing areas. Do you know the difference between magnalock and monobolt?

This guide will give you a comprehensive overview of the difference between magnalock and monobolt, including magnalock vs monobolt, and their advantages and disadvantages.

Table of Contents

What Are Magnalok Rivets?

Magnalok rivets are high strength structural rivets with internal mechanical locking. It provides reliable tensile and shear strength through a unique mandrel locking mechanism that firmly secures the mandrel within the rivet body.

Magnalok rivets have excellent vibration resistance and are therefore often found in applications where high reliability and high dynamic load adaptability are required. It is ideal for use in automotive, aerospace, rail transportation and heavy industry.

Our rivet factory uses a 5-die machine to produce magnalok rivets with an average of 80 cores per minute and a 6-die machine to produce rivet bodies with an average of 90 cores per minute. Currently, our average production capacity for magnalok rivets is 6 million rivets per month.

Pros and Cons of Magnalok Rivets

As a structural rivet most commonly used as a blind rivet, it has a lot of other rivets do not have the advantages of the rivet. Of course it also has disadvantages. The following are some of the common advantages and disadvantages.

Pros of Magnalok Rivets

- High-strength connections: excellent tensile and shear resistance for high-load, high-stress scenarios. Stable connection even under dynamic loads and high vibration environments.

- Excellent vibration resistance: the mandrel is firmly fixed in the rivet body by a mechanical locking device, preventing the mandrel from coming loose. The connection points will not loosen or fail in vibration environments.

- Strong sealing performance: Ideal for application scenarios that require waterproofing and dustproofing.

Cons of Magnalok Rivets

- Higher cost: The unit price is significantly higher than ordinary blind rivets, which may not be cost-effective in budget-sensitive projects.

- Not suitable for low intensity demand scenarios: in light or low load connection scenarios, the functionality may be excessive and not cost effective.

- Installation Equipment Dependency: Specialized rivet guns or automated equipment are required, and the installation tool needs to provide sufficient tension to accomplish mandrel locking.

Do You Have Any Questions?

Let Us Solve Your Problem

What are Monobolt Rivets?

Like magnalok rivets, monobolt rivets are high-strength blind rivets. It is designed to meet the demands of joining in demanding environments. Likewise, once it is installed, the mandrel is securely locked into the rivet body, creating a strong, reliable, permanent connection.

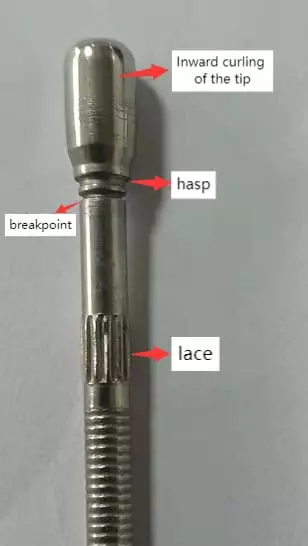

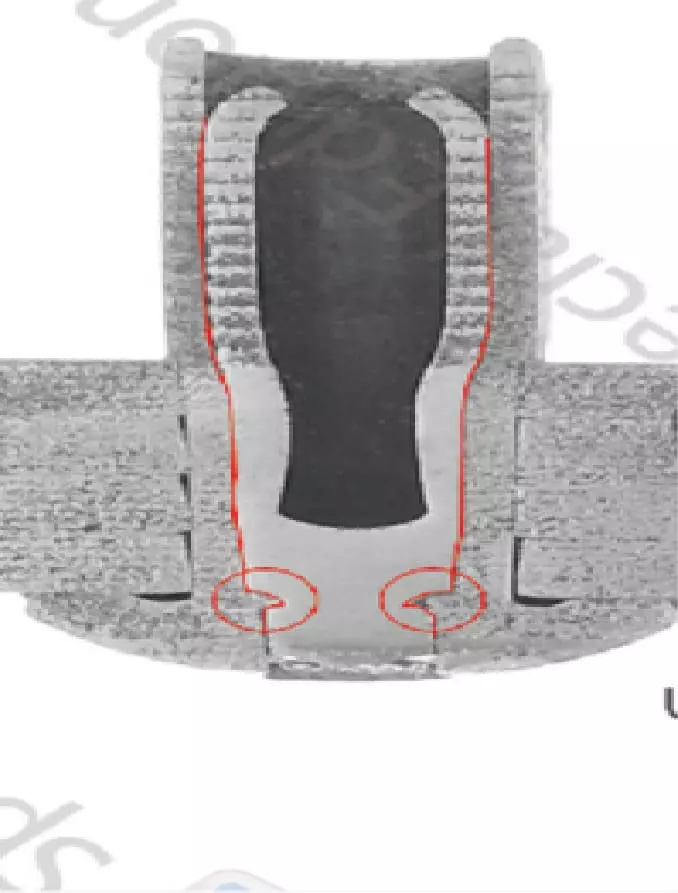

The most important feature of Monobolt rivets is the excellent locking core effect, which can be seen directly by the naked eye visiting the cupping step.Monobolt rivets rely on the embossing at the top of the rivet shell to secure the core and rivet body. Without the embossing, the rivet shell and core will separate and fall off.

Currently, the capacity of monobolt rivets in our rivet factory averages 3 million/month. It can meet your high volume order requirements!

Pros and Cons of Monobolt Rivets

The advantages and disadvantages of Monobolt rivets are more similar to those of magnalok rivets. The application of these two rivet types is also very consistent. Below are the common pros and cons of monobolt rivets.

Pros of Monobolt Rivets

- High strength connection: outstanding resistance to tension and shear.

- Anti-vibration: mandrel locked to accommodate dynamic loads.

- Multi-material compatibility: Supports heterogeneous material combination connections.

- Good sealing: prevents liquid or gas leakage.

- Variety of materials: adapts to different environmental requirements

Cons of Monobolt Rivets

- Higher cost: complex manufacturing, higher price than ordinary blind rivets

- High demand for installation tools: special rivet guns are required.

- Non-removable: permanent connection after installation, cannot be easily replaced or reused.

Do You Have Any Questions?

Let Us Solve Your Problem

What is the Difference Between Magnalock and Monobolt?

| Magnalok Rivets | Monobolt Rivets | |

| Internal Locking Designs | The internal locking structure is inside and not visible to the naked eye. | You can see the internal locking structure |

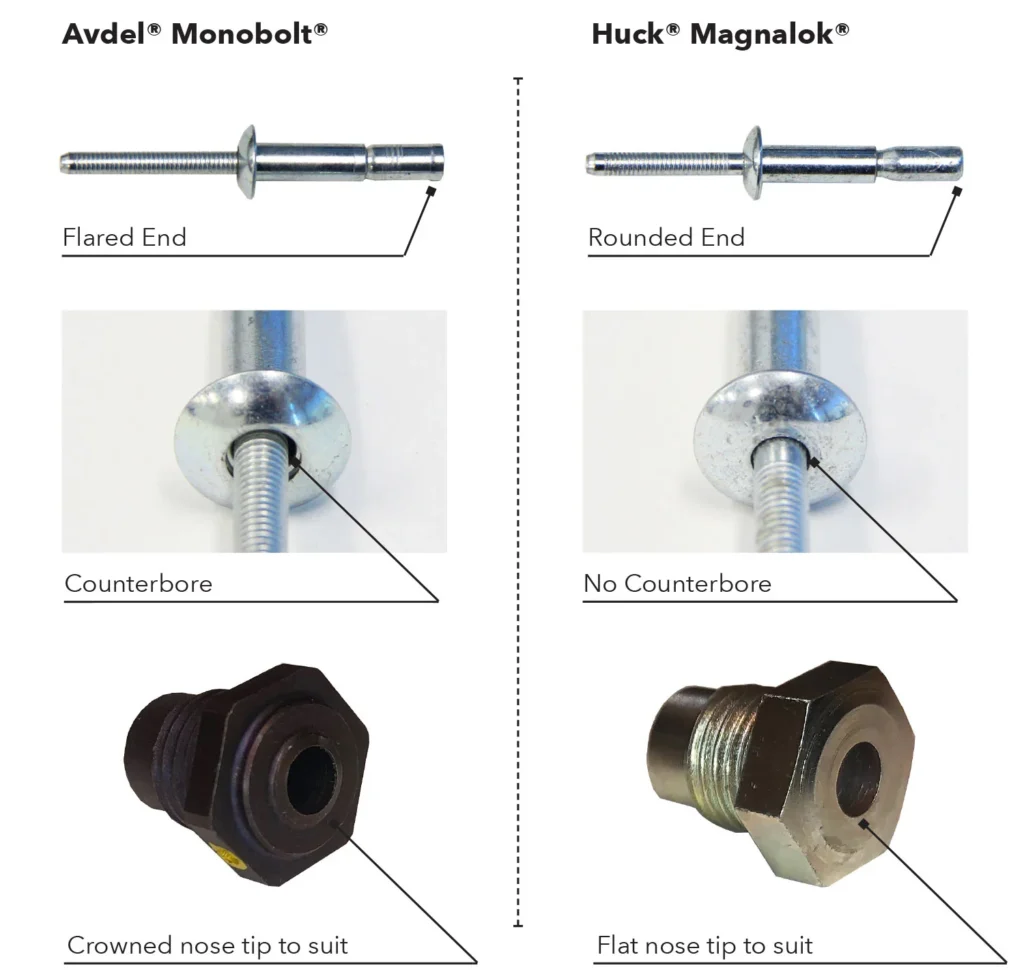

| Design | The head of the rivet body is rounded. Retracts inward | The head of the rivet body is square. Extends outward. |

| Country of use | Some countries only use the monobolt rivet and some only use the magnalok rivet. | |

| Service Life | Carrying 2 million loads | Carrying 100,000 loads |

Magnalok vs Monobolt: Internal Locking Designs

Magnalok rivets and monobolt rivets both have a locking mechanism on the inside, but they are different; the locking mechanism on monobolt rivets is directly visible to the naked eye.

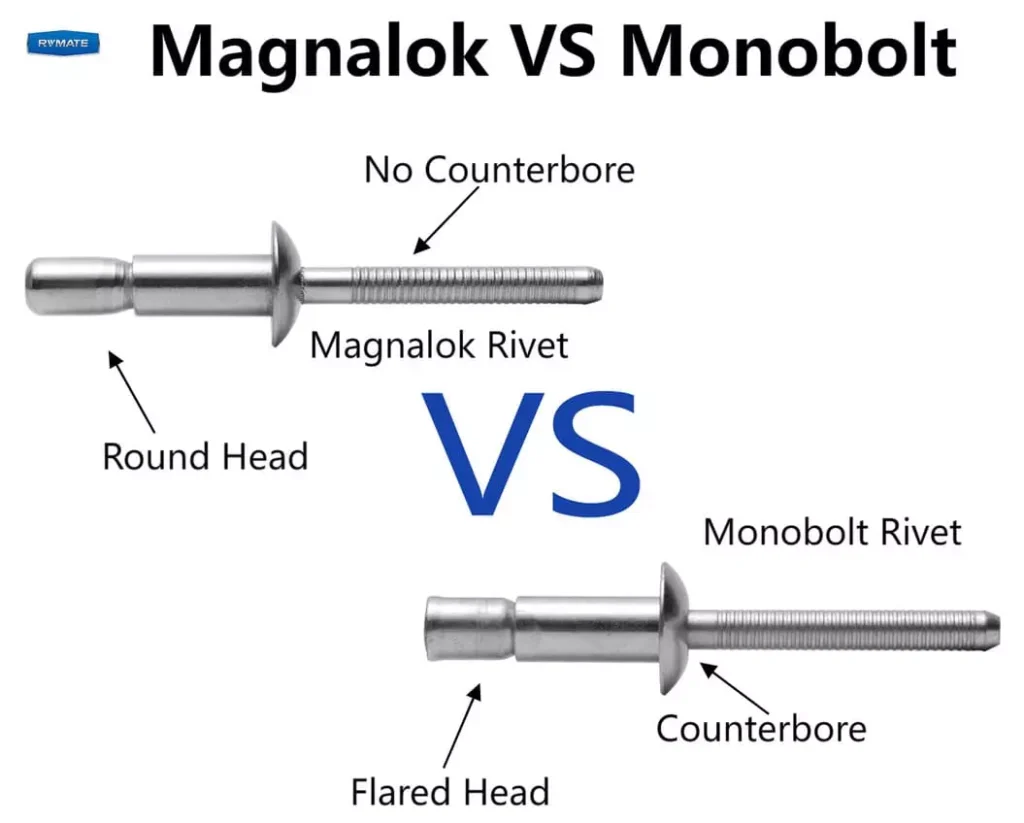

Magnalok vs Monobolt: Design

There is a significant difference in appearance between the magnalok rivet and the monobolt rivet. the end of the rivet body of the magnalok rivets curves inward, while the end of the monobolt rivets flares outward. the magnalok rivets have an inward curved end, while the monobolt rivets have an outward flared end.

Order Magnalok Rivets and Monobolt Rivets from Rivmate

In actual industrial manufacturing, magnalok rivets and monobolt rivets are used in a variety of structural joints. The Tesla Model S chassis uses a large number of high strength structural blind rivets.

Do you also need to use magnalok rivets or monobolt rivets for your project?Rivmate can provide you with high quality structural rivets and standard rivets. Buy directly from blind rivet manufacturer.

Get samples for testing now!