Bulk Monel Rivets for Sale

Monel Rivets are manufactured from high-performance Monel nickel-based alloy, primarily composed of approximately 63–70% nickel and 20–29% copper, with trace amounts of iron, manganese, and other elements. This composition achieves an exceptional balance between strength and corrosion resistance.

Benefiting from its high nickel content, Monel rivets demonstrate outstanding corrosion resistance in seawater, salt spray, acidic media, and high-humidity environments while maintaining high tensile and shear strengths. Compared to standard stainless steel, Monel offers extended service life and more stable performance under certain extreme operating conditions.

Consequently, Monel Rivets are frequently employed for critical connections in demanding environments, such as marine and offshore equipment, chemical processing plants, and energy and aerospace applications.

Monel Rivets for Sale

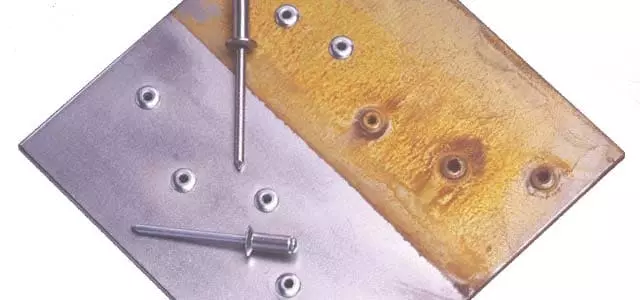

We offer various types of Monel Rivets, including Solid Rivets and Blind Rivets, to accommodate different installation conditions and structural requirements.

For special operating conditions or project requirements, we also support customized services, such as non-standard dimensions, specific structural designs, or unique application needs. Please contact us, and our engineering team will assist in developing a suitable Monel riveting solution based on your operating environment and performance requirements.

Monel Solid Rivets

Monel Blind Rivets

Dome Head Monel Rivets

Countersunk Monel Pop Rivets

Custom High Quality Monel Rivets from Monel Rivets Suppliers

Compared to rivets made from other materials, Monel Rivets offer several irreplaceable performance advantages. Among their most prominent features is exceptional corrosion resistance in seawater and salt spray environments. The high nickel content ensures Monel maintains stable performance even during prolonged immersion or in highly saline conditions, making it widely used in ships, offshore platforms, and marine equipment.

In terms of mechanical properties, Monel rivets combine high tensile strength with superior shear strength, meeting the demands of high-load and critical structural connections. This makes them suitable not only for corrosion-resistant applications but also for scenarios requiring exceptional structural integrity.

Precisely because Monel rivets are typically deployed in demanding conditions involving high corrosion and high strength, their material costs and manufacturing complexity are significantly higher than those of conventional aluminum or steel rivets. The production process demands stricter control over raw materials and greater process stability. Therefore, selecting a Monel rivet supplier with proven experience and robust quality control capabilities is critical, as this directly impacts the long-term reliability and service life of the project.

Monel Rivets Applications

Marine Environment

Monel is extremely resistant to salt water corrosion and galvanic corrosion. As a result Monel Rivets excel in marine environments and are suitable for long term exposure to salt spray and moisture.

- Shipbuilding: for fastening components such as hulls, decks, cabins and portholes.

- Offshore drilling rigs: for fastening structural components and pipe connections in extreme salt water environments.

- Diving equipment: Fastening of metal parts for submarines, deep-sea submersibles and other underwater equipment.

Chemical and Petrochemical Industry

Monel Rivets are resistant to acids and alkalis, especially sulfuric, hydrochloric and hydrofluoric acids. Suitable for use where there is contact with corrosive chemicals.

- Chemical equipment: for fasteners in reactors, tanks and piping systems.

- Oil & Gas Equipment: Used in refineries and gas pipelines to prevent corrosion and high temperature damage.

Highly Corrosive Building Environments

Monel material has two distinctive features: 1. long service life 2. virtually maintenance free. Therefore monel rivets are ideally suited for use in offshore or highly corrosive environments.

- Offshore construction: fastening of docks, marine bridges and coastal protection.

- Buildings in high humidity areas: e.g. steel fixings for coastal high-rise buildings.

Military and Defense

Monel rivets can be used in enviously harsh environments. For example, military equipment and installations.

- Warships and submarines: for the immobilization of critical components, capable of resisting extreme marine conditions.

- Ammunition storage equipment: providing corrosion-resistant and high-strength fixing solutions.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Monel Blind Rivets Sizes

We offer a wide selection of monel blind rivets sizes for different applications.

Available sizes:

- 3.2×10mm – 1/8″×3/8″

- 4×11mm – 5/32″×7/16″

- 4.8×13mm – 3/16″×1/2″

- 4.8×19mm – 3/16″×3/4″

- 6×13mm – 1/4″×1/2″

- 6×17mm – 1/4″×11/16″

Advantages of Monel Rivets

High Strength:Monel alloy exhibits superior strength compared to pure nickel and many pure metals, making it suitable for withstanding significant tensile and shear loads.

Excellent Corrosion Resistance:Demonstrates stable performance in diverse corrosive environments, ensuring extended service life.

Outstanding Seawater Resistance:Demonstrates exceptional resistance to salt spray and seawater, making it widely used in marine and offshore applications.

High Acid Resistance:Withstands diverse acidic environments, suitable for chemical processing and energy-related equipment.

High Melting Point:Maintains structural integrity under high-temperature conditions without softening or failure.

Exceptional Toughness:Ensures reliable connections even under impact or vibration.

Stable Properties at Extreme Temperatures (Stable Performance in Extreme Temperatures):Maintains mechanical properties and dimensional stability in both high-temperature and low-temperature environments.

Why Use Monel Rivets?

Although Monel is a relatively high-cost metal material, Monel Rivets remain widely used in demanding engineering projects. This is because their chemical composition and microstructure provide a combination of properties unmatched by most metals, making them irreplaceable under severe operating conditions.

- Exceptional Corrosion Resistance: Crafted from a nickel-copper alloy, Monel rivets exhibit outstanding resistance to salt spray, seawater, and high-humidity environments, resisting rust formation. They also withstand diverse acidic and alkaline media, including hydrochloric acid, sulfuric acid, and hydrofluoric acid, making them ideal for chemical processing and offshore marine applications.

- High Strength and Toughness: Monel rivets exhibit high tensile and shear strength, capable of withstanding substantial mechanical loads. Their exceptional toughness ensures stable connections even under impact and vibration.

- Superior High-Low Temperature Performance: They resist softening or failure at elevated temperatures while maintaining good toughness at low temperatures without brittle fracture. This characteristic makes them suitable for extreme temperature differentials.

- Long-Term Stability and Low Maintenance Costs: With excellent fatigue resistance and durability, Monel rivets exhibit low failure risk during extended service life. This significantly reduces maintenance and replacement frequency, offering cost advantages from a full lifecycle perspective.

When applications demand corrosion resistance, high strength, and extreme environmental stability simultaneously, Monel Rivets—despite higher initial costs—remain a worthwhile choice for high-performance fastening solutions, offering superior safety, reliability, and long-term cost efficiency.

Monel Alloy Grades and Material Comparison

When selecting Monel rivets, the alloy grade directly determines their corrosion resistance, strength level, and suitability for specific operating conditions. The following overview of common Monel grades and their comparison with 316 stainless steel facilitates engineering procurement and technical selection.

Common Monel Alloy Grades

- Monel 400: A precipitation-hardening alloy primarily composed of nickel and copper, offering excellent resistance to seawater and salt spray with stable mechanical properties. Widely used in conventional high-corrosion environments for marine vessels, offshore structures, and chemical processing equipment.

- Monel K-500: Developed from Monel 400 by adding elements like aluminum and titanium, achieving higher strength through precipitation hardening. Suitable for critical structural connections requiring both high strength and corrosion resistance.

Alloy Composition and Performance Differences

Monel alloys’ high nickel content provides outstanding corrosion resistance, while copper enhances stability in seawater and salt spray environments. K-500 offers higher tensile and shear strength than 400, but comes with increased cost and processing complexity, typically used in high-safety-level applications.

Monel vs. 316 Stainless Steel Comparison

Compared to 316 stainless steel, Monel demonstrates greater stability in prolonged seawater immersion, high-salinity conditions, and certain acidic media, with lower risks of pitting and crevice corrosion. 316 stainless steel offers advantages in cost and versatility, while Monel is better suited for applications in extreme corrosion environments and those demanding high reliability.

For applications primarily in marine, offshore, or chemical environments where failure risk costs are high, Monel alloy rivets offer greater long-term value. In relatively mild environments, 316 stainless steel serves as an economical alternative.

Corrosion Resistance and Environmental Performance of Monel Rivets

In highly corrosive and complex operating conditions, the environmental adaptability of Monel Rivets is one of the core reasons for their widespread adoption. Compared to conventional fastener materials, Monel exhibits superior long-term stability in a variety of harsh media.

Performance in Salt Spray, Seawater, and Acid/Alkali Environments

Monel alloys, based on high nickel content, inherently resist seawater and salt spray. They remain resistant to pitting and crevice corrosion in prolonged marine exposure. Monel maintains stable performance in acidic and alkaline media, making it suitable for chemical processing, offshore engineering, and offshore equipment applications.

Corrosion Resistance Comparison with Stainless Steel and Carbon Steel

Compared to carbon steel rivets, Monel exhibits minimal susceptibility to rust and requires no surface coatings for long-term service. Compared to 316 stainless steel rivets, Monel demonstrates superior corrosion resistance in high chloride ion environments, with lower corrosion risk under prolonged immersion conditions. It is suitable for more demanding service environments.

Long-Term Service Stability

Monel Rivets exhibit minimal performance degradation under prolonged loading and harsh environmental conditions. The combination of fatigue resistance and corrosion resistance significantly reduces maintenance frequency and replacement costs, enhancing the overall long-term reliability of structures.

For projects in marine, high-salinity, or chemically corrosive environments demanding high safety and longevity standards, Monel Rivets provide a more assured fastening solution.

Reilable Monel Rivet Suppliers

If you’re seeking a reliable Monel Rivet supplier, Rivmate is your trusted choice. We specialize in high-performance riveting solutions crafted from Monel alloys to meet engineering demands in highly corrosive, high-strength, and demanding environments.

Product Range

- Monel Solid Rivets: Ideal for double-sided access and applications demanding maximum strength.

- Monel Blind Rivets: Suitable for single-sided installation scenarios, balancing strength and construction efficiency.

- Dome Head Monel Blind Rivets: Versatile with uniform load distribution.

- Countersunk Head Monel Blind Rivets: Flush-mounted for applications demanding aesthetic appeal and surface flatness.

Specification Capabilities

- Common Diameters: 1/16″ – 5/16″

- Standard Lengths: 3/16″ – 2-1/4″

- Customization Support: Diameter, length, and head type can be customized per project requirements

Our proven manufacturing and inspection processes ensure batch consistency and long-term reliability. Products are widely used in offshore, marine, chemical, energy, and highly corrosive environments.

For projects with special operating conditions or non-standard requirements, contact our engineering team for selection guidance and technical support.

Rivmate—Your Premier Monel Rivet Supplier. Contact us today for a quote.

Contact Us for Monel Rivet Samples

Rivmate is a top blind rivet manufacturer in China. You can get many kinds of monel rivets samples from Rivmate.Rivmate can provide professional monel rivets solutions for you. Whether you need solid rivets or blind rivets, we can supply them all. Get your rivet samples for testing today.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!