Table of Contents

gutters are an important part of the building. For builders, the best way to secure gutters is a question that needs to be well considered. This guide will show you all about blind rivets for gutters. Including the advantages, how to choose gutters rivets.

Table of Contents

Role of Gutters

In the field of construction, gutters are a very common component. Its role is mainly to collect and channelize rainwater, thus protecting the structure and foundation of the building from water damage.

In fact gutters do much more than that, its main roles are as follows:

- Preventing damage to the foundation: Gutters direct rainwater away from the roof to a specific drainage area, preventing it from flowing directly near the foundation of the building.

- Preventing damage to roofs and walls: Gutters prevent rainwater from flowing directly from the roof to the walls, preventing the walls from becoming damp or spalling.

- Protects against landscape and soil erosion: by directing rainwater away from buildings. Without proper drainage, rainwater can wash away surface soils, causing vegetation to be washed away or the ground to sink.

- Prevents gutter overflow and ponding problems: Properly installed and maintained gutters prevent roof gutters from ponding or overflowing, ensuring smooth water flow and preventing rainwater from building up on the roof and causing increased pressure.

Characteristics to Note When Installing Fasteners for Gutters

For a building, gutters are a very important part. That’s why it’s necessary to hold it stable and long-lasting. Then it is vital to choose a proper fastener for this job. These fasteners need to ensure that the gutters system is solid, secure and able to withstand different environmental conditions.Let’s read on!

Corrosion Resistance

Because gutters are exposed to the open air for long periods of time, they need to withstand rain. Therefore, fasteners should be corrosion-resistant, especially when exposed to rain and moisture for long periods of time in outdoor environments. Commonly used corrosion-resistant materials include stainless steel, galvanized steel and copper.

A fastener that will not rust or lose strength in a wet environment can greatly extend the life of a gutter system.

High Strength

Gutters are typically set up against building walls and they are required to withstand pressure from rainwater during rainy weather. That’s why qualified gutter fasteners should be strong enough to support the gutters, especially during heavy rain or snow, when the load on the gutters can increase significantly.

If the fasteners are not strong enough, the gutters may sag, fall off, or even pose a safety hazard.

Wind Resistance

In windy areas, fasteners should be able to ensure that the gutter system will not loosen or shift during windy weather. Select fastener types that are designed to be more robust.

Ease of Installation

During the actual installation, fasteners should ensure that the gutter system can be installed quickly and efficiently.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Why Using Blind Rivets for Gutters?

Above we described the features that should be present in fasteners that secure gutters. Next I will show the advantages of gutters rivets.Blind rivets for gutters are the most commonly used connection.

1. Easy Installation with One-sided Operation

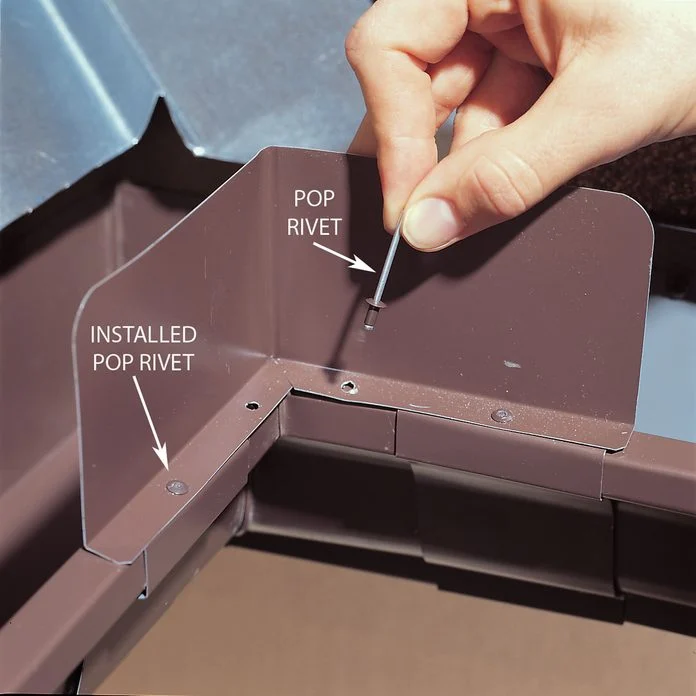

One of the biggest advantages of the blind rivet is that it allows installation to be accomplished by a single-sided operation. This means that when installing gutters, workers only need to work from the outside of the gutter and do not need to touch the back side.

While it is well known that gutter installations often need to be under the eaves of a building or in confined areas where the use of screws may be inconvenient, blind rivets can significantly simplify the installation process and increase construction efficiency.

2. Provides Strong and Durable Connection

Blind rivets are permanent connections. Once installed, the end of the rivet body expands, firmly securing the joint of the gutter. This mechanical connection is stronger than screws or nails, even under vibration or external stresses (e.g. wind, snow loads).

3. High Corrosion Resistance

There are many materials used to manufacture blind rivets. Among them gutters rivets are usually made of stainless steel, aluminum or galvanized steel materials. These types of materials gutters rivets have good corrosion resistance.

Gutter systems are typically exposed to the outdoors for long periods of time, and corrosion-resistant rivets can prevent connection failures due to rust or corrosion.

4.Vibration and Wind Stability

The fixing of the blind rivets is permanent and is very strong and stable.Gutters are often subjected to strong winds or heavy rainfall, but blind rivets are able to resist the effects of vibration and wind, and the joints remain stable and do not loosen or fall off.

So if your gutters project is in an area with strong winds or in a high-rise building, the use of blind rivets can provide a higher level of security for your gutters.

5. Protection Against Water Leakage

Because blind rivets fully expand and fill holes after installation, they create a tight seal compared to screws or bolts, preventing rainwater from leaking through the joints.

6.High Durability and Low Maintenance Requirements

Blind Rivets have a feature that no other fastener has. Once installed, they require little maintenance. They do not loosen or corrode as easily as screws and therefore remain strong for long periods of time.

For systems such as gutters that are exposed to the elements for long periods of time, the use of durable blind rivets reduces the cost and effort of post-maintenance.

How to Choose Blind Rivets for Gutters?

I’m sure many building contractors have questions about “how to choose blind rivets for gutters”. If you don’t know how to choose the right gutters rivet for your project, then you need to read the next content carefully. Selecting the right blind rivets for gutters requires consideration of material, size, environmental durability, and installation needs. Below are the key factors to consider when specifically picking a blind rivet:

Choosing the Right Material

Construction gutters need to withstand high levels of strength and require high corrosion resistance from the connecting blind rivets. Therefore, gutters rivets should choose aluminum blind rivets or stainless steel blind rivets, both of which are very suitable for outdoor environment.

Of course, if you have a limited budget for your project, galvanized steel blind rivets are also a good choice.

Consider the Size of the Rivet

A common rivet diameter of 3/16 inch (approximately 4.8 mm) is suitable for most gutter connections. If a higher load capacity is required, a larger diameter rivet can be selected.

As a builder, you need to make sure that you choose a rivet diameter that matches the thickness of the gutter material to avoid rivets that are too thin or too thick to affect the strength of the connection.

In addition to this, the length of the rivet should be 1.5 to 2 times the thickness of the material being secured.

Consider the Load Capacity of the Rivet

Gutter systems may be subjected to strong wind or snow loads, so rivets should have adequate load capacity. Typically, larger rivet diameters and suitable materials provide higher tensile and shear strengths.

Balancing Aesthetics

The gutter system is located on the exterior of the building, so the color and aesthetics of the rivets are also important. You can choose colored rivets that match the color of the gutters to maintain a uniform building appearance.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Frequently Asked Questions

Q:Why Use Blind Rivets Instead of Screws to Install Gutters?

Blind rivets are suitable for one-sided operation, facilitating gutter installations in confined spaces or where access to the backside is difficult. The expanded structure of the rivet provides a stronger connection that is less likely to loosen or fall off, making it suitable for structures that are exposed to the outdoors for long periods of time.

When installing, the spacing between rivets should normally be maintained between 18 and 24 inches (45-60 cm) to ensure stability and uniform load bearing capacity of the gutters. Too wide a spacing may result in sagging or uneven forces in the center of the gutter.

Q:Can Blind Rivets be Removed and Replaced?

Blind rivets are permanently attached. Once a blind rivet has been installed, removal of the rivet requires the use of an electric drill to drill through the head of the rivet. Once removed, the rivet can be replaced with a new one, but it will not be as easy to remove and reuse as a screw.

Conclusion

Are you looking for reliable blind rivets for your gutters project? Contact us today! We will provide you with gutters rivets solutions!