Table of Contents

A basic guide to understanding the 3 different types of rivet heads : types, differences, applications. How to choose the right types of rivet head for your project?

Table of Contents

Using the right rivet head is critical to the safety of your project. As one of the most important factors in choosing rivets, rivet heads can offer a variety of different specialized features for your project. Examples include waterproofing, dustproofing and reducing stress concentrations. The right rivet heads can help you get the job done. They ensure the tightest connection without harming the surface of the material. It makes riveting safe and stable.

In this article, we will reveal the three types of rivet heads and their various aspects.

What is a Rivet Head?

The Rivet Head is the part of the rivet that sits on top of the rivet. The Rivet Head is a key component used to provide mechanical lock and connection during rivet installation and fixing.

The primary purpose of the rivet head is to provide mechanical locking action while distributing the load. Different rivet head shapes and designs are suitable for different application scenarios and functional requirements. However, rivet heads are not not versatile, for example, LARGE FLANGE HEAD RIVET can be used in place of a DOME HEAD RIVET, and vice versa.

Engineers or rivet buyers usually choose the right rivet head according to their project requirements. If you know how to choose the right rivet head for your project, read on.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Different Types of Rivet Head

There are three common rivet head types on the market:

- Dome Head

- Countersunk Head

- Large Flange Head

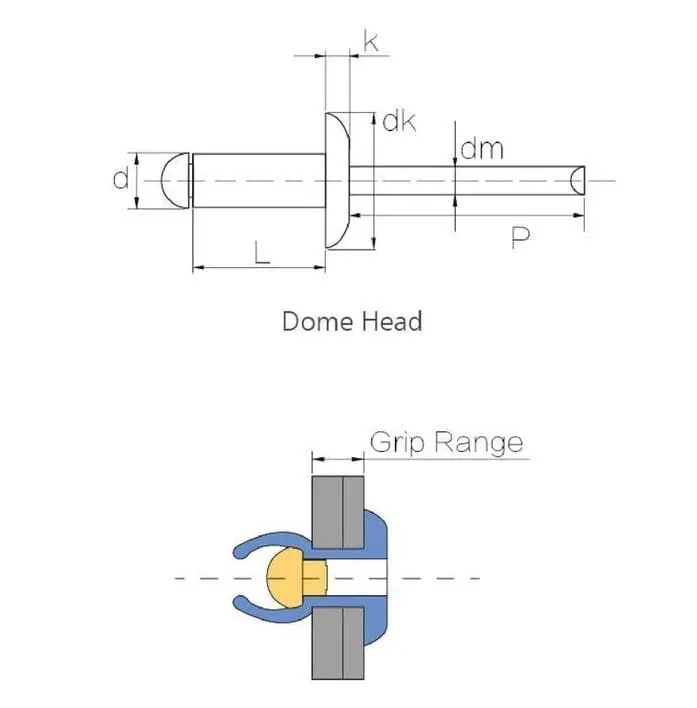

1.Dome Head Blind Rivet

Dome head blind rivets are a very common type of rivet head. It has a hemispherical head and is suitable for a variety of applications.

Dome head is also the most used type of rivet head. It provides a larger head contact area than a nail, spreading the pressure evenly. It can effectively prevent deformation or damage to the material. Of course, dome head blind rivet can make the connection part withstand higher shear force and tensile strength. This ensures that the connection remains stable and strong under high loads.

Applications of Dome Head Blind Rivet

You can see dome head blind rivets on many items and devices. Here are some common applications of dome head rivets:

- In the automotive industry, it is critical that fasteners can withstand body loads and vibrations.Dome head blind rivets can attach automotive body panels, interior trim and accessories.

- In electronic devices, their housings need a flat appearance, avoiding sharp corners and protrusions.Dome head can provide a strong mechanical fixing and a beautiful appearance.

- Builders need fasteners that provide a strong connection with sufficient stability and durability. Dome head provides good shear and tensile strength.

- Engineers use blind rivets when looking for ways to reduce the overall weight of an airplane, and these lightweight rivets ensure safe flight and structural stability while reducing weight.

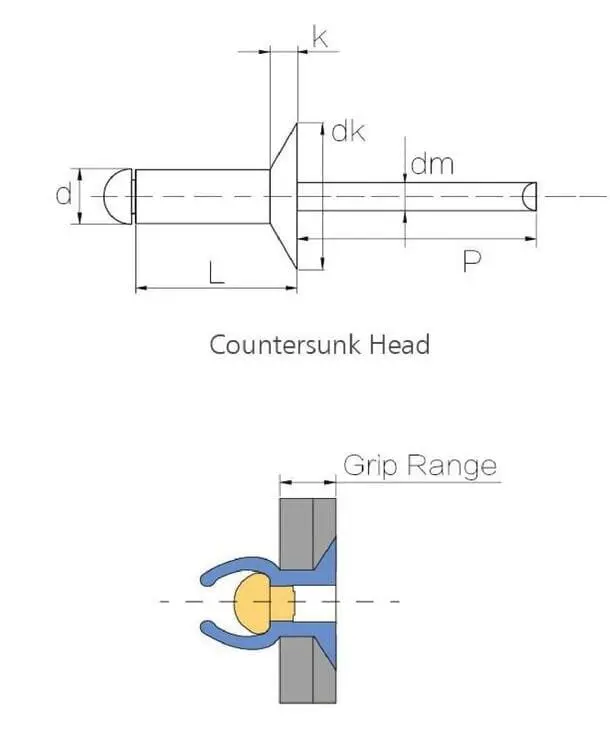

2.Countersunk Head Blind Rivet

The primary purpose of using Countersunk Head Rivet is to provide a smooth surface. And it allows the rivet head to be flush with or embedded in the material surface. This design is used to address specific mechanical and aesthetic needs.

In high-speed moving equipment or vehicles, protruding rivet heads can increase air resistance.Countersunk Blind Rivets provide an excellent solution to this problem. In mechanical or electronic equipment, protruding rivet heads may interfere with the operation or assembly of other components. Countersunk head rivets provide a flat surface that avoids interference and ensures proper operation and installation of other components.

Countersunk head rivets provide a smooth surface that reduces resistance to air or water flow, prevents interference and enhances aesthetics. This is why it is used in a wide range of applications such as aerospace, automotive manufacturing, electronic equipment, furniture manufacturing, construction and decoration, as well as marine and offshore engineering.

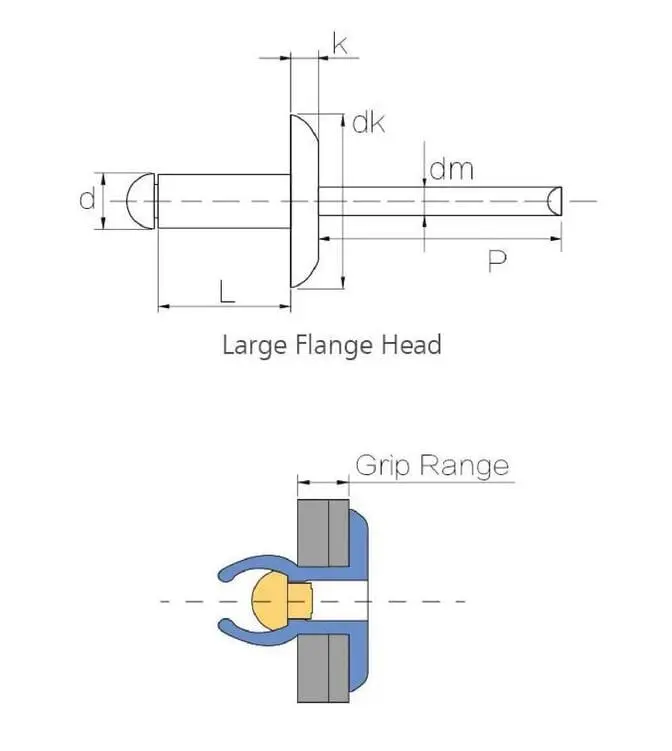

3.Large Flange Head Blind Rivet

The primary purpose of using Large Flange Head Rivet is to provide a larger contact area to spread the load and prevent material damage, especially when joining soft or thin materials. Most metal rivets have no way of joining soft materials. But Large flange head blind rivet provides a good solution for this.

Large flange head blind rivets are not only suitable for joining soft or brittle materials. Large flange head blind rivets are not only suitable for joining soft or brittle materials, but also provide greater tensile strength than dome head blind rivets, and the design of the large flange head prevents the material from tearing at the edges.

Applications of Large Flange Head Blind Rivet

Here are some common applications for large flange head blind rivet:

- Large flange head blind rivets can be used for metal roof and wall panel connections. They prevent tearing and deformation caused by wind and other external forces.

- This type of rivet is also used for thinner household appliance housings and internal component connections. Prevents damage and loosening during use.

- It is also used to join sheets and conforming materials in furniture manufacturing. It is effective in preventing material tearing and damage.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Factors to Consider when Choosing Different Types of Rivet Heads

Here are some factors to consider when choosing the right different types of rivet heads patterns for your project.

1.Characterization of Materials

There are many different types of materials being joined (e.g., metals, plastics, composites, etc.). Different materials affect the choice of rivet head type. For example, soft materials typically require a larger contact area to spread the load, so a large flange head rivet is more suitable.

The thickness of the material determines the suitability of the rivet head. Thick materials are usually suitable for dome head rivets and countersunk head rivets, while thin materials are suitable for large flange head rivets to prevent deformation and damage.

2.Load and Strength Requirements

Different head types of rivets perform differently in terms of tensile and shear strength. If your project requires a high level of strength, all three types of rivets are available. This is the time to use high strength structural rivets.

If you need to spread the load to prevent stress concentrations, large flange head rivets provide a larger contact area, reducing material damage.

3.Appearance and Aesthetic Requirements

If your customers have high aesthetic demands (e.g., furniture manufacturing and household appliances), choosing a countersunk head rivet head pattern with a decorative effect will maintain the overall appearance.

For applications that require a smooth surface (such as electronic equipment and high-end furniture), countersunk head rivets provide a flat surface that prevents the rivet head from protruding.

4.Application Scenarios

- Construction and Infrastructure: Connections requiring high strength and durability are often made with large flange head rivets or structural rivets.

- Automotive: The connection of body panels and interior trim requires countersunk head rivets or large flange head rivets to ensure flat surfaces and high strength connections.

- Aerospace: Countersunk head rivets and structural rivets are common choices for lightweight and high-strength structural connections.

- Electronic equipment: housing and component connections require smooth surfaces and reliable fastening, choose countersunk head blind rivets.

Conclusion

Understanding the different types of rivet heads is critical to ensuring the quality and safety of your project. Whether your project is for thin sheet joining, automotive structural joining or soft material joining. The three different types of rivet heads listed above will meet your needs. So, after learning the basics of rivet heads, invest in a reliable rivet for your riveting project.

Get Great Riveting Solution with Rivmate

Rivmate offers all types of rivets and rivet solutions. Their high quality and durable products are available for all your riveting needs. Request an instant quote and our team of experts will help you select the perfect rivets for your project.