pop rivet black anodized

Pop Rivet Black Anodized is a very common finish. Black anodized blind rivets are surface treatment products that are electrolytically oxidized, then dyed black and sealed for aluminum blind rivets. This process forms a dense protective layer of aluminum oxide on the surface of the rivet, which significantly improves its corrosion resistance, abrasion resistance and UV resistance, and at the same time gives it a uniform and beautiful black appearance. Widely used in architectural curtain walls, electronic equipment shells, automotive interiors and other fields, both lightweight, high strength and decorative features.

Why pop rivets need to be black anodized?

The use of rivets in demanding assembly environments often requires both functionality and aesthetics. Black anodizing not only enhances the structural protection of blind rivets, but also expands their application in the high-end assembly market.

- Improve corrosion resistance

- Enhances surface hardness and abrasion resistance

- Provides a consistent, low-reflective black appearance

- Provides insulating properties

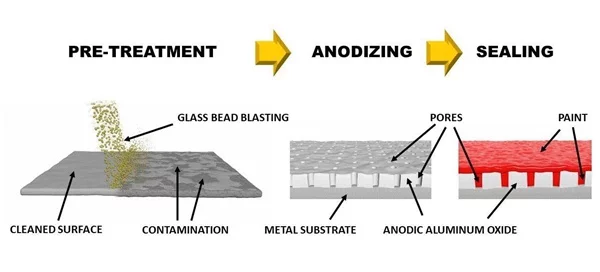

Black Anodized Process Overview

When black anodizing rivets, it is necessary to ensure that the oxidized film layer is uniform, the dye is full and the holes are sealed thoroughly, in order to achieve stable protection and appearance.

1. Pre-treatment

- Degreasing and Degreasing: Use alkaline cleaner (e.g. NaOH) to remove oil, oxidized skin and particles from the rivet surface.

- Water washing and rinsing: Thoroughly remove residual alkaline solution to avoid cross-contamination.

- Chemical etching (optional): Lightly etch the surface to form uniform roughness and improve film adhesion.

2. Anodizing

- Electrolyte formulation: 15-20% sulfuric acid solution (H₂SO₄) is commonly used in industry.

- Voltage control: Maintain at 12-20V, typical value is 15-18V.

- Temperature control: Reaction tank temperature is controlled at 15-25°C to maintain uniform growth of the oxide film.

- Time control: 6-30 minutes, depending on the film thickness required (typically 10-25μm).

3. Black Dyeing

- Dyeing method: organic dyes (commonly acid black dyes) or

Inorganic dyes (metal deposition method). - Temperature and time: 40-60°C, dyeing time 5-15 minutes, adjustable depending on color concentration.

- Stirring and flow rate control: keep the uniformity of liquid and prevent color difference.

4. Sealing

In order to close the anode film pores, lock in the dye and enhance the corrosion resistance of the rivets. The following two methods are often used to do this:

- Hot water sealing (95-100°C, 10-20 minutes): common and environmentally friendly.

- Nickel salt sealing: good sealing, suitable for outdoor grade rivets.

5. Drying and quality control

Drying method: hot air drying or natural air drying.

Testing items:

- Appearance consistency (no color leakage, no blistering)

- Film thickness (10-25μm, according to ISO 7599 or MIL-A-8625)

- Corrosion resistance test (e.g. ASTM B117 salt spray ≥ 336 hours)

Applications of Black Anodized Blind Rivets

- Architectural and curtain wall systems: for the connection of aluminum panels, honeycomb panels, aluminum composite panels and other facade structures. The black anodized layer can maintain visual unity with black profiles or dark finishes, preventing rivets from becoming a visual distraction.

- Consumer electronic products: It is suitable for the assembly of components such as laptop shells, stereo bodies, communication equipment and so on. The anodized black color is beautiful and wear-resistant, matching the overall industrial design style.

- Automotive interiors and lightweight structures: for instrument panels, door trims, interior linings and other parts. Taking into account the needs of aesthetics, corrosion resistance and lightweight, it is widely used in aluminum alloy structural components.

- Aerospace and transportation equipment: suitable for lightweight skin connections and non-load-bearing parts. Black anodizing has a strong environmental adaptability, to meet certain corrosion resistance and insulation requirements.

- Industrial equipment and electrical control boxes: for panels, housings, brackets and other assemblies. The black surface reduces reflective interference and meets the requirements for insulation and durability.

Material Compatibility & Limitations

There are certain material compatibility requirements and process application limitations when black anodizing blind rivets.

- Material compatibility: Only aluminum blind rivets (e.g. 5052, 5056) are suitable for anodizing. 5056 > 5052 > 5005 (dye consistency from highest to lowest).

- Structure and Shape Limitations: The inner cavity in the core-pull structure may be incompletely sealed due to electrolyte residue, it is recommended to design an impermeable structure or post-cleaning treatment.

- Limitations of process adaptation: the anode membrane is brittle, it is not suitable for high-temperature post-treatment or hot riveting operation, cold riveting or temperature-controlled riveting equipment is required.

- Color consistency limitations: the same batch processing, the same alloy grade rivets integrated processing, in order to avoid the problem of color difference.

Black anodizing is suitable for blind rivets in all-aluminum configurations, but requires attention to structural design, electrical requirements and batch control to ensure consistent performance and appearance. Special compatibility verification strategies are available for composite materials or different industry specifications.

Available Sizes & Standards

Rivet Size Examples:

- 3/32“, 1/8”, 5/32”, 3/16”

ANSI/IFI, DIN, ISO dimensions can be listed.

Available head styles

- round

- countersunk

- large flange

| Metric Size (mm) | Imperial Size (inch) | Grip Range | Common Head Styles | Recommended Aluminum Alloy |

|---|---|---|---|---|

| 2.4 × 6 | 3/32″ × 1/4″ | 0.5–3.0 mm | Dome, Countersunk (CSK) | 5052 / 5056 |

| 3.2 × 8 | 1/8″ × 5/16″ | 1.0–4.0 mm | Dome, CSK, Large Flange (LF) | 5056 preferred |

| 4.0 × 10 | 5/32″ × 3/8″ | 2.0–6.0 mm | Dome, Large Flange | 5056 |

| 4.8 × 12 | 3/16″ × 1/2″ | 3.0–8.0 mm | Dome, CSK, Large Flange | 5056 (high strength) |

| 6.4 × 16 | 1/4″ × 5/8″ | 4.0–10.0 mm | Dome, Large Flange | 5056 (structural grade) |

Surface Treatment Comparison – Black Anodized Pop Rivet vs. Alternatives

| Attribute | Black Anodized | Black Painted (Powder) | Black Zinc Plated | Clear/Color Anodized |

|---|---|---|---|---|

| Base Material | Aluminum only | Aluminum, steel | Carbon steel only | Aluminum only |

| Corrosion Resistance | ★★★★☆ (sealed oxide layer) | ★★★☆☆ (depends on coating integrity) | ★★★☆☆ (chemical passivation) | ★★★☆☆ (good, less UV protection) |

| Wear Resistance | ★★★★☆ (ceramic-like oxide) | ★★☆☆☆ (coating may scratch) | ★★★★☆ (hard metal plating) | ★★★☆☆ |

| UV / Outdoor Durability | ★★★★☆ (very stable) | ★★★★☆ (if polyester powder used) | ★★☆☆☆ (black zinc fades over time) | ★★★☆☆ (natural anodized) |

| Aesthetic Appearance | Matte or semi-gloss, deep black | Gloss, matte, textured possible | Shiny or dull black, may vary | Silver, gold, bronze, etc. |

| Coating Thickness | 10–25 μm (precise) | 60–100 μm (varies) | 5–15 μm | 10–25 μm |

| Electrical Conductivity | Non-conductive | Non-conductive | Conductive | Non-conductive |

| Process Limitations | Only for aluminum, surface must be clean | Risk of peel or chip under force | Not for aluminum, environmental burden | Limited color depth vs. dyed finishes |

| Best Use Cases | Electronics, aerospace, architecture | Decorative, indoor, low-impact use | Structural steel fasteners, cost-driven | General-purpose aluminum hardware |

Black Anodized is the best balance of durability and appearance for aluminum rivets, especially in exposed or corrosive environments.

Black Painted rivets offer flexibility in color and finish but are less durable under abrasion or mechanical stress.

Black Zinc Plated is preferred for steel rivets where cost and hardness matter more than UV or long-term appearance.

Clear Anodized suits applications where appearance is secondary to light corrosion resistance.