Wholesale Monobolt Rivets from China Factory

Monobolt Rivets (structural one-way rivets) are high-strength structural blind rivets specifically designed for applications demanding exceptional joint strength and reliability. Through their unique locking mechanism, Monobolt rivets achieve stable, controlled mechanical locking upon installation, delivering joint performance comparable to solid rivets or high-strength bolts even under single-side installation conditions.

Monobolt Rivets are widely used in heavy equipment, construction machinery, commercial vehicles, rail transit, steel structural components, and industrial equipment manufacturing. They are suitable for replacing certain high-strength bolts or welded connections to enhance installation efficiency and reduce overall assembly costs.

Types of Monobolt Rivets

We offer a wide selection of monobolt rivets for a variety of applications. Including sizes, materials and head styles.

Carbon Steel Monobolt Rivets

Stainless Steel Monobolt Rivets

Aluminum Monobolt Rivets

Dome Head Monobolt Rivets

100° Csk Head Monobolt Rivet

Wholesale High Quality Monobolt Rivets

Monobolt Rivets are typically used in scenarios demanding exceptional structural strength, installation consistency, and long-term reliability. Inconsistent rivet quality can easily lead to connection failure, loosening, or rework risks, thereby compromising the safety and service life of the entire project. Therefore, selecting a reliable Monobolt Rivets manufacturer with a stable quality control system is crucial.

Rivmate stands as one of China’s leading manufacturers of structural hollow rivets, specializing in the R&D and mass production of high-strength Monobolt Rivets. Our products rigorously align with international mainstream brands in structural design, raw material selection, and manufacturing processes. They meet the technical requirements of established application systems like Avdel and Huck, and are certified under IATF 16949 and ISO 9001 quality management systems. This ensures high consistency in strength, dimensions, and assembly performance across every batch.

For standard specifications, Rivmate reliably supplies Monobolt Rivets in commonly used diameters such as 4.8 mm, 6.4 mm, and 9.8 mm. These are widely applicable in heavy equipment, construction machinery, commercial vehicles, steel structures, and industrial assembly fields. Additionally, for specialized operating conditions or customized project requirements, we offer tailored solutions for materials, dimensions, clamping ranges, and performance parameters to precisely match your specific application scenarios.

Advantages of Monobolt Rivets

- Structural breakstem rivets: Designed for high-load and high-reliability connection applications.

- Visible external locking method: Features a visible external locking structure for post-installation quality verification.

- 100% mandrel retention: The mandrel is fully locked and retained within the rivet body, eliminating the risk of loosening or detachment.

- Extremely wide riveting range: Capable of accommodating diverse material thickness combinations.

- High shear and tensile strength: Delivers exceptional shear and tensile strength to meet structural-grade connection requirements.

- High clamping force: Generates significant clamping force during installation, ensuring long-term connection stability.

- Excellent hole filling properties: The rivet body fully expands during installation, achieving superior hole filling.

- Blind hole, single side mounting capability: Supports single-side mounting in blind hole structures, suitable for applications where the back side is inaccessible.

- Large gap closing capability: Possesses excellent gap compensation ability, effectively bridging assembly tolerances.

Monobolt Rivet Sizes

We offer a variety of specifications for Monobolt Rivets (High-Strength Structural Hollow Rivets) to meet connection requirements for structures ranging from medium to heavy loads.

Currently available standard specifications include:

- 4.8 mm (3/16″): Suitable for structural connections requiring medium strength, balancing strength with installation efficiency.

- 6.4 mm (1/4″): Commonly used in industrial assembly scenarios requiring higher load-bearing capacity, offering both high shear strength and stable clamping force.

- 9.8 mm / 10 mm (3/8″): Suitable for heavy-duty applications or those requiring high safety factors, such as heavy equipment, construction machinery, and steel structural components.

Applications of Monobolt Rivets

Automobile Manufacturing

Widely used for connecting body structural components, brackets, and functional modules, ensuring assembly consistency and structural safety while withstanding vibration and dynamic loads.

Cabinets and Enclosures

Suitable for structural connections in industrial cabinets, electrical enclosures, and control panels, delivering high clamping force with stable external appearance and internal structural integrity.

Commercial Vehicles

Commonly used in structural assembly for trucks, trailers, and specialty vehicles, meeting reliability requirements under high loads and long-term operational conditions.

Household Appliances

Employed in critical structural areas of products like washing machines, refrigerators, and air conditioners, balancing strength, installation efficiency, and mass production consistency.

Heating and Ventilation Systems

Suitable for frames, ductwork, and support structures in HVAC equipment, ensuring secure, non-loosening connections under prolonged operation and vibration.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Why Use 316/A4 Stainless Steel for Stainless Steel Monobolt Rivets?

In high-strength structural connections, material selection determines the reliability and service life of Monobolt Rivets. The widespread use of 316 / A4 stainless steel in premium structural Monobolt Rivets is no coincidence. It offers distinct advantages in corrosion resistance, long-term stability, and total lifecycle cost.

Superior Corrosion Resistance in Harsh Environments

The core strength of 316 / A4 stainless steel stems from its chemical composition. This material typically contains 2–3% molybdenum (Mo). Molybdenum significantly enhances resistance to chloride ions. In salt spray, high humidity, or coastal environments, corrosion ranks among the primary failure causes for Monobolt Rivets.

Compared to 304/A2 stainless steel, 316 demonstrates superior stability against pitting and crevice corrosion. Based on ASTM B117 salt spray test experience, 316 stainless steel exhibits significantly longer failure times in chlorine-containing environments. This is why offshore equipment, outdoor structures, and HVAC systems increasingly favor 316 Stainless Steel Monobolt Rivets.

Enhanced Performance for Structural Riveting Applications

Monobolt Rivets are structural pop rivets. They endure prolonged tensile loads, shear forces, and continuous vibration. Material stability is paramount. 316/A4 stainless steel demonstrates greater reliability against stress corrosion cracking.

Performance degradation is minimal in high-humidity or temperature-fluctuating environments. This makes them ideal for commercial vehicles, heavy equipment, and industrial structural components. For structural Monobolt Rivets, material reliability often outweighs short-term strength.

Higher Compatibility with High-Strength Monobolt Rivets Design

The core of Monobolt Rivets lies in their locking mechanism. This includes the mandrel locking zone and high clamping force design. Materials must match structural strength requirements. 316/A4 stainless steel resists plastic failure under high clamping forces, ensuring greater stability in the mandrel locking zone. The locking mechanism maintains integrity under prolonged loading. Inadequate material grades compromise the full advantages of high-strength Monobolt Rivets.

Lower Life-Cycle Cost for Long-Term Projects

316/A4 stainless steel Monobolt Rivets carry a higher initial cost. However, their total life-cycle cost is lower. Over extended service periods, they reduce replacement frequency due to corrosion. They also minimize maintenance and rework risks.

For export projects, equipment with extended warranties, or critical structural connections, 316 Stainless Steel Monobolt Rivets are the preferred engineering choice.

Compliance with International Standards and Market Expectations

316 stainless steel corresponds to A4 Stainless Steel (ISO 3506) in international standards. This material grade is widely recognized in Europe and high-end industrial markets. Monobolt Rivets using A4 material more readily pass customer audits and better align with technical specifications from OEMs, equipment manufacturers, and EPC contractors. In many projects, the material grade itself serves as an entry barrier.

Surface Treatment of Monobolt Rivets

Surface treatment directly impacts the corrosion resistance, appearance consistency, and long-term reliability of Monobolt Rivets across diverse environments. We offer multiple proven surface treatment solutions tailored to various industries and applications, with customization available to meet specific project requirements.

Zinc Plated

Monobolt Rivets enhance corrosion resistance by forming a protective zinc layer on the steel substrate. This zinc coating acts as a sacrificial anode, preferentially corroding in hostile environments to shield the rivet body. Meeting common industry standards, conventional zinc plating typically passes 48–96 hours of salt spray testing (ASTM B117) in neutral environments. Suitable for cabinets, commercial vehicles, and general industrial structures, it represents a cost-effective yet reliable choice.

Natural Finish

Monobolt Rivets with this surface treatment undergo no additional coating after forming, retaining the material’s raw state. This method eliminates coating peeling risks and offers high dimensional stability, though corrosion resistance depends entirely on the base material. Suitable for dry environments, indoor applications, or internal structural locations, it’s commonly used for stainless steel Monobolt Rivets or scenarios with minimal aesthetic requirements.

Natural Polish

Monobolt Rivets undergo mechanical polishing on top of the natural finish, resulting in a smoother, more uniform surface. The reduced surface roughness helps minimize dirt adhesion and corrosion initiation points while enhancing visual quality and assembly consistency. This treatment is typically used for equipment and structural connections requiring higher standards for appearance, cleanliness, or perceived quality.

Custom Monobolt Rivets

Rivmate offers professional Monobolt Rivet design and customization services. We support multiple head types, size ranges, and surface treatment options to match varying structural strength and assembly requirements.

For surface treatments, we provide standard solutions including zinc plating, natural finish, or natural polished finishes. We also support tailored adjustments based on usage environments—such as durability optimization for outdoor or corrosive conditions.

For mass production projects, customized Monobolt Rivets enhance assembly consistency. This reduces rework and improves overall assembly efficiency.

If your project involves unique structural or performance requirements, we recommend consulting our engineers early. Preliminary technical evaluations help identify suitable Monobolt Rivet solutions faster and ensure smooth project progression.

To meet your unique assembly requirements, please contact our engineers.

Monobolt Rivets Tool

We offer a wide range of equipment and tools for the installation of structural blind rivets. For information about monobolt rivet tool, please read the following pages.

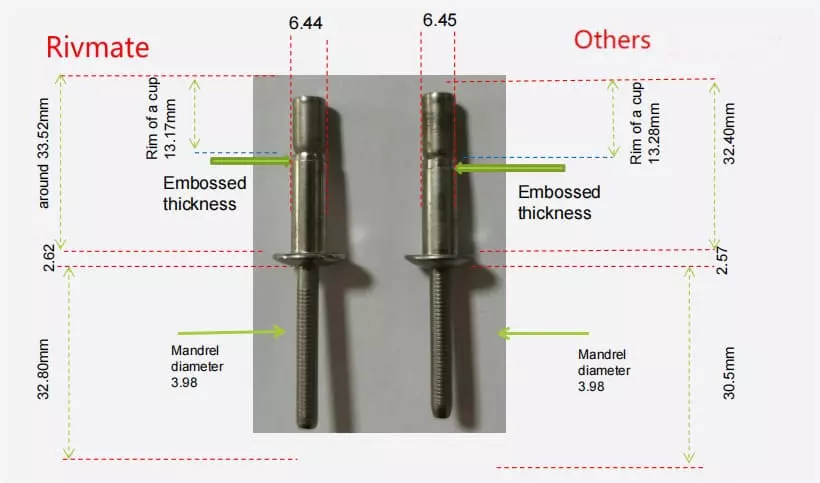

Rivmate Monobolt Rivet vs Other Monobolt Rivet

Compared to other brands, Rivmate monobolt

Rivmate monobolt rivets are similar in size and construction, with a slightly different mandrel rolling process, but both meet the riveting requirements.

Rivmate monobolt rivets and other brands of rivets can meet the requirements of the mandrel locking effect after riveting.

Mechanical properties: When the hole diameter of 6.8mm and riveted thickness of 8.0mm, Rivmate rivets pull-out parameters of the minimum value of 9000N, the average value of the measured about 9800N.

Order High Quality Monobolt Rivets from Rivmate

If you you are planning to purchase mono-lock rivets. please contact us!

Rivmate is one of the top 3 blind rivet manufacturer and supplier in China.You can get far beyond standard quality and excellent customer service.

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!