Table of Contents

Expansion is an important indicator of the quality of the connection of a blind rivet. So How Much Do Rivets Expand? Let’s find out together!

Table of Contents

What is the Rivets Expand?

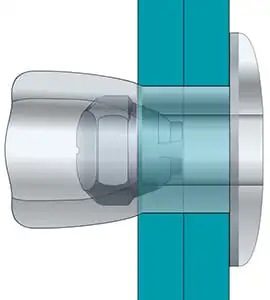

The expansion rate of a blind rivet, also known as the expansion rate or expansion ratio, is the degree to which the tail of the rivet expands and deforms in the hole due to the pull of the mandrel during installation. This parameter expresses the percentage increase in the diameter of the rivet from its initial state after insertion into the hole to when it is fully installed. A satisfactory rate of expansion ensures that the rivet will fill the hole securely and provide a stable mechanical connection.

Expansion Ratio is the ratio of the diameter of the expanded portion of the rivet after installation to its original diameter. It can be expressed as:

Expansion Rate = Diameter After Expansion / Original Diameter

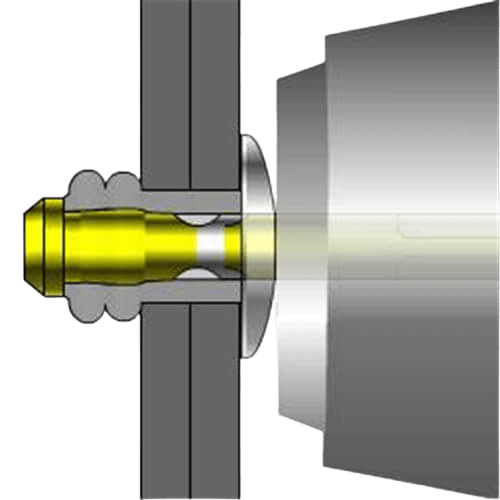

Illustrative Example

Suppose a rivet has an initial diameter of 4.0 mm and after installation it expands to a diameter of 6.0 mm:

Expansion Rate = 6.0mm / 4.0mm = 1.5

The expansion rate of a blind rivet is a key parameter that measures the degree of deformation and expansion of the rivet during installation. The correct rate of expansion provides a strong mechanical connection, prevents loosening, distributes stresses and enhances strength. Therefore, selecting and controlling the proper expansion rate is critical to ensuring the quality and reliability of the connection.

Why is the Expansion Rate of Blind Rivets so Important?

The expansion rate of a blind rivet plays a critical role in the joining process. Correct selection and control of the rivet’s expansion rate ensures that the rivet deforms and expands correctly during installation, thus providing a reliable mechanical connection, preventing loosening and material damage, and improving the quality and durability of the overall connection.

Below are a few areas detailing their primary role:

1. Ensure Tight Fixing

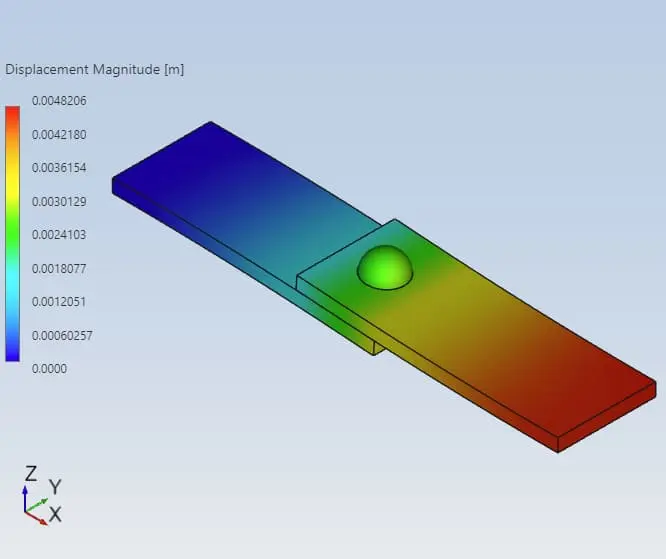

The proper expansion rate allows the rivet to expand sufficiently in the hole to tightly secure the joining material. The expanded rivet completely fills the hole, providing a strong mechanical connection. And it effectively prevents the connection from loosening under vibration or dynamic loading

2. Dispersion of Stresses

Expanded rivets increase the contact area with the hole wall, thereby spreading the stresses applied to the joint. This reduces stress concentration and prevents material rupture or damage.

If you your project materials are softer or more brittle, the proper rate of expansion can effectively disperse the stresses and prevent rupture of these materials due to excessive stress concentrations.

3. Enhanced Shear and Pull-out Strengths

A rivet with a moderate expansion rate provides a larger shear area, which enhances the ability of the joint to resist lateral loads.

The higher the expansion rate, the greater the contact area between the rivet and the hole wall. The pull-out strength of the rivet increases accordingly. The proper expansion ratio can effectively prevent the rivet from coming out under axial load.

4. Adaptation to a Wide Range of Materials

Appropriate expansion ratio enables rivets to adapt to a variety of types of materials, such as metals, plastics, composites, etc., to ensure a good connection on a variety of materials.

5. Reduced Rework and Maintenance

The correct expansion rate ensures that rivets are installed successfully in a single pass. It can help reduce rework and maintenance costs due to connection failure.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Prons and Cons of High Expansion Rate of Blind Rivets

The expansion ratio of blind rivets plays a key role in the connection process, affecting the strength and stability of the connection. Different expansion rates have their advantages and disadvantages, the following are the advantages and disadvantages of high expansion rate and low expansion rate:

Prons

- Larger contact area: High expansion rate increases the contact area between the rivet and the hole wall, enhancing friction and fixing force.

- Stress Dispersion: High expansion rates provide better dispersion of stresses and reduce stress concentrations. It can effectively reduce the risk of material rupture or damage, especially for softer or more brittle materials.

- Higher Tensile and Shear Strength: Expanded rivets provide higher tensile and shear strength. Ideal for applications where higher or dynamic loads need to be applied.

- Suitable for thinner or softer materials: High expansion rivets form strong joints in thin or soft materials.

Cons

- Risk of material damage: In harder or thicker materials, excessive expansion rates may result in material damage.

- Difficulty of installation: Higher installation forces and precision are required to achieve proper expansion. Adds complexity and time to the installation process.

Prons and Cons of Low Expansion Rate of Blind Rivets

Prons

- For thicker or harder materials: the lower expansion creates sufficient holding power in thicker or harder materials. This ensures that these materials are not damaged by over-expansion.

- Ease of installation: Lower expansion rates usually require less installation force and less precision. The installation process is easier and faster.

Cons

- Lower contact area: Lower expansion reduces the contact area between the rivet and the hole wall. May result in loose connections, especially in high vibration or dynamic load environments.

- Concentration of stress: Rivets with low expansion ratios may not be able to effectively distribute stress.

Stress is concentrated at the edge of the hole, increasing the risk of material rupture or damage, especially in more brittle materials. - Lower Tensile and Shear Strengths: Low expansion rivets provide lower tensile and shear strengths due to the smaller contact area.

How to Choose The Right Expand of Rivets

Ⅰ. Understanding Expansion Rates

Before making a choice on the expansion rate of a rivet, you need to understand what expansion rate is. You can get the answer by contacting us or checking the web.

Ⅱ . Consideration of Material Properties

After understanding the basic definition of expansion rate, you need to have your own judgement on what kind of expansion rate corresponds to different materials.

Softer or more brittle materials (such as plastics or thin metal sheets) usually require a higher expansion rate to increase the contact area to spread the stresses and prevent the material from rupturing.

Ⅲ . Load Requirements

The final point to consider is the load requirement. You need to choose the appropriate rivet expansion rate based on the load the connection needs to withstand. Higher expansion rates usually provide higher pullout and shear forces.

And in vibrating environments, a higher expansion rate helps increase stability.

Conclusion

There isn’t really a universal standard value for rivet expansion. This value will vary depending on the specific application scenario, the characteristics of the joining material and the loads to be carried. However, in general, an expansion rate of between 1.5x and 2x is considered to be an appropriate range for rivets. Expansion rates in this range provide adequate holding power and reliability in most applications.

Get Blind Rivets from China Rivets Factory

Rivmate is one of the top China Blind Rivet manufacturers and suppliers, if you need to buy Blind Rivet, you can contact us!

We can customise the blind rivets and expansion rate according to your project needs. If you need to order blind rivets, get a quote now.