Large Flange Pop Rivets

Large Flange Pop Rivets enhance connection stability by increasing the rivet head diameter to provide greater contact area, ensuring more uniform load distribution. They are the ideal choice when requiring stronger joint strength and better material protection.

The large flange design effectively protects material surfaces by reducing localized stress concentration, minimizing the risk of cracking or deformation in thin sheets or brittle materials during riveting. Simultaneously, the expanded bearing area enhances pull-out resistance, ensuring a more secure and reliable connection.

Furthermore, large-flange blind rivets are particularly suited for brittle or soft materials such as thin sheet metals, plastics, and composites. Aesthetically, their prominent heads can serve both structural and visual purposes in certain applications.

Types of Large Flange Head Pop Rivets

Large Flange Pop Rivets feature a head design not achievable with all pop rivet types. The larger flange demands higher forming precision and material control, making its manufacturing process relatively complex. This places greater demands on mold design, material ductility, and production stability. Consequently, few manufacturers can reliably produce large flange pop rivets.

From an application perspective, large flange pop rivets are ideal for joining soft or easily deformed materials. The larger flange diameter significantly increases the load-bearing surface area, reducing localized stress concentration and effectively lowering the risk of material tearing or crushing. This structural advantage is particularly evident in applications involving thin sheet metal, plastics, and composite materials.

Large Flange Open Type Blind Rivets

Large Flange Sealed Type Blind Rivets

Large Flange Peel Type Blind Rivets

Large Flange Multi Grip Blind Rivets

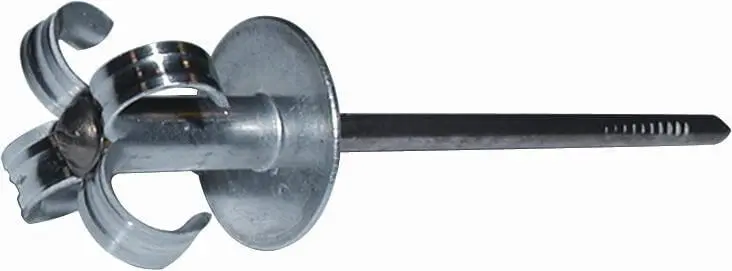

Large Flange Tri Fold Rivets

Large Flange Head Q Rivets

Rivmate – Custom Large Flange Head Pop Rivets for You

Rivmate is one of China’s leading manufacturers and suppliers of pop rivets, possessing mature production expertise and stable delivery capabilities in large flange pop rivets. Whether you require any type of large flange pop rivets or large flange head blind rivets, and regardless of whether you choose aluminum, steel, or stainless steel materials, Rivmate can provide a matching product solution.

Leveraging our proprietary production system and standardized quality management processes, Rivmate maintains dimensional and performance consistency throughout bulk supply. This is particularly crucial for large flange rivets, which demand higher precision in head forming and material control. Through rigorous process control, we ensure reliable load-bearing capacity and effective material protection during actual assembly.

Rivmate not only delivers high-quality blind rivets but also provides tailored riveting solutions for diverse industry assembly needs. Whether for thin-sheet structures, soft materials, or applications demanding aesthetic and safety compliance, our engineering team offers expert support.

Choosing Rivmate means choosing consistent product quality, expert technical support, and long-term reliable service partnerships. In the realm of riveted components, trusting Rivmate will help your projects achieve greater efficiency and more controllable assembly quality.

Large Flange Rivet Sizes

Similar to other head types of pop rivets, Large Flange Pop Rivets also offer multiple diameter specifications to accommodate assembly scenarios with varying thicknesses and strength requirements. Selecting the appropriate rivet diameter is one of the key factors in ensuring connection strength and material protection.

Common specifications for large flange pop rivets include:

3/32″ (2.4 mm), 7/64″ (3.0 mm), 1/8″ (3.2 mm), 5/32″ (4.0 mm), 3/16″ (4.8 mm), 6/32″ (5.0 mm), 15/64″ (6.0 mm), and 1/4″ (6.4 mm).

These sizes cover a wide range of applications, from light-duty sheet metal connections to medium-load structural fastening.

When selecting, consider material type, total clamping thickness, and working load simultaneously. By matching the appropriate diameter with the clamping range, large flange pop rivets ensure reliable connections while offering enhanced material protection and assembly consistency.

Large Flange Rivet Materials

Large Flange Head Blind Rivets can be manufactured from various metallic materials to suit applications with differing strength, environmental, and cost requirements.

Aluminum

Aluminum large flange blind rivets are lightweight with good corrosion resistance, making them suitable for light-duty applications. They are commonly used to join aluminum sheets, thin metal plates, and plastic components. Aluminum rivets are a frequent choice in weight-sensitive scenarios or where rust prevention is critical.

Carbon Steel

Carbon steel blind rivets offer higher tensile and shear strength, making them suitable for medium to heavy-duty structural connections. Often paired with surface treatments like zinc plating to enhance corrosion resistance, they are widely used in industrial equipment, steel structures, and mechanical assemblies.

Stainless Steel

Stainless steel large-flange blind rivets combine high strength with excellent corrosion resistance. They are suitable for humid, corrosive, or hygienically demanding environments, such as outdoor equipment, food processing machinery, and chemical-related applications. Although more costly, they offer extended service life in harsh conditions.

Applications of Large Flange Pop Rivets

If your project is to use pop rivets to join plastic materials, then LARGE FLANGE POP RIVES is perfect for you.

Plastics are prone to cracking or pulling through under the high concentrated forces of standard rivets. large flange pop rivets prevent material damage by evenly distributing the stress through the larger flange head, ensuring that the material is not torn or damaged during riveting.

Large Flange Pop Rivets for Sheet Metal

Large flange pop rivets are ideal for joining thin metal sheets, thin aluminum sheets, steel sheets, etc.

Thin materials are susceptible to deformation and even rupture due to concentrated stress when subjected to standard rivets. Large flange pop rivets increase the area of force, so that the stress is more evenly distributed over the thin material, preventing deformation of the material during the riveting process.

Large Flange Pop Rivets for Wood Project

Large flange pop rivets are used in applications where the rivet is prone to pull-through. this type of material is weaker and more susceptible to being pulled through during the riveting process. The larger flange head size provides better load distribution and additional surface support to prevent the rivet from pulling out of the material under tension.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Advantages of Large Flange Blind Rivets

Many unique projects will exclusively use LARGE FLANGE HEAD BLIND RIVETS to complete the connection process. This is because large flange head blind rivets offer several unique advantages, especially in applications that require enhanced stress distribution and increased joint strength.

- Larger force area

- Enhanced tensile and shear strength

- Prevents deformation or cracking of thin materials

- Higher vibration resistance

- Suitable for a wide range of materials and applications, including brittle materials such as plastics.

What is the Difference Between Regular Rivets and Large Flange Rivets?

| Comparison Criteria | Regular Rivets | Large Flange Pop Rivets |

| Head Size | Smaller head, limited coverage area | Larger head, wider coverage area |

| Pressure Distribution | Concentrated pressure on a small area, may damage softer materials | Better pressure distribution, reducing material damage |

| Suitable Materials | Suitable for harder, thicker materials | Suitable for soft, fragile, or thin materials like plastic, thin metal, composites |

| Load Bearing Capacity | Lower load-bearing capacity | Higher load-bearing capacity, ideal for applications needing extra support |

| Vibration Resistance | More prone to loosening in high-vibration environments | Larger head provides better vibration resistance |

| Aesthetic Appearance | Smaller head, suitable for hidden or low-profile applications | Larger head, suitable for applications requiring visible or decorative finishes |

| Thickness Range | Best for thicker materials | Suitable for thin or multi-layer materials |

| Application Scenarios | Commonly used in general fastening, such as sheet metal and machinery | Used where more support and protection are needed, such as plastic, thin sheets, and outdoor structures |

| Shear and Tensile Strength | Lower shear and tensile strength | Higher shear and tensile strength |

| Preventing Material Deformation | Can cause deformation in softer or thinner materials | Larger head prevents material deformation, especially in soft and thin materials |

| Cost | Lower cost, suitable for high-volume production | Slightly more expensive, ideal for applications with special requirements |

Are Large Flange Pop Rivets Suitable for Use in High Vibration Environments?

Yes, large flange blind rivets are ideal for use in high vibration environments. The larger head of the large flange disperses pressure and increases stability, preventing loosening under vibration or dynamic loads. And LARGE FLANGE BLACK RIVETS offer the following advantages.

- Better Grip: Larger surface area provides better grip and reduces the possibility of loosening due to vibration.

- Enhanced Stability: In high vibration environments, such as automotive or industrial machinery applications, the larger contact area of large flange rivets reduces material movement and ensures that the rivet is securely fastened.

How Big is the Flange Diameter of Large Flange Pop Rivets?

Large flange pop rivets have a larger flange diameter than standard rivets. The purpose of this design is to provide a larger force area to prevent deformation or breakage of the material.

In general, the flange diameter of large flange blind rivets is usually twice or more the diameter of the rivet stem. The following is a typical range of specifications:

- 1/8” (3.2mm) rivets: flange diameter is approximately 6.35mm – 7.0mm.

- 3/16” (4.8mm) rivets: flange diameter is approximately 9.5mm – 10mm.

- 1/4” (6.4mm) rivets: flange diameter is approximately 12.7mm – 13.5mm.

Does a Larger Flange Head Result in a Better Riveted Joint?

The larger the flange head of a blind rivet, the better the riveting will not necessarily be. This depends largely on the specific application requirements and material properties.

The larger flange head of a blind rivet provides a larger force area. This provides higher shear and tensile resistance while effectively preventing the material from being pulled through.

However, in some space-constrained or weight-sensitive projects, a larger flange head may not be suitable. The larger the flange head, the more space the rivet will take up and the more weight will be added. In addition to this, rivets with larger flange heads typically cost slightly more than standard rivets because more material is required to manufacture them.

How Do Large Flange Pop Rivets Disperse Stress?

Large flange blind rivets are mainly used to disperse stresses more effectively by increasing the contact area of the flange head.

The larger contact area of large flange blind rivets can effectively solve the problem of several kinds of stress and enhance the support of the material.

Wholesale Large Flange Pop Rivets from China

If you’re seeking a reliable Pop Rivet manufacturer, Rivmate is a trusted choice. As a specialized pop rivet production facility, we consistently supply a wide range of specifications and materials for Large Flange Blind Rivets, meeting diverse assembly and industrial application needs.

Leveraging mature production techniques and standardized quality control systems, Rivmate maintains consistent dimensions and performance in bulk shipments, helping reduce assembly risks and enhance production efficiency. Whether for thin sheet metal, plastics, or other soft materials, we provide tailored riveting solutions.

Sample testing is crucial for engineering selection. Contact us today to obtain samples, verify assembly results, and prepare for future bulk procurement.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!