How to Install Pop Rivets ? - The Most Complete Guide

Table of Contents

In industrial assembly and sheet metal fabrication, pop rivets represent one of the swiftest, most dependable, and cost-effective fastening solutions available. How to install pop rivets?

Though the installation method appears straightforward, it directly impacts joint strength, waterproofing performance, and long-term stability. Consequently, mastering the correct installation procedure for pop rivets constitutes an essential foundational skill for any engineer engaged in sheet metal work, HVAC systems, domestic appliances, vehicle modifications, or outdoor structural assembly. This guide systematically explains the entire process from selection to installation from an engineer’s perspective, enabling you to install rivets correctly the first time and avoid issues such as loosening, water ingress, or failed riveting. Rivmate also provides professional, practical advice tailored to different applications.

What Are Pop Rivets?

Pop rivets can also be called Blind rivets. it was designed to be able to cater for single side mounted applications.

Originally used in aircraft manufacturing and invented by Hamilton N. Wylie in England, Pop rivets are now used in everything from aircraft and automotive manufacturing to the assembly of various electronic products due to their quick and easy installation and the ability to be mechanized on a large scale.

Pop rivets consist of two parts, the rivet body and the mandrel. During installation, the mandrel is pulled off and embedded in the rivet body, thus realizing a stable connection.

Types of Pop Rivets

Since pop rivets were invented, they have evolved and there are now many, many types of pop rivets. And pop rivets have now become the number one choice for sheet metal connections. Different types of rivets are made of different materials and they are applied in different scenarios. Below I will list the most common types of pop rivets and introduce the corresponding application scenarios:

Open Type Blind Rivets

Open end blind rivets are the most common type of blind rivets and the ones used in the largest quantities. It is characterized by leaving an open hole after installation. It is often used in scenarios such as the housing of appliances, the attachment of furniture and the connection of electronic devices.

Sealed Type Blind Rivets:

Sealed Blind Rivet is a specially designed blind rivet. It has a closed end of the rivet body to form a sealed structure. In addition to providing a good connection, it also prevents liquids and gases from entering the connection area. It is often used in automobile exhaust systems, waterproof connections in roofs and furniture that needs to be waterproof such as washing machines.

Peel Type Blind Rivets

Peel type blind rivets are blind rivets specifically designed to join soft and brittle materials such as plastics, wood and composites. Its unique design creates multiple petal-shaped clamping areas, providing a larger contact area and more uniform clamping force.Peel rivets are ideal for use in plastic shells, soft wood joints and composite joints.

Multi grip blind rivets

Multi-Grip Blind Rivets can accommodate a wide range of material thicknesses, reducing inventory requirements and simplifying the selection process.Multi-Grip Blind Rivets provide reliable clamping force and joint strength over a wide range of material thicknesses during installation. It is used in a wide range of applications, including automotive body connections, aircraft repair, structural steel connections, marine and equipment fastening.

Monobolt Rivet

The Monobolt rivet is a high strength structural rivet designed for use in connection applications where high strength and reliability are required. It has a unique locking mandrel design that ensures the rivet will not loosen after installation and will remain stable in high stress and high vibration environments. It will be used in applications where high strength is required. For example, automotive chassis, steel structures, railroad body connections and heavy machinery connections.

Exploding pop rivets

Exploding pop rivets are specially designed blind rivets with unique expansion and locking characteristics that allow them to be installed with a large diameter “bulb” shaped expansion body to provide greater clamping force and better load distribution. These rivets are particularly suitable for joining soft and thin materials such as plastics, composites and sheet metal.

What You Need Before Installing Pop Rivets ?

① Pop Rivets

You need to choose the appropriate type of rivet for the application in advance, including:

- Open-End Blind Rivets: The most commonly used type, with the lowest cost, suitable for general sheet metal.

- Closed-End Blind Rivets: Used for waterproofing and airtightness, commonly applied in roofing and outdoor structures.

- Structural Rivets (such as Monobolt): Used in high-load and high-vibration conditions.

Before choosing rivets, make sure to confirm the Grip Range. An incorrect Grip Range will result in riveting failure – too short to hold firmly or too long for incomplete forming.

② Drill & Drill Bits

The size of the hole directly determines whether the rivet can expand correctly.

- Generally, it should be 0.1–0.2 mm larger than the diameter of the rivet.

- If the hole is too large → the rivet will become loose.

- If the hole is too small → the rivet cannot be inserted or will be overly compressed.

Use metal-specific drill bits and keep the holes drilled vertically to avoid oval holes that may lead to a decrease in strength.

③ Deburring Tool

After drilling, deburring is essential. Burrs can affect the mating surface of the rivet and the clamping force. Many failed riveting operations are due to the fact that “deburring was not done”.

④ Rivet Gun

Choose the production volume and rivet type that suit you:

- Manual Rivet Gun: Suitable for DIY and small-scale use.

- Pneumatic Rivet Gun: Fast speed, suitable for factory production.

- Battery Rivet Gun: Portable and highly efficient, used in construction sites.

- Heavy-Duty Rivet Gun: Necessary for installing structural rivets (Monobolt, T-Rivet).

Structural rivets require a higher tensile strength, which is generally beyond the capacity of manual tools.

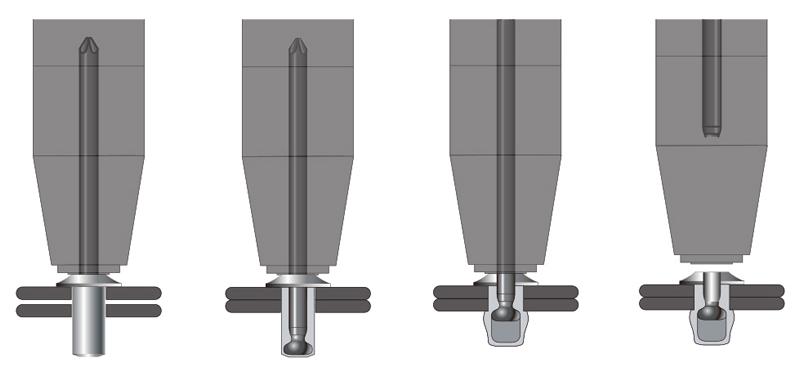

How Pop Rivets Work ?

a. Core shaft pulls the cap body, causing the rivet to expand and lock on the reverse side.

The core structure of a Pop Rivet consists of two parts: the rivet body and the mandrel. When the riveting gun starts to apply force, the thickened part of the mandrel will pull the tail end of the rivet body forward, causing it to expand on the backside of the material. The expanded tail end spreads out like a “mushroom”, firmly clamping the two thin plates together. This is the fundamental reason why Pop Rivets can form reliable connections on thin plate structures.

b. The mandrel fractures but remains partially intact, continuing to provide clamping force.

Upon completion of the expansion action, the mandrel fractures at the predetermined fracture groove location. The front section of the fractured mandrel remains within the cap body, serving to maintain the rivet’s shape and provide internal support. This residual mandrel prevents a reduction in clamping force and enhances overall tensile strength. Many users are unaware that mandrel retention is a critical design feature ensuring the strength stability of blind rivets, rather than a “residual defect”.

c. Why can Pop Rivets be installed from one side only?

Pop Rivet, also known as Blind Rivet, is so named because it can be installed in “blind areas”, that is, riveting can still be completed when the back of the structure is inaccessible to the installer. The reason is very simple: all the force application processes occur on the front side, and no manual support or tool application is required on the back. The expansion on the back is automatically completed internally, thus no additional equipment or space is needed. This feature makes blind rivets extremely common in applications such as chassis and cabinet, appliance shells, vehicle interior trims, and profile cavity.

Summary of the Pop Rivet Working Process

The installation process can be briefly summarized as follows: Insert the rivet into the pre-drilled hole, the rivet gun starts to pull the mandrel, the tail of the cap expands and clamps the material on the back, then the mandrel breaks at a specific notch, and finally a reliable and non-loose connection is formed. This entire process only takes a few seconds, which is an important reason why Pop Rivet is popular in mass production.

Step-by-Step: How to Install Pop Rivets?

The process for installing Pop Rivets is straightforward: first select the correct rivet size and material, ensuring the grip range matches the plate thickness. Then drill a hole with a diameter matching the rivet, swiftly deburring the edges to ensure a flush fit. Next, insert the rivet into the hole and use a rivet gun to sever the mandrel, completing the expansion and securing the rivet. Finally, inspect the back for a full, symmetrical formation. Should incorrect installation or insufficient expansion occur, simply drill out the centre to reinstall.

| Step | Action | Why It Matters |

|---|---|---|

| 1 | Select the correct rivet | Determines final strength and compatibility with sheet thickness |

| 2 | Drill the hole and control diameter | Incorrect hole size can cause looseness or prevent proper expansion |

| 3 | Deburr the hole | Prevents poor seating and stress concentration |

| 4 | Insert the rivet | Ensures uniform expansion and proper alignment |

| 5 | Use a rivet gun to pull and break the mandrel | Creates the final clamping force needed for a secure joint |

| 6 | Inspect the formed rivet | Confirms strength, sealing, and vibration resistance |

| 7 | Drill out and reinstall if incorrect | Blind rivets are non-removable and must be drilled out for rework |

① Choose the correct rivet

- Select rivets made of aluminum, steel, stainless steel, etc. based on the material of the base metal.

- Choose the correct Grip Range (clamping range) according to the total plate thickness.

- The length of the rivet should be: plate thickness + 1.5D – 2D (length required for expansion).

The material and length of the rivet determine whether it can fully expand, whether it will loosen or break. Mismatch of the grip range can lead to insufficient clamping or inability to be pulled apart.

② Mark the position and drill holes

- Use a drill bit that matches the diameter of the rivet, for example, a 3.3mm drill bit for a 3.2mm rivet.

- The tolerance of the hole diameter must be controlled within +0.1mm.

③ Remove burrs

Use a chamfering tool or file to gently remove the burrs around the hole. Burrs can prevent the cap from fitting tightly, causing the rivet head to lift and the connection to become loose.

④ Insert the rivet into the hole

The cap of the rivet should be tightly against the outer side of the workpiece. Keep the rivet perpendicular to the surface of the plate. An inclined installation will cause uneven expansion, affecting the shear strength and also resulting in an asymmetrical appearance.

⑤ Use a riveting gun to break the mandrel.

Use a manual, pneumatic or electric rivet gun. Pull the rivet gun until you hear a “pop” and the mandrel breaks.

The mandrel pulls the tail of the cap body to expand, forming a real locking force. The fracture must be correct; otherwise, the rivet will not expand enough and will become loose.

⑥ Check the riveting forming effect

Check three key points:

- Whether the rivet head is fully flush with the surface.

- Whether the backside expansion is uniform and mushroom-shaped.

- Whether the mandrel breaks at the correct position.

These details determine the final shear resistance, tensile strength and waterproof performance.

⑦ How to Fix Incorrect Installation

Use a drill bit slightly larger than the mandrel to drill into the center of the rivet. Remove the cap and the expansion body.

Clean the hole → reinstall a new rivet.

Blind rivets are non-removable. Once they are not formed properly, they can only be repaired by “drilling out”. This is the safest method and the one least likely to damage the parent material.

Pop Rivet Installation Chart

| Rivet Diameter | Drill Bit Size | Hole Size (mm) | Typical Grip Range | Recommended Rivet Length |

|---|---|---|---|---|

| 3.2 mm (1/8″) | #30 drill bit | 3.3 mm | 0.5 – 3.0 mm | 6–8 mm |

| 4.0 mm (5/32″) | #20 drill bit | 4.1 mm | 1.0 – 4.0 mm | 8–10 mm |

| 4.8 mm (3/16″) | #11 drill bit | 4.9–5.0 mm | 1.5 – 6.0 mm | 10–12 mm |

| 6.4 mm (1/4″) | #6 drill bit | 6.5–6.6 mm | 2.0 – 8.0 mm | 12–16 mm |

During the installation process of Pop Rivets, many problems do not stem from the rivets themselves, but rather from installation mistakes. The following five types of errors are the most common and are most likely to cause structural failure, loosening or leakage. Each point is accompanied by an engineering consequence explanation to enhance credibility.

- Oversized Hole Size

When the diameter of the coupler rivet is too large, after the rivet expands, it cannot fully grip the base material. It is recommended to control the hole diameter within the range of the rivet diameter + 0.1 mm. - Wrong Grip Range

The Grip Range determines whether the rivets can expand properly. Incorrect selection will result in insufficient clamping force, loose structure or poor formation. - No Deburring

If the burrs are not removed after drilling, the head of the rivet cannot fit smoothly. This will cause stress concentration, causing the rivet to gradually loosen during vibration. In waterproof applications, it will even lead to the risk of water seepage. - Incompatibility of materials leads to galvanic corrosion

If the potential difference between the rivet material and the base material is too large, electrochemical corrosion will occur. For example: aluminum plate + stainless steel core shaft, it will corrode more rapidly outdoors. Solution: Use insulating gaskets or change the material combination. - Not Enough Blind-Side Clearance

Blind rivets require space on the backside for expansion. When the space is insufficient, the rivets cannot fully expand. Poor formation can lead to decreased shear strength, deformation of the rivet body, and even complete failure. Before installation, it is necessary to check the Blind-Side Space.

FAQ About Installing Pop Rivets

Q1. How to instaall pop rivets without a gun?

Screws and washers may be used for manual riveting in the absence of a rivet gun, though the resulting finish is inferior and this method is not recommended for structural components. This technique employs screws to pull the mandrel, but the tension is inconsistent and may result in insufficient rivet expansion.

Q2. Do pop rivets need pre-drilled holes?

Yes, the vast majority of Pop Rivets require pre-drilling, with the hole diameter matching that of the rivet itself; otherwise, they may become loose or fail to expand properly. Only a few “self-drilling rivets” are exceptions, but their applications are limited.

Q3. Why won’t my pop rivet break off?

This is typically due to the rivet not being fully drawn, an incompatible grip range, an excessively large hole, or insufficient draw force from the rivet gun. Switching to a more powerful rivet gun or checking the dimensions should resolve the issue.

Q4. Why is my rivet loose after installation?

The most common causes are excessive hole diameter, failure to deburr, excessively thin material, or incorrect selection of the grip range. Looseness indicates insufficient expansion; it is recommended to re-drill and reinstall.

Q5. Do pop rivets work on plastic?

Yes, but large flange rivets or types specifically designed for soft materials must be used to prevent tearing. Plastic is prone to deformation, so tensile forces must be reduced and the load-bearing area increased.

Get Free Rivet Samples & Engineering Support from Rivmate

If you are choosing the right Pop Rivets for your project, or if you are unsure about the correct hole size, grip range, and material compatibility, the Rivmate engineering team can provide you with free support. We offer:

- Free Nail Samples: Suitable for batch trial assembly, process verification and structural testing.

- Free Aperture / Grip Range Check: Tell us the plate thickness and material, and we will adjust the hole diameter, rivet diameter and clamping range for you.

- Engineering Support: Our engineers can offer professional advice based on the load, environment and materials.

- OEM Packaging and Long-Term Supply Support: Suitable for brand owners, distributors and equipment manufacturers to reduce procurement costs.

Contact us immediately to obtain free samples or have an engineer review your project parameters.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met