Home » Peel Pop Rivets

Peel Pop Rivets

Peel pop rivets are ideal for joining thin materials such as aluminium, steel, ABS plastic and fibreglass. Particularly fragile and soft materials such as carbon braze, fibreglass, PVC, ABS and other components.

Order peel pop rivets in bulk from peel rivet supplier to suit your project.Rivmate can supply large quantities of peel type blind rivets.

Complete Your Project with Rivmate's Peel Pop Rivets

As one of the top peel rivet suppliers in China, we are able to provide high quality products to customers all over the world. And we can provide customised peel rivets services and solutions. Scroll your mouse to view our products and contact us. Choose your ideal type of peel rivets!

Dome Head Peel Type Blind Rivets

The head of the dome head peel type blind rivets is rounded. It can provide a smooth and beautiful finish. Ideal for applications requiring an aesthetic appearance and high load dispersion capability.

Large Flange Head Peel Type Pop Rivets

Large flange head peel rivets combine a large flange head design with an effective peel cut tail mechanism. Particularly suitable for applications requiring additional support and high load spreading capacity.

Colored Exploding Peel Rivets

If your project has a requirement for the exterior colour of peel rivets, you can ask us. We will fulfil your needs!

Custom Peel Rivets

Does your project have special requirements for the specification of peel pop rivets? Don’t worry, Rivmate can solve all your purchasing problems at once!

Peel Rivets Gun

Rivmate offers more than just various types of peel rivets, it also offers relative connection tools. You don’t need to go anywhere else to buy them! Save time and cost!

Peel Rivets Supplier

If you are looking for peel rivets supplier, Rivmate is the right choice for you. We can take all kinds of orders.

Rivmate:Leading Peel Rivets Supplier Near You

Rivmate is a peel rivets supplier in China.Our professional engineers will provide you one-stop sourcing solution. Besides peel rivets, Rivmate also provides many types of blind rivets, high strength structural rivets, rivet nuts and tools for joining.

Peel pop rivets are used in a wide range of applications and are particularly suitable for joining brittle or soft materials. You can also ask us to apply a special surface treatment to the peel rivets according to your project requirements.

As a leading supplier and manufacturer of peel rivets in China. You can quickly get the products you need from our large stock. We can fully meet all your needs.

Custom Peel Rivets to Complete Your Business

Custom Head Style of Peel Rivets

Rivmate can provide you with both Dome heads and large heads. Of course, We can customise a special head shape for your project.

Custom Materials of Peel Rivets

- Carbon Steel

- Aluminum

Custom Body Length of Peel Rivets

- Minimum: 10.0mm

- Maximun: 26.0mm

If the peel rivets you need to buy have special length requirements, you can contact us for customisation.

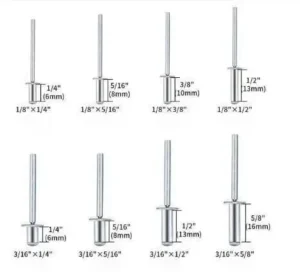

Custom Diameter of Peel Rivets

- 3.2mm(1/8″)

- 4.0mm(5/32″)

- 4.8mm(3/16″)

- 6.4mm(1/4″)

Custom Color of Peel Rivets

If your project has special requirements for the colour of the peel rivets, you can offer us a custom-made one. You can get a satisfactory solution from Rivmate.If you do not specifically request a colour when placing your order, we will deliver it in the original colour of the peel rivets.

Custom Grip Range of Peel Rivets

- Minimun:1.0mm

- Maximum:28.0mm

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Buy Peel Pop Rivets

Why Choose to Buy Peel Rivets From Rivmate?

If you want to buy the best peel pop rivets, then you have come to the right place!

Rivmate is the top pop rivet manufacturer in China.We are committed to providing our customers with the best quality service and the most perfect products. Our professional, fast customer service can meet the various requirements of your project and provide you with the most professional rivet solutions.

Because we have been producing and selling peel rivets for more than ten years, we have customers all over the world. If you demand quality and excellent service from peel rivets, then we are the most suitable partner for you.

What is a Peel Rivet?

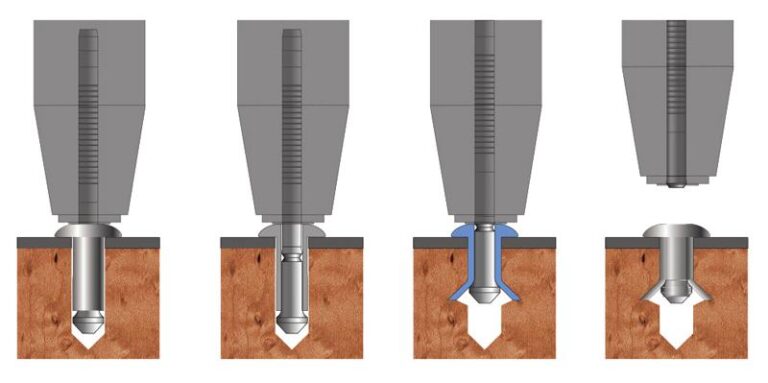

Peel Rivets are a special type of blind rivet. The design features a tail that splits into multiple “petals” or “tabs” during the riveting process, creating a larger contact area on the backside of the material. This structure effectively spreads the load and reduces stress concentrations, making it particularly suitable for joining thin, fragile and soft materials.

How Do you Install Peel Rivets?

Where to Buy Peel Rivets?

Obviously! We can supply all types of peel rivets for your project.Rivmate’s prices are a third or less of the retail price. Of course, as a peel rivets manufacturer, we have a minimum order requirement. (MOQ 50,000)

The unit price is actually much lower than your purchase price from local. You will get more profit when you choose us to buy peel pop rivets!

What is the Difference Between Peel and Pop Rivets?

| Comparison Item | Peel Rivets | Pop Rivets |

| Tail Design | Pre-split tail that splits into “petals” | Tail deforms into a “bulge” without splitting |

| Stress Distribution | “Petals” distribute stress, reducing concentration | Bulge provides clamping force, less stress distribution |

| Suitable Materials | Thin sheets, fragile materials, and soft materials | Wide range of materials and thicknesses |

| Primary Applications | Automotive interior panels, appliance housings, thin sheet connections | Automotive body panels, construction panels, electronics, furniture manufacturing |

| Installation Tool | Standard rivet tool | Standard rivet tool |

| Aesthetic Quality | Smooth finish with evenly distributed petals | Smooth finish with bulge at the back |

How to Choose the Right Peel Rivets for your Project?

I. Substrate Type Determines Suitability for Peel Pop Rivets

Peel Pop Rivets are suitable for soft or low-strength substrates unable to withstand high concentrated loads, such as engineering plastics like ABS, PVC, and PP; fiberglass-reinforced plastic (FRP); composite sandwich panels; and extremely thin aluminum or wood sheets. These materials possess limited strength but exhibit dimensional stability within their plane.

Standard blind rivets concentrate loads on a tiny rear area during installation, often causing material cracking or pull-out. Peel Pop Rivets expand through “flowering” at the tail, significantly increasing the rear bearing area to distribute loads and reduce localized stress. In non-load-bearing or light-load structures, their failure risk is typically lower than that of high-strength blind rivets.

II. Grip Range Determines Flowering Quality

The grip range of Peel Pop Rivets directly determines whether the tail can achieve full flowering. When the total material thickness approaches the upper or lower limits of the grip range, the risk of incomplete petal expansion increases significantly, resulting in insufficient backing support area.

For applications with a total thickness of 4.0 mm, prioritizing a grip range of 3.0–6.0 mm over 4.0–5.0 mm provides sufficient deformation space for tail expansion. This creates a more symmetrical and stable formed structure, enhancing consistency in batch installations.

III. Diameter Determines Load Distribution, Not Ultimate Strength

In Peel Pop Rivets, increasing diameter primarily expands the pop-up radius to enhance backing support area, rather than linearly boosting strength. Larger diameters distribute loads more evenly, making them more suitable for soft substrates.

Under identical load conditions, increasing diameter from Ø4.0 mm to Ø4.8 mm reduces stress per unit area on the backing by approximately 25–35%. Therefore, where appearance and weight allow, prioritizing larger diameters significantly reduces the risk of tear failure in plastics and composites.

IV. Material Selection Must Match Environment and Long-Term Stability

Peel Pop Rivets commonly use aluminum shells with steel cores, enabling stable popping and consistent tear-off performance suitable for most indoor or general-environment applications.

In humid or corrosive environments, assess material compatibility between the rivet and substrate to prevent corrosion or performance degradation due to potential differences. For outdoor or semi-outdoor applications, prioritize material combinations with more stable corrosion resistance to ensure long-term reliability.

With so many different types of peel pop rivets on the market, it can be difficult to find the one that is exactly right for your project, Rivmate’s philosophy is “We’re not just a rivet supplier, we’re a rivet solution provider“.

If you are not sure which size of peel rivets is right for your business, please contact our engineers for a customised solution!

FAQs – Peel Pop Rivets

1. What Are Peel Pop Rivets Used For?

Peel pop rivets are primarily used for joining low-strength, soft, or brittle materials such as plastics, fiberglass, rubber, composites, thin wood panels, and honeycomb structures.

During the riveting process, the rivet’s tail “blooms” to form multiple support claws, creating a large load-bearing area on the backside. This significantly reduces the risk of material tearing or crushing.

2. How Do Peel Rivets Differ from Standard Blind Rivets?

Unlike conventional blind rivets that create a single bulge on the backside, Peel Rivets unfold evenly along pre-cut slots when the mandrel breaks, forming a multi-petal structure.

This configuration distributes tensile forces across a larger contact area, making it particularly suitable for applications where the backside is inaccessible or the substrate has limited load-bearing capacity.

3. Which Materials Are Best Suited for Peel Pop Rivets?

Peel Pop Rivets are most suitable for the following materials:

- Plastics and thermoplastics

- Fiberglass Reinforced Plastics (FRP) and composites

- Thin wood panels, particleboard, MDF

- Honeycomb panels, foam core panels

Not recommended for high-load steel structures or metal-to-metal connections requiring high shear strength.

4. What Are the Main Advantages of Peel Rivets?

Key benefits include:

- Large backing support area: Effectively prevents material tearing

- Reduced local stress concentration: Protects brittle or soft substrates

- Single-side installation: Suitable for enclosed structures

- High installation stability: Greater adaptability to hole diameters and material thicknesses

Thus, they are widely adopted in enclosures, decorative components, and lightweight structures.

5. Are Peel Pop Rivets Suitable for Waterproof Applications?

Under standard conditions, peel rivets are not inherently waterproof. To enhance waterproofing or sealing performance, consider incorporating:

- Closed-end rivet structures

- Sealing washers or sealants

- Aluminum or stainless steel materials to reduce corrosion risk

Specific sealing ratings require validation based on actual operating conditions.

We Can Help You!

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com