Table of Contents

How to choose metal rivets for steel project? Do you know what type of metal rivets are appropriate for different Steel materials? This article will tell you the answer.

Table of Contents

Why Do You Need Metal Rivets for Steel?

In practice, there are many ways to connect STEEL materials. So why do we use metal rivets?

There are many reasons, but the main reason is to ensure the strength, durability and reliability of the connection of STEEL materials. Here are a few of the main reasons for using metal rivets to join steel:

- Metal rivets can provide enough tensile and shear strength

- Good durability. Ability to maintain performance under harsh environmental conditions.

- Matching coefficient of thermal expansion. Can reduce the risk of stress concentration and deformation at the joint due to inconsistent thermal expansion.

- Metal rivets have sufficient toughness and impact resistance.

- It can provide high reliability and ensure the integrity and safety of the STEEL structure.

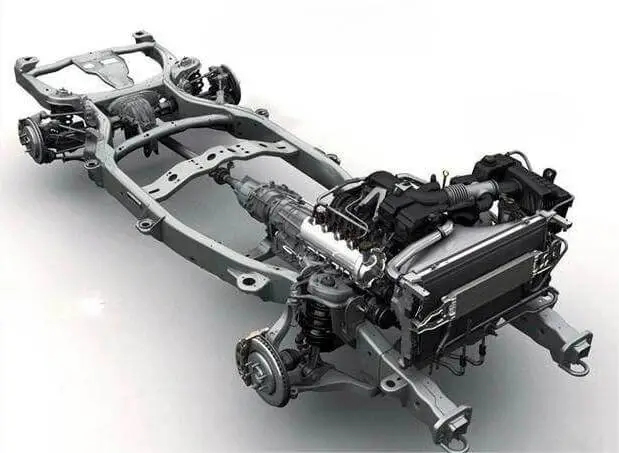

Metal rivets, especially steel rivets. When it is used for the connection of steel materials, it ensures the stability and reliability of steel structures in various application scenarios.

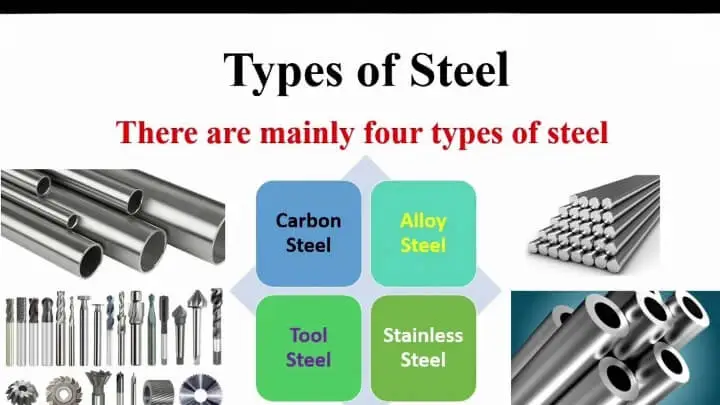

Types of Steel

Steel is an alloy material composed primarily of iron and carbon, with other elements often added to enhance its properties. There are very many types of steel, which can be categorized according to their composition, production process, heat treatment and applications. The following are the main classifications of steel:

Classification by Chemical Composition

Based on the chemical composition of STEEL, it can be categorized into the following three types:

- Carbon Steel

- Alloy Steel

- Stainless Steel

Based on the carbon content, Carbon Steel can be categorized into Low Carbon Steel (carbon content <0.25%), Medium Carbon Steel (0.25% < carbon content < 0.6%), and High Carbon Steel (carbon content > 0.6%). Carbon Steels with different contents are suitable for different applications and their strengths are listed in descending order: Low Carbon Steel, Medium Carbon Steel, High Carbon Steel. The higher the carbon content, the greater the strength and hardness.

The distinction between alloy steel and stainless steel is also a criterion. Alloy steel is differentiated according to the content of alloying elements: low alloy steel(Alloying element content <5%), medium alloy steel(5%<Alloying element content<10%), high alloy steel(Alloying element content>10%). Stainless steel can be divided into 304, 316, 430, 410, 420, 2205 stainless steel.

Classification by Production Process

Rolled Steel

- Hot Rolled Steel: Produced by rolling at high temperatures, e.g. hot rolled plates and sections. Good workability and weldability.

- Cold Rolled Steel: Produced by rolling at room temperature, such as cold rolled sheet and cold rolled strip. High surface quality and precision.

Forged Steel

- Free Forged Steel: Produced by the free forging process and used to manufacture large and complex shaped parts.

- Die forging steel: produced through the die forging process, used to manufacture parts for mass production.

Cast Steel

Produced by the casting process for the manufacture of complex shaped parts.

Classification by Application

According to the different scenarios and uses of steel, it can be divided into the following categories:

- Structural Steel

- Tool Steel

- Spring Steel

- Bearing Steel

- Alloy Structural Steel

- Heat-Resistant Steel

Classification By Special Properties

- Corrosion-Resistant Steel

- Wear-Resistant Steel

- Low-Temperature Resistant Steel

- Electrical Steel

What is The Best Rivet for Thin Metal?

Which type of rivet is best for joining thin sheets of metal? I think you are interested in this question.

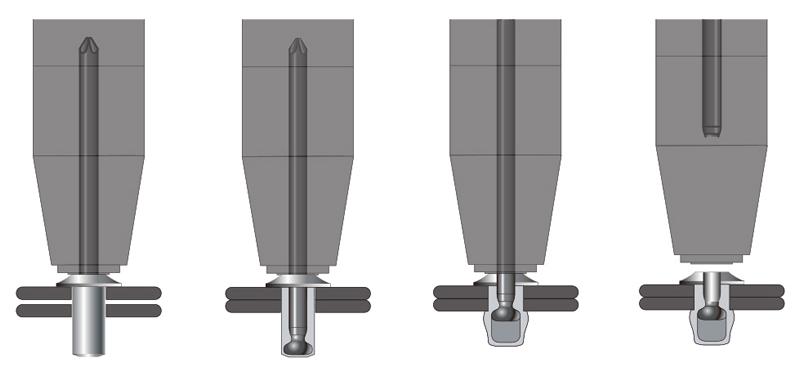

Rivets are designed to join thin sheet metal. So there are many types of rivets that can join thin sheet metal.For exampleFor example, open endFor example, open end rivetsOpen end rivets, for example.For example, open end rivets, peel For example, open end rivets, peel rivets, closed end rivets, and blind rivets.

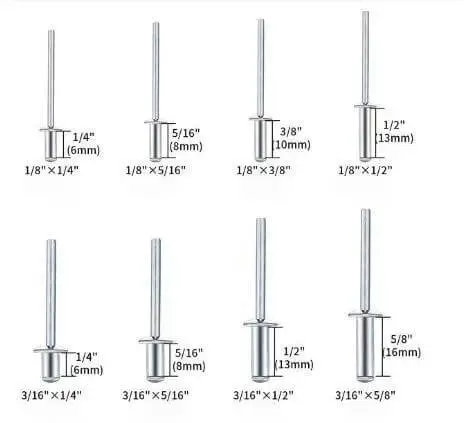

So how do I choose a rivet? It’s simple, you just need to think about it from two aspects. They are 1. material match 2. rivet size

You need to select a rivet material that is compatible with the metal material being joined. For example, for aluminum plates, to prevent galvanic corrosion, you need to use aluminum or coated steel rivets. Apart from this, you need to make sure that the size and clamping range of the rivet can fit your thin sheet material.

How to Install Metal Rivets?

Why Use Rivets Instead of Welding?

Why do engineers use rivets instead of welding? Because rivets have many unique advantages that welding does not.

1.Material and Thickness Adaptability

- Joining dissimilar materials: rivets can join different types of materials, such as metals to plastics, composites, etc., whereas welding is usually limited to joining similar metals.

- Thin Plate Materials: Rivets are particularly suitable for joining thin plate materials, as welding thin plates tends to cause deformation, burn-through or structural weakness, whereas rivets do not create these problems.

2.Resistance to Vibration and Dynamic Loads

- Resistance to vibration and shock: Rivets perform well in high vibration and dynamic load environments and are less prone to loosening or failure, whereas welded joints may suffer fatigue cracking under these conditions.

- Long-term stability: riveted joints provide excellent fatigue resistance, especially for applications that require long-term exposure to vibration and shock.

3.Ease of Installation and Operating Conditions

- One-sided operation: Some rivets (e.g., blind rivets) can be operated from one side, which is useful when space is limited or when it is not possible to operate from both sides.

- Simplicity and safety: Riveting does not require high temperatures, which makes it easier and safer than welding, especially in field installations and repairs.

4.Construction and Connection Quality

- Uniform Quality: Riveted joints provide consistent quality that is not greatly affected by the skill level of the operator, whereas weld quality is highly dependent on the skill level of the welder and the control of the welding process.

- Thermal deformation control: The riveting process does not generate excessive heat, avoiding thermal deformation of the material and structural stress concentrations, which is particularly important in precision manufacturing and thin material connections.

5. Repair and Maintenance

- Easy to remove and replace: rivets can be removed by drilling out or cutting, making them easy to repair and replace, whereas welding usually requires cutting and re-welding, a complex and time-consuming process.

- On-site repair: Riveting is suitable for on-site repair and is especially convenient when quick replacement or repair is required.

6.Environment and Safety

- No fumes or harmful gases: riveting does not involve high temperature operation, no fumes or harmful gases are generated, reducing the impact on the environment and operator health.

- Safe operation: The riveting process does not involve electric arcs or flames, making it safer to operate, especially in explosion-proof areas or environments with flammable substances.

Frequently Asked Questions About Metal Rivets for Steel

As we all know, time is of the essence. I have listed a few frequently asked questions to save you time.

Can I Use Aluminum Rivets on Steel?

It is possible to use aluminum rivets on steel materials. But it needs to be well guarded. This is because there are several potential problems and hazards associated with using aluminum rivets on steel materials:

- Galvanic Corrosion: Galvanic corrosion can occur between steel and aluminum, which can weaken the strength of the rivet and the reliability of the connection, ultimately leading to connection failure.

- Strength Differences: Aluminum rivets are typically lower in strength and hardness than steel materials. The connection may not be able to withstand the design loads, resulting in deformation of the rivet, breakage or loosening of the connection.

- Different coefficients of thermal expansion: Steel and aluminum have different coefficients of thermal expansion. In temperature changing environments, the two materials expand and contract at different rates. Concentrations of stress in the joint may result in loosening of the rivet or fatigue damage to the steel material.

- Durability and longevity: Aluminum rivets typically have lower durability and longevity than steel rivets, increasing the frequency and cost of maintenance and replacement.

Of course, you can solve these problems by using insulating shims or coatings between the rivet and the steel to prevent direct contact.

Can You Use Copper Rivets on Steel?

Using copper rivets on STEEL has similar problems as aluminum rivets. There is a risk of galvanic corrosion between copper and steel. And there is a difference in their strength and hardness, with copper being much less hard. So there is no way for copper to provide the strength that steel needs.

Copper rivets are generally used for conductive applications or for decorative purposes. So it is not suitable to use copper rivets to provide the high strength connection that steel needs.

Why Buy Metal Rivets from China Manufacturer?

When a company owner opens a new project that requires materials, they are often the first to consider importing from China. This is because importing metal rivets from China can be very helpful for your business.

Save Your Money

labor and manufacturing costs are lower in China, so you can get the metal rivets you need at a lower price.

Complete Industry Chain

China has a complete industry chain, you can solve all your sourcing problems at once.

Strong Production Capacity

Whether for large or small orders, Chinese manufacturers can flexibly cope with them.

Order Metal Rivet. Rivmate Can HelP You Project

Rivmate is a leader and innovator in metal riveting. Our decades of experience and dedication have allowed us to develop durable, efficient and extremely reliable blind rivet and metal rivets.

If your project requires the use of high quality metal rivets, then your business should consider our value-added services such as PPAP documentation and customized rivet solutions.

Work with Rivmate to get an edge on the competition. Contact us today!