Table of Contents

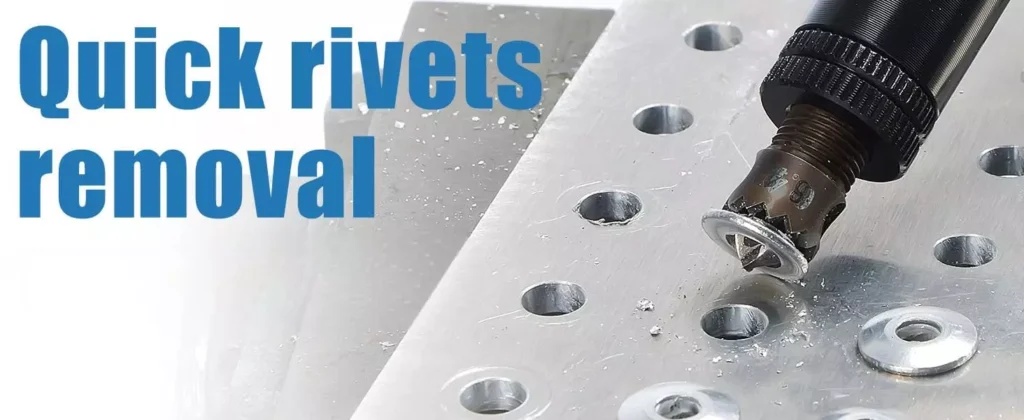

For sheet metal projects, rivets are a cost-effective and very efficient way to make connections. But how to remove rivets when you encounter them? This blog will describe the topic around how to remove rivets.

By reading this blog, you will learn about 5 common ways to remove rivets and how to choose the most appropriate way to remove rivets.

Table of Contents

Why Remove Rivets?

The reasons for removing Blind Rivets are usually related to repairs, replacements, design changes or quality issues.

- Parts Repair or Replacement: When the equipment or structural parts to be riveted need to be disassembled, replaced or overhauled, the original blind rivets must be removed first.

- Design or process adjustment: In the assembly trial production stage, if the design program is modified or components need to be repositioned, the original blind rivets must be removed.

- Riveting quality is not up to standard: If the blind rivets are found to be riveting failure (such as not clamped, broken core incomplete, cap edge warping, etc.), need to be re-removed and reassembled to ensure structural safety.

- Replacement of connection: Some assembly processes may replace the blind rivets with reversible or stronger connections such as screws, welding, gluing, etc. The original blind rivets need to be removed first.

- Material or Appearance Protection: In the event that a rivet is incorrectly installed or misaligned, it needs to be removed to avoid damaging the surface of the component or causing a concentration of material fatigue points.

- Safety Considerations and Structural Inspections: If individual rivets are found to be loose, corroded, rusted or broken during regular inspections of the structure, they must be removed and replaced to ensure overall connection reliability.

Do You Have Any Questions?

Let Us Solve Your Problem

Old Methods of Removing Rivets

Although the connection provided by blind rivets is a permanent one, there are a variety of ways to remove it. Each method produces a different result, and if you are removing a large number of rivets, then the method of removing the rivets will be different.

I. Rivets Removal using an electric drill (the most common and effective method)

Using a power drill to remove rivets is a very common method. If you only need to remove a small number of rivets with failed installations, a power drill to remove rivets would be a very convenient and quick solution. You can manually drill the rivets out. However, the accuracy of removing rivets using a power drill is far less than using a specialized rivet removal tool. And this method is likely to deform the hole or damage the workpiece. In addition, if the rivets to be removed are dome head blind rivets, it may be difficult to center the drill bit on the rivet head to cleanly drill out the rivet.

It is important to note that the drill bit needs to match the size of the rivet mandrel.

Steps for removing rivets using an electric drill

- Choose the right drill bit: the diameter of the drill bit should be slightly smaller than the diameter of the rivet cap (usually use the same or slightly smaller than the rivet mandrel diameter of the drill bit, such as 3mm, 4mm, etc.).

- Fixed workpiece: to avoid the workpiece shaking or shifting during drilling.

- Align the rivet center vertically: drill from the cap face and punch through the rivet break point until the cap edge comes off.

- Remove rivet body residue: gently tap out the remaining rivet shell with a punch or screwdriver.

pros of removing rivets with drill bits

- Efficient and suitable for most metal and structural rivets

- Controlled process for precision removal

II. Use of angle grinders or cutters (for structural rivets)

In addition to using a drill to remove the rivets, you can use an angle grinder to cut the rivets out. This method of removing rivets is quicker, but it is not suitable for all situations.

Using an angle grinder to remove rivets will definitely damage the rivet construction and the surface of the workpiece. This is the quickest way only if you are dismantling a workpiece or item and disposing or recycling it and do not intend to reuse it.

Steps for removing rivets using angle grinders

- Select a metal cutting blade and cut it off along the edge of the cap.

- Then use a punch to tap out the rivet body.

points to note when removing rivets with angle grinders

- Suitable for riveting high strength steel structures

- Risk of flying chips, goggles and gloves required

- May damage workpiece surfaces, not recommended for use in visible areas

III. Use a chisel + hammer

For the very rare removal of failed rivets, you can just use a hammer and chisel. The removal method is the same as using a sander, which is to cut the rivet head, but it can be quite time consuming and labor intensive.

Steps for removing rivets using a chisel and hammer

- Use a punch to center the rivet and tap with a hammer to push the rivet out.

- Again use a punch or small screwdriver to push the rivet body out of the hole.

pros of removing blind rivets with chisels and hammers

- No need for power tools, suitable for field or no power environment

- Suitable for aluminum rivets, plastic parts and other soft materials

Do You Have Any Questions?

Let Us Solve Your Problem

New Methods of Removing Rivets

Use of specialized pop rivet removal tools

The Pop rivet removal tool is specifically designed to remove rivets that have already been installed. This removal method does not damage the drilled holes and you can still install rivets in the original holes.

The Pop rivet removal tool has a device similar to the open hole drilling/directional drilling jig on its internal structure to help stabilize drilling and prevent slippage. The specialized rivet removal tool is ideal for batch or high precision removal and is frequently used in the aerospace and automotive repair industries.

Special material handling methods (e.g. plastics, composites)

- Plastic panels: Heat rivets with a hot knife or fusion tip soldering pencil, soften and pull out.

- Fragile surfaces: slowly cut the cap edge with a hand knife/carver to avoid vibration damage to the material

How to Choose the Right Methods of Remove Rivets?

1. Rivet material

- Aluminum rivets: Aluminum blind rivets are soft and easy to deform. They can be removed manually and by electric drill.

- Steel/stainless steel rivets: steel is harder and generally has higher tensile strength. It is recommended to use an electric drill or angle grinder to remove.

- Structural rivets: structural rivets have a locking structure inside and have higher shear strength. It is recommended to use an angle grinder or special rivet removal tool.

- Plastic Rivet: Plastic is softer and has a lower melting point. They can be softened with a hot knife/welding pencil.

2. Connector Material

- Metal parts: can withstand drilling and hammering.

- Plastic/composite materials: need to prevent high temperature, cracks from striking, should choose hot knife or manual method.

- Fragile or decorative surfaces: Specialized drilling fixtures are recommended to prevent damage to the surface from off-set drilling.

3. Conditions of available tools

- With power drill: preferred drilling for removal

- Without power tools: use punch/hammer or hand cut removal

- With Angle Grinder: Quickly remove structural rivets.

- Need high precision: choose specialized Rivet Removal Tool

Practical Choice Logic Table

| Condition | Recommended Method |

| Removing aluminum rivet + electric drill available | Use drill method (fast and safe) |

| Removing stainless rivet + no electricity | Use punch + hammer or angle grinder |

| Large/structural rivets | Angle grinder or structural rivet remover |

| High-sensitivity or aesthetic surface | Jig-guided drill with stopper bit |

| Plastic/composite-mounted rivet | Hot knife or manual cut |

Buy High Quality Blind Rivets from Rivmate

By reading this article, I am sure you already know how to remove rivets. if you want to avoid removing rivets ahead of time, then you need to use high quality blind rivets to minimize the occurrence of rivet failure. You need to buy high quality blind rivets from a reliable rivet manufacturer.

You can obtain free samples of rivets for testing before purchasing them.

Get Rivets Quote

You may also find these topics interesting

Buy Open Type Blind Rivets

Buy Structural Blind Rivets