Table of Contents

Rivets are the most suitable fasteners for joining sheet metal. Do you know how to rivet sheet metal? Do you know how to riveting sheet metal with pop rivets?

By reading this article, you will know exactly how to choose the best rivets for your sheet metal project. This includes how to choose sheet metal rivets and how to install them properly.

Table of Contents

Basic Knowledge of Riveting

What is Riveting?

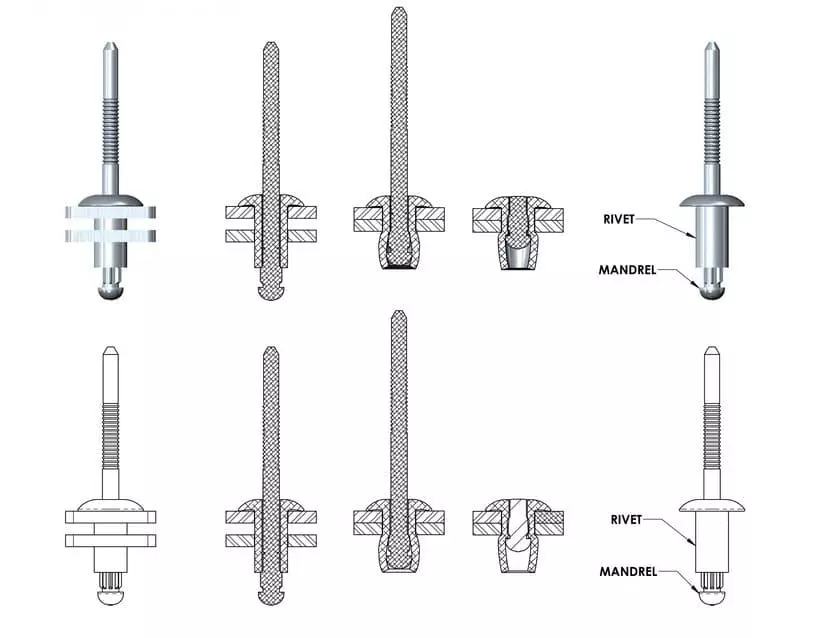

Riveting is a method of permanent mechanical joining in which two or more materials, usually sheet metal, are fastened together by means of a rivet. In riveting, the rivet is inserted into the material through a drilled hole and mechanically deformed to form a strong connection that cannot be easily removed.

The technique of riveting is used in a wide variety of industries, including aerospace, construction, automotive, electronic equipment, bridge manufacturing, and more. If your project requires strong, durable, vibration-resistant structural connections, riveting is a great solution.

Riveting vs Welding vs Screw: When to Choose Riveting?

The connection created by riveting is a permanent one. If you have a product that also requires high strength, vibration resistance, no heat effects, or a special material bond, then you should choose riveting. Here are some typical application scenarios:

- Joining dissimilar materials: riveting is suitable for joining dissimilar materials (e.g. aluminium + steel, stainless steel + plastic), whereas welding is usually only suitable for metals of the same or similar material. Examples include aircraft skins (aluminium alloy + titanium alloy), car bodies (aluminium + steel).

- Materials that cannot withstand high temperatures: riveting is a cold process that does not change the physical properties of the material. Examples include aerospace, electronic equipment housings, lightweight aluminium structures, avoiding the heat affected zone (HAZ) created by welding.

- Need to resist vibration and not loosen: riveted joints are more vibration resistant than screws and will not loosen due to long term vibration like screwed joints. Examples include aircraft, rail trains, bridges, and motorbike parts. These structures are subject to constant vibration and should be selected for riveting.

- Need long durability, can not be frequently maintained: riveted joints are suitable for structures that can not be frequently overhauled. For example, building bridges, ships, railways, etc. Welding may crack due to fatigue and screws may loosen due to vibration.

- Suitable for large-scale automated production: riveting is more suitable for assembly line production than welding.

How to Choose Rivets for Sheet Metal

In sheet metal connections, the choice of the right rivet is critical. This choice will have a direct impact on the strength, durability, corrosion resistance and assembly efficiency of the sheet metal connection. Below is a detailed guide to rivet selection, including rivet type, material, finish and application industry.

1. Types of Rivets Suitable for Sheet Metals

| Rivet Type | Features | Application Scenarios |

| Blind Rivet (Pop Rivet) | Single-side operation, easy installation, suitable for mass production | Sheet metal, electronics, appliances, automotive interiors |

| Countersunk Blind Rivet | Flat surface after riveting, ideal for applications requiring a smooth finish | Automotive, aerospace, furniture |

| Sealed Blind Rivet | Waterproof, airtight, suitable for moisture-resistant applications | Shipbuilding, HVAC, outdoor equipment |

| Self-Piercing Rivet (SPR) | No pre-drilling required, directly pierces metal, high strength | Automotive manufacturing, aluminum sheet metal |

| Exploding Rivet | Prevents deformation of soft metals or composites | Thin aluminum sheets, electronic enclosures |

| Multi-Grip Rivet | Suitable for varying thicknesses, reduces inventory | Sheet metal fabrication, assembly workshops |

Standard blind rivets actually fulfil the strength requirements of the vast majority of sheet metal.

2. Choose the Right Rivet Material

| Rivet Material | Features | Compatible Sheet Metal | Application Scenarios |

| Aluminum | Lightweight, corrosion-resistant, cost-effective | Aluminum, stainless steel | Automotive, home appliances, electronics |

| Stainless Steel | High strength, corrosion-resistant, heat-resistant | Aluminum, stainless steel, carbon steel | Construction, railways, outdoor equipment |

| Carbon Steel | High strength but prone to rust | Steel, stainless steel | Bridges, steel structures |

| Copper/Brass | Aesthetic appeal, good conductivity | Copper, brass | Electronics, electrical components |

Recommended Combinations:

- Aluminium rivets + Aluminium sheet metal (light weight & corrosion resistant)

- Stainless Steel Rivet + Stainless Steel Sheet Metal (High Strength & Corrosion Resistance)

- Aluminium rivets + steel sheet metal (to avoid galvanic corrosion).

3. How do I Select the Correct Rivet Size?

The correct rivet size (diameter & length) will ensure a strong connection without being too tight or too loose.

Rivet Length = Total Material Thickness + 1.5 x Rivet Diameter

- Thin metal (≤1mm): choose 3.0mm or 3.2mm diameter rivets.

- Medium thickness (1~2.5mm): choose 4.0mm or 4.8mm diameter

- Thick metal (≥2.5mm): select 5.0mm or larger

Example (if the total thickness of the two layers of sheet metal = 2mm, select the appropriate rivet):

- Recommended diameter: 3.2mm or 4.0mm

- Recommended length: 2mm + (1.5 × 3.2mm) ≈ 6.8mm, use 7mm rivets.

4. Surface Treatment of Rivets for Sheet Metal

| Surface Treatment | Features | Suitable Environment |

| Anodizing | Enhances corrosion resistance, suitable for aluminum rivets | Outdoor, humid environments |

| Zinc Plating | Cost-effective rust protection | General industrial use |

| Stainless Steel Natural Finish | Built-in corrosion resistance | Marine, chemical environments |

| Powder Coating | Aesthetic appearance, additional protection | Furniture, decorations, signage |

5. Recommended rivets for different industries

| Industry | Recommended Rivet Type | Reason |

| Automotive Manufacturing | Self-Piercing Rivets (SPR), Aluminum Blind Rivets | High strength, lightweight, suitable for aluminum sheet metal |

| Construction & Facades | Stainless Steel Sealed Rivets | Waterproof, corrosion-resistant, suitable for outdoor structures |

| Home Appliances & Electronics | Aluminum or Stainless Steel Blind Rivets | Lightweight, aesthetic, easy assembly |

| Aerospace | Solid Rivets, Countersunk Rivets | High strength, fatigue resistance |

| Shipbuilding & Marine | Stainless Steel Sealed Rivets | Saltwater-resistant, waterproof sealing |

Do You Have Any Questions?

Let Us Solve Your Problem

Preparation of Riveting Sheet Metal

Before riveting thin metal, proper preparation ensures a strong, accurate connection and long service life.

- Correct rivet type, size, and material selected

- Metal sheets securely clamped and aligned

- Drilled holes are clean and deburred

- Personal safety equipment is in place

- Work area is organized and free of obstructions

How to Rivet Sheet Metal?

Guide to Step-by-Step Rivet in Sheet Metal

- Drill: Begin by drilling the hole where you will place your Rivet.

- Insert: Insert the Rivet into the hole.

- Rivet: Use a riveting gun with bucking bars to set the Rivet into place.

- Inspection: Check that the rivets are flush and secure.

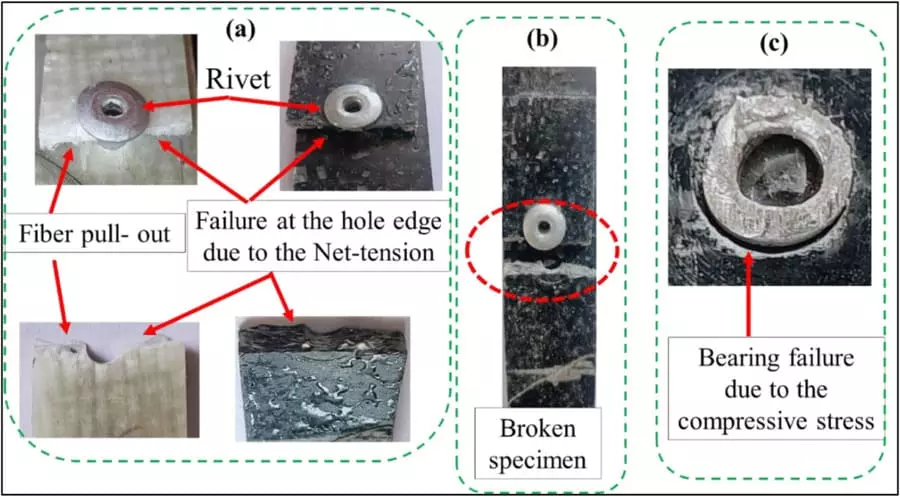

Inspection after Riveting Sheet Metal

After the installation is complete, we need to do a brief check on the riveting results. Mainly observe the following three parts:

- Rivet head: whether allowance metal surface, no gap.

- Rivet tail: whether it is evenly spread and closely fit.

- Surface flatness: whether the surface of the rivet and the plate is flat.

How to Fix Incorrect Rivet Joints?

Different riveting problems require different repair solutions, the following are common riveting errors and their corresponding repair methods:

Loose or Rotatable Rivets

How the hole in the sheet metal is too large and the rivet is not long enough, then it may result in insufficient riveting force. You will need to replace the rivets with larger diameter or longer rivets to ensure that the rivets can be fully deployed and form a tight joint.

Rivet not fully expanded

Usually pop rivets are not fully expanded because the force applied by the installation tool is not sufficient. Or the rivets themselves are of poor quality. It is necessary to replace the rivets with high quality rivets and adjust the force applied by the tool to ensure that the rivet tails are spread evenly.

Rivet head not adhering to the metal surface

There are two things that can cause this problem: 1. Sheel metal is too thin. 2.The riveting force is too high causing deformation.

In this case you need to use short rivets or add shims on the back.

Broken or excessively deformed rivets

There are three reasons for this problem: 1. too much mounting force applied 2. poor quality rivets 3. wrong material.

You need to use stronger rivets. Also adjust the tension of the rivet gun.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Pop Rivets for Sheet Metal Project

A blind rivet is a type of rivet designed for sheet metal. Rivmate is one of the top 3 sheet metal rivets manufacturers in China, you can get professional sheet metal rivets solutions.

Obtain samples for testing immediately!