Table of Contents

Lockbolt vs huck bolt is an issue that engineers should know more about. Do you often hear the names lockbolt and huck bolt. Do you get confused? This blog will give you a comprehensive explanation of lockbolt vs huck bolt. so that you can have an in-depth understanding of them.

Table of Contents

What is a Lockbolt?

Lockbolt was invented to solve the following problems:

- loss of preload under use loads

- fixation and relaxation effects in threads

- self-relaxation effects under vibration loads

- Relative motion in the thread bearing region

Lockbolt is a two-piece fastener consisting of a nail tip and a metal collar. This type of lockbolt provides extremely strong clamping force and can secure heavy equipment.

During installation, a special lockbolt tool is used to clamp the end of the lockbolt’s tip, and then the tool is activated so that the collar is pressed into the groove of the tip, and the installation is complete.

What is a Huck Bolt?

Actually, in the engineer’s opinion, lockbolt and huck bolt are the same type of fastener. This is because huck bolt refers to all bolt type fasteners produced by huck, while lockbolt refers to a special type of bolt produced by huck.

Over time, however, both names now refer to the lockbolt rivet.

Types of Lockbolt/Huckbolts

Lockbolt/Huckbolts is just an umbrella name for one type of fastener. there are still many types of lockbolt/huckbolt under Lockbolt/Huckbolt. Let’s take a brief look at them together.

Lockbolt with Breakpoints

Lockbolt with breakpoints is the most commonly used hucklock. this type of lockbolt/huckbolt will disconnect from the breakpoints when the installation is complete.

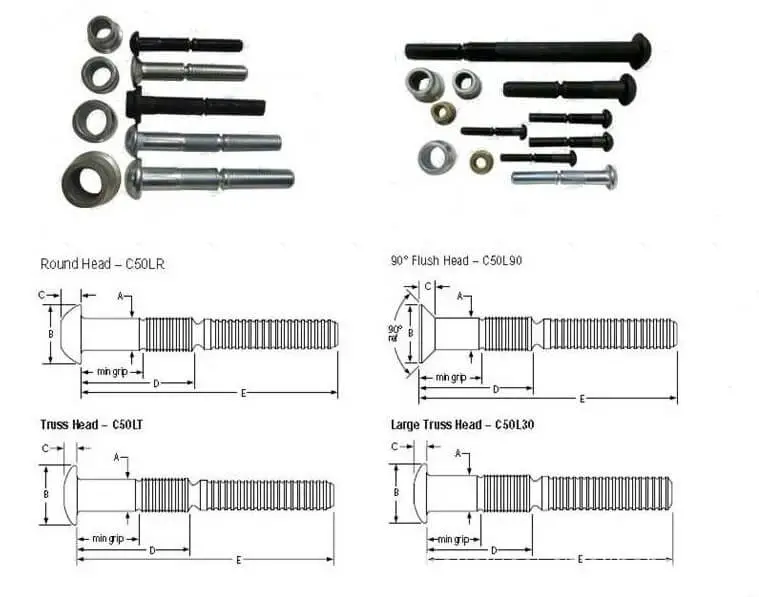

Common types are Huck C6L Lockbolt, Magna-Grip, C50L Lockbolt.Lockbolt has many lengths to choose from.Lockbolt also has many types of head styles, such as round head, countersunk head.

Lockbolt without Breakpoints

The lockbolt without breakpoint is designed with a solid tip that will not leave any metal residue. This type of lockbolt/huckbolt will have less installer fatigue as there will be no shock from removing the pin end during installation. In addition, because lockbolt without breakpoints does not remove the pin end to expose the metal, future corrosion is avoided.

If you want to know a little bit more about the types of Lockbolts. You can read this article of ours which details the differences and application scenarios of the different types of lockbolts.

Advantages of Lockbolt/HuckBolts

Though in the field of fasteners, threaded fasteners are still very much in use. But it has a major problem, threaded fasteners such as nuts and bolts can loosen over time, especially in high stress applications or where constant vibration is an issue.Lockbolt/Huck Bolts were invented to solve this problem.Lockbolt/Huck Bolts offer benefits that traditional threaded fasteners do not.

- They are corrosion resistant and can be installed with light tools. And they are available in steel, stainless steel and aluminum.

- Designed for heavy-duty applications, they exceed ASTM A-325 standards for shear and tensile strength.

- Has a wide grip range that allows different connection lengths to be addressed at once.

- Some special lockbolt can be installed with constant pressure to handle softer materials without crushing them.

Why Use Lockbolt/Huckbolt Instead of Welding?

In the past, welding was the optimal solution for joining joints subject to high vibration. However, in most of today’s industrial applications, welding has been replaced by other joining methods. Welding is now considered impractical and unsafe. Below I have listed some of the main reasons for using lockbolt instead of welding.

1.Sufficient Security

The welding process generates a lot of sparks, which can easily cause a fire. Moreover, welding a joint may result in a large amount of spent welding rod, which may become a safety hazard in the production plant. The welding process will produce some harmful gases, which may cause the operator to suffer from lung cancer, asthma and other diseases. So, after the invention of lockbolt, welding was gradually replaced by Huckbolt which does not produce any of the above mentioned problems.

2.Fast Installation

Welding (especially complex welding) takes time, which can affect production time, and HuckBolts provides fast, reliable installation. With welding, your material must be spotless before joining, but with HuckBolts, this is not necessary. They are very easy to install.

3.They are not Affected By the Heat Affected Zone

With Lockbolt, you don’t have to worry about the effects of high temperatures due to the Welding may damage the surface of the material being joined or even melt the surface material of the material. But Lockbolt does not generate any heat during installation and does not damage the material in any way. The structural integrity of the workpiece is guaranteed.

Frequently Asked Questions About Lockbolt vs Huckbolt

To save you time, we have listed some frequently asked questions about lockbolt/huckbolt for you.

1.Can Lockbolt/Huck Bolts Replace Nuts and Bolts?

The Lockbolt was designed to replace nuts and bolts when it was first engineered. To address their shortcomings, the Lockbolt/Huckbolt is ideally suited for joining applications that require high clamping forces and need to be vibration resistant. For example, railroad track connections, connections to critical parts of automobiles, and connections to components such as airplane wings.

2.Can Lockbolt's Vibration Resistance Avoid Vibration Altogether?

Sure. The original Lockbolt was designed to solve this problem. And it has resisted rail and train car insurance track vibration in practice. Conventional nut and bolt combinations need to be re-tightened periodically, a maintenance process that can be a major headache. It can even be dangerous.

Lockbolt/Huckbolt is designed so that it does not vibrate. There is no relative movement between its collar and the tipped pegs. And installation is very easy. It requires basically no human maintenance.

3.Are Lockbolt/Huckbolt Permanent?

Lockbolt is a permanent, high-strength connector compared to traditional nut-and-bolt fasteners. Once an engineer has completed the installation, it can be difficult to remove lockbolt. So in some applications where lockbolt rivet is installed, there is no need for human supervision. It will not be lost.

Buy Lockbolt or Huckbolt from China Manufacturer

Are you looking for reliable lockbolt supplier for your project?Rivmate is a good choice for you.Rivmate is the top pop rivet manfuacturer in China.We can provide you with various types of rivets and high strength lockbolt,bom rivet.

Whether you want to buy the appropriate lockbot accessories for your industrial equipment or a large number of lockbolts for your project, you can get higher quality lockbolts from Rivamte at a lower price.

Contact us now!