Dome Head Blind Rivets

What is blind rivet?

Blind rivets are suitable for situations where double-sided riveting is not convenient. Specialized tools (Electric/Pneumatic blind rivet riveting gun) are required for riveting.

The blind rivets are pulled with a special riveting gun when riveted, and the riveting body expands and never reaches the riveting effect. Widely used in construction, automobiles, airplanes, machines, electrical appliances, furniture and other products.

RIVMATE Blind Rivet

Rivmate is top blind rivet and rivet nut manufacturer in china.It is IATF 16949:2016 manufacturer.The factory can provide dome rivets, countersunk head rivets, large flange rivets.

Mainly provide standard rivets, structural rivets, high strength rivets.

Appliance:Buildings, cars, ships, planes, machines, appliances, furniture

Specificities: Favorable • versatile • high strength • secure

Rivet Body

Aluminum – Lightweight, good corrosion resistance

Carbon Steel – High strength material, high hardness

Stainless Steel – High strength, high hardness, general corrosion resistance

Steel – Very strong, high strength, low corrosion resistance

Copper – Good electrical conductivity and corrosion resistance

RIVMATE Dome Head Rivet

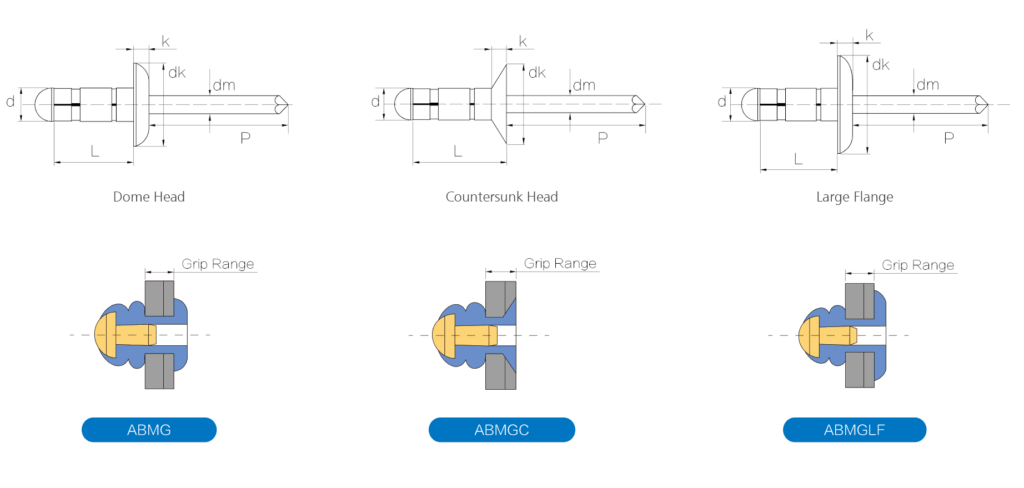

Blind Rivets are available in a variety of head styles.The most commonly used are dome head, countersunk head, large flange head.

Available in a variety of materials.

It applies to most application scenarios.

The most widely used blind rivets due to their low cost of use.

Dome Rivets

The head of a dome head rivet is much larger than the diameter of the nail body, providing enough contact area to avoid the possibility of material damage. Dome head rivets are also the most commonly used type of rivets and can be applied in a variety of scenarios

Available in many material combinations.

Aluminum:

Aluminum – Carbon steel :Inexpensive and good process performance. Generally used in engineering structures and general mechanical parts

Aluminum – Aluminum :It is the lightest in weight and is mostly used in the aerospace industry. Not very strong, you need to plan and consider it yourself before application

Aluminum – Stainless steel :Good corrosion resistance, high strength, very many application scenarios, can be applied to the strength and quality requirements of the scene

Aluminum – Steel :Inexpensive and lightweight rivets. Average strength, used in scenarios that don’t require much strength

Steel:

Steel – Steel :Not too costly and good strength. But more prone to corrosion

Stanless Steel – Stainless Steel:Strong corrosion resistance, high strength rivets. Installation requires more specialized installation tools and is more expensive

Carbon Steel -Carbon Steel:Easier to install and relatively low cost

Stainless Steel 304/420:Strong corrosion resistance, high strength rivets. Installation requires more specialized installation tools and is more expensive

copper:

Copper – Steel:It is mainly applied to scenarios that require conducting electricity

Download Rivmate Bind Rivet Brochure 2023

Purchase a product or request a quote

You can ask us for a quote.Drawings can also be provided to customize rivets for your project

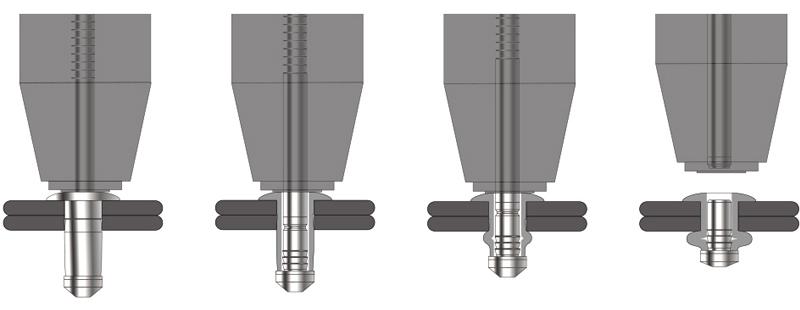

How to insall blind rivet ?

To install a blind rivet, you first need a professional tool, which can be manual, electric, or pneumatic, and there are many riveting tools to choose from. Below I will use a pneumatic riveting gun as an example to illustrate, the body of the rivet into the riveting tool, and then use the pneumatic riveting gun to pull the rivet, the rivet breaks, the head of the rivet is squeezed, and the two pieces of thin boards are tightly connected together. The picture above demonstrates the riveting process.

Application scenarios of dome head blind rivets

There are many application scenarios for blind rivets. Basically every field will use the blind rivets. But the blind rivets are also divided into many kinds, according to the different application scenarios to choose different kinds of blind rivets. There is no omnipotent fastener, only the fastener that suits you!

In automotive design, blind rivets are commonly used in door sill beams, battery mounting, seat beams to realize the connection to the seat, but also in the body, door area, and can realize the connection inside the hood.

In the maintenance of the time, pivot rivets will also be frequently used, pivot rivets is a major feature is that it can be unidirectional riveting, to solve the maintenance of the difficult point!

The biggest point of the Blind Rivet is that it can provide strong connection strength and can be riveted unilaterally, which greatly facilitates the difficulty of repairing, engineering and other connections.

The process is very simple, can be achieved by connecting two parts do not need molds, and there are many types of blind rivets, different types of applications of different scenarios, so we are in the choice of blind rivets, we should give full consideration to the use of our project scenarios. Suitable rivets in order to play the greatest role.

If you have product needs or questions, please feel free to contact us and we will provide the most secure connection for your project.