Table of Contents

I know you may be wondering if pop rivets are right for you your fiberglass project.

If so, please read this guide. It covers everything about fiberglass pop rivets. From benefits, preparation before riveting fiberglass, uses to categorizing fiberglass pop rivets and how to choose pop rivets for fiberglass.

Let’s explore it together!

Table of Contents

What are Fiberglass Pop Rivets?

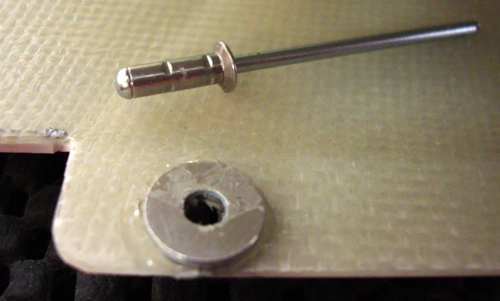

Fiberglass Pop Rivets are blind rivets specifically designed for use with fiberglass (Fiberglass) materials. They are typically made of aluminum, stainless steel, nylon, or specialized composites and are designed to provide a strong and reliable connection in brittle or low-strength substrates such as fiberglass sheets, composites, and other materials.

Fiberglass pop rivets can provide connections that will not damage or crack the fiberglass structure. It is lightweight, strong, corrosion resistant and easy to install.

Advantages of Pop Rivets for Fiberglass

- No damage to the fiberglass: Pop Rivets are connected by “pull rivets”, which do not generate rotational stresses, thus reducing the risk of cracking.

- Suitable for one-sided operation and easy installation: Pop Rivets require operation on one side only, without touching the back of the riveted joint, which is advantageous for many fiberglass structures (e.g., boat hulls, RV panels).

- High Strength & Good Vibration Resistance: Fiberglass is often used outdoors or in high strength environments. These applications require connectors that are vibration and shock resistant, otherwise they are prone to loosening or breaking.

- Corrosion Resistant for Wet & Outdoor Environments: Fiberglass is commonly used in outdoor and wet environments (e.g., boats, RVs, industrial equipment, etc.) where traditional metal fasteners may rust or corrode!

- Strong Connections for Composite Structures: Pop Rivets are suitable for joining different materials and provide strong riveted connections.

- Lightweight for Aerospace & Automotive applications: Aluminum or Nylon Rivets Lightweight and durable, keeping the overall structure lightweight.

- Cost-effective and reduces maintenance costs: Rivets are the most cost-effective option compared to other joining methods.

As you can see, there are many reasons why you should choose pop rivets for fiberglass project.

Do You Have Any Questions?

Let Us Solve Your Problem

Limitations of using pop rivets for fiberglass

While Pop Rivets offer many advantages on fiberglass materials, in some cases they may not be the best choice.

Cannot be disassembled, not suitable for parts requiring frequent maintenance

Once installed, Pop Rivets are difficult to remove and must be removed with a drill or cutting tool. This is a disadvantage for applications that require periodic maintenance, adjustments or replacement parts.

May cause galvanic corrosion

When the rivet material (e.g., aluminum or stainless steel) comes into contact with the metal support structure inside the fiberglass (e.g., aluminum or steel frame), galvanic corrosion may occur, resulting in corrosion of the metal parts and material deterioration.

Fiberglass thickness may affect riveting results

Pop Rivets are available for a range of material thicknesses (Grip Range), if the fiberglass is too thin, it may not provide enough clamping force, if it is too thick, the riveting may not be complete or the connection may not be secure.

How to Use Pop Rivets on Fiberglass?

There are a few things to keep in mind when installing fiberglass material with pop rivets.

Using the correct method of riveting allows for a more secure connection. For excellent results, you should follow these steps:

Choosing the right rivet

First start by choosing the right type of rivets, material for your fiberglass project.

Choose the type of rivets that have a large force area, such as large flange rivets, multi grip rivets and tri fold rivets.

Preparation of fiberglass material

Prepare the fiberglass material to be riveted. Include:

- Measuring Fiberglass Thickness

- Marking Rivet Locations

- Apply tape to the drilled holes (Mylar tape is recommended)

drilling

Tungsten carbide or high speed steel (HSS) drill bits are recommended to minimize fiberglass chipping.

Drill size should be slightly larger than the rivet diameter by 0.1-0.2mm to avoid inserting the rivet too tightly or too loosely.

Installation of rivets

- Insert Rivet: Insert the rivet into the drilled hole to ensure that the cap brim fits perfectly on the fiberglass surface.

- Add spacer (optional) if desired: add a nylon or metal spacer to the head or back of the rivet to distribute the pressure and reduce the risk of fiberglass breakage.

- Riveting with a Rivet Gun: Select a suitable manual or pneumatic rivet gun. Ensure that the nozzle of the rivet gun is fully seated on the head of the rivet, at a vertical angle, to avoid skewing and uneven riveting. Slowly pull the handle or press the trigger until the mandrel breaks.

- Check the quality of the riveted joint: make sure that the rivet is firm and not loose, and that there are no cracks or delamination on the surface of the fiberglass.

Inspection and amendment

- Visual inspection” ensures that the rivet cap edge is tight against the fiberglass with no gaps. There are no cracks, distortion or delamination of the fiberglass surface.

- Manual test (slight pulling or tapping of the rivet) “ensures that the rivet is securely fastened without loosening or slipping.

Do You Have Any Questions?

Let Us Solve Your Problem

Types of Pop Rivets for Fiberglass

Currently, you can choose from a wide range of Blind Rivets on the market.

- Large Flange Head Blind Rivets

- Multi Grip Blind Rivets

- Closed End Blind Rivets

- Tri Fold Rivets

- Bulb Tite Blind Rivets

- Aluminum Rivets

- Stainless Steel Rivets

- Plastic Rivets/Nylon Rivets

How to Choose the Best Pop Rivets for Fiberglass?

Before choosing pop rivets for your fiberglass project, you have to consider many factors before you can choose the best fiberglass pop rivets for your business.

Ⅰ. Available budget

There are many types of blind rivets that can be applied to fiberglass material and their prices vary greatly.The price of Fiberglass pop rivets varies depending on the type of rivet and material.

The budget at your disposal will determine the type of rivet you choose.Large flange head pop rivets can be much more expensive than dome head rivets, and multi grip blind rivets can be much more expensive than standard blind rivets. And inexpensive pop rivets may ruin the quality of your project.

- When budget is limited → choose aluminum rivets (cost effective and suitable for most fiberglass connections)

- High strength needs → choose stainless steel rivets (costly, but best performance)

- Low load + cost sensitive projects → choose plastic rivets (cost effective, protects fiberglass surfaces)

Ⅱ. Areas of application

Different fiberglass applications have different requirements for rivets in terms of strength, corrosion resistance, sealing, etc., and therefore require targeted selection.

- Underwater or wet environment → choose closed type rivets + corrosion-resistant materials

- Impact-prone areas → choose a rivet with a large brim to distribute the pressure.

- Projects that require flexibility → Choose rivets with multiple clamping ranges to accommodate different thicknesses.

Ⅲ. Selecting the correct pop rivet size

You need to choose the rivet size based on the thickness of the material you want to fiberglass and the pre-drilled holes.

Pop rivet grip range: The grip range of the rivet should be slightly greater than the measured thickness.

Rivet Diameter: The drilled hole diameter should be 0.1-0.2mm larger than the rivet diameter for smooth installation.

- Thin-walled fiberglass (<4mm) → use 3.2mm (1/8″) rivets

- Thicker fiberglass (>6mm) → use 4.8mm (3/16″) rivets.

- If higher strength is required → use 6.4mm (1/4″) rivets, but prevent the glass fibers from breaking!

Ⅳ. Choice of waterproofing or sealing options (optional)

If the fiberglass structure needs to be waterproof (e.g., marine, outdoor equipment), you can choose Closed-End Rivets or apply a sealant (Sealant) during installation to improve the waterproof performance.

Specific Applications of Pop Rivets for Fiberglass

You can use this coating on many fiberglass applications, for example:

- Marine and offshore industry: decks, hatches, hatches for fiberglass hulls.

- Motorhome (RV) and Camper (Camper) manufacturing: exterior fiberglass panel fastening for motorhomes. Roof racks, window frames and vent installations. RV interior fiberglass component attachments (e.g. cabinets, seat brackets).

- Automotive, Truck and Specialty Vehicle Manufacturing: Fiberglass body and trim fixings (e.g. bumpers, spoilers, roofs). Truck and van fiberglass compartment splicing. Fastening of interior structural components made of fiberglass (e.g., dashboards, door panels).

- Architectural curtain walls and decorative panels: glass fiber reinforced composite (GFRP) curtain wall fixing. Installation of decorative panels made of fiberglass (e.g. acoustic panels, facade guards). Fiberglass ceiling, canopy or ventilation system fixing.

- Electronic equipment housings and enclosures: fixing of fiberglass electrical cabinets, enclosures and control panels.

- Industrial equipment and machinery enclosures: fiberglass shields, industrial equipment enclosure splicing.

FAQs about Pop Rivets for Fiberglass

Pop Rivets vs screws: which is better for fiberglass?

This needs to be chosen according to the requirements of your application. If your project requires high strength, vibration resistance, durability, and a connection that does not require disassembly, then pop rivets are excellent choices.

Screws are better if you need a fixing that is removable, easy to maintain and simple to install.

If unsure, use a combination: use Pop Rivets in critical stress areas and screws in auxiliary areas for optimal fastening.

How to Remove Fiberglass pop rivets?

Rivets are permanent connections, so the only way to remove rivets is to remove them by destroying the rivet structure. Removal of rivets requires the use of an electric drill with a bit slightly larger than the rivet diameter.

Conclusion

As you can see, pop rivets for fiberglass is an excellent solution.

At Rivmate, we use state-of-the-art machinery to produce pop rivets.

Get Rivets Quote

Buy Open Type Blind Rivets

Buy Structural Blind Rivets