How Strong are Rivet Nuts

Rivet Nuts are a powerful solution for riveting fastening. Rivet nuts offer many features such as being suitable for single sided riveting, easy to insert, affordable and convenient. These benefits have made them widely popular in manufacturing processes around the world.

Rivet nuts are one of the most common fasteners used by engineers, but their benefits are usually significant in their application. In this piece of writing, we’ll take an in-depth look at how rivet nuts are constructed, how they work, how they differ from other connection methods, and the strength they can provide.

Table of Contents

What is a Rivet Nut?

In order to solve the thin metal plate, thin tube welding nut easy to melt, easy to weld the base material deformation, tapping internal threads easy to slip teeth and other issues, engineers invented the rivet nut this fastener products. The use of rivet nuts do not need to attack the internal threads, do not need to weld the nut, riveted firmly, high efficiency, the use is also very convenient.

How do Rivet Nuts Work?

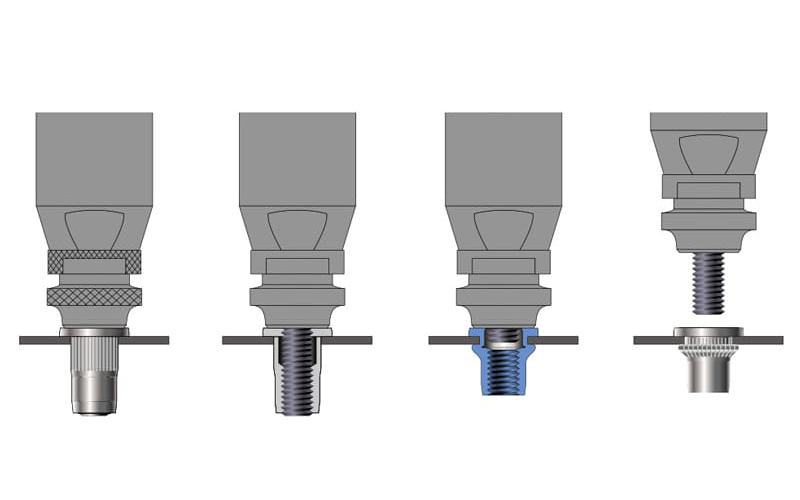

The working principle of the rivet nut can be said to be a combination of core-pulling rivets and welded nuts, through the rivet gun above the screw to pull the rivet nut, the rivet nut will be compressed longitudinally, in the end of the surface caused by the raised deformation, so as to clamp the riveted object to achieve riveting effect.

Strength Assessment of Rivet Nuts

How can I tell if a Rivet nut is strong or weak? Professional rivet nut testing is usually performed through tensile and shear tests. The youbute video above shows the entire process of rivet nut strength testing in Rivmate’s testing lab. Below is a description of these two test methods and how to determine the strength of a rivet nut based on the test results:

- Tensile Test: The tensile test is primarily used to evaluate the strength and load carrying capacity of a rivet nut under tensile loading. During the test, the rivet nut is usually secured in a fixture and then stretched by applying a tensile force to it until it reaches the breaking point. The test results will provide the tensile strength and maximum load carrying capacity of the rivet nut.

- Shear Test: The shear test is used to evaluate the strength and load carrying capacity of the rivet nut under shear loading. During the test, the drivet nut is usually secured in a fixture and then sheared by applying a shear force until the point of destruction is reached. The test results will provide the shear strength and maximum load carrying capacity of the drivet nut.

How to Determine the Strength of Rivet Nuts?

If your company has a specialized laboratory for testing rivet nut, then you can easily obtain the tensile and shear strength of rivet nut. Based on the test results of the tensile and shear tests, you can well evaluate the strength and load bearing capacity of the rivet nut. Generally speaking, you need to pay attention to the following aspects to judge the strength of a rivet nut:

Damage Mode

The damage pattern of a rivet nut can provide information about its strength and load carrying capacity. For example, in a tensile test, if the tensile section of a drivet nut is the rod portion, the strength depends mainly on the material and size of the rod. In the shear test, if the damage of the rivet nut occurs at the contact between the thread and the rod, it means that the strength is mainly determined by the thread load carrying capacity.

Analysis of Test Results

Analysis of test results: Based on the test results of the tensile and shear tests, the destructive load and maximum load carrying capacity of the rivet nut can be obtained. These data can be compared with the load requirements of the application. The strength and compliance of the rivet nut can be evaluated.

Material Selection

It is well known that the difference in strength between different metal materials is significant. For example, steel is much stronger than aluminum. So the strength and load carrying capacity of a drivet nut is closely related to its material. But the material of the rivet nut is chosen according to its actual application. A suitable material is essential to ensure that the rivet nut meets the requirements of the application.

How Strong are Rivet Nuts?

There are many factors that affect the strength of a rivet nut. Even for the same type of rivet nut, the strength varies greatly depending on the material used. Below I will provide a comprehensive explanation of the factors that affect the strength of rivet nuts.

Difference in Strength of Materials

There are many metals that can be used as raw materials for the rivet nut. Common rivet nut materials include aluminum alloys, steel and stainless steel. Different materials have different strength and mechanical properties. Their strengths in descending order are: steel > stainless steel > aluminum.

Comparison of Rivet Nuts and Other Connection Methods

Rivet Nut vs Bolt

A bolt is a very strong joint fastener. In contrast to the bolt, the rivet nut can provide very reliable strength and load carrying capacity. As long as you purchase the correct specification and material for the drivet nut, you can get a reliable fastener that meets the strength requirements of your project. Compared to bolts, the rivet nut has a higher load carrying capacity under tension loads and is less likely to loosen.

The rivet nut can be installed on one side. So when you have limited space, the rivet nut is an excellent solution.

The rivet nut does not leave a raised head or weld marks like a bolt, and the rivet nut is much cleaner and more aesthetically pleasing to the eye.

Rivet Nut vs Weld

The installation of the rivet nut is very easy compared to conventional welded connections. Typically, engineers only need to use the appropriate tools to install the rivet nut to the material to be connected, without the need for complex equipment and specialized skills. So it is more convenient when you are on site for rivet nut installation, maintenance and dismantling.

Welded connections often damage the surface of the raw material when joining non-metallic materials, causing damage or deformation. This is not the case with rivet nut. It is suitable for different kinds of materials, both metallic and non-metallic, such as plastics and composites.

Rivmate can Provide you with High-Strength Rivet Nuts

Are you ready to secure your project with high strength rivet nuts? Based on the information in this guide, you are fully aware of how strong are rivet nut. but where can you buy the best rivet nut?

At Rivmate, we offer a wide range of high quality and high strength rivet nut solutions. Meet the needs of your project. From material, type of design, we have everything you need. Explore our OEM service options for customized rivet nut solutions, or contact us to learn more about rivet nuts.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com