Table of Contents

Rivet vs nail is something that many business owners need to know before buying a rivet or nail. This article gives you a detailed overview of the differences between a rivet and a nail.

Table of Contents

What is a Rivet?

A rivet is a mechanical fastener used to permanently join two or more workpieces. A rivet is usually made of metal, including aluminum, steel, stainless steel, and other materials. It consists of a bar with a head and an end that is firmly secured to the workpiece by inserting it into a pre-drilled hole and then deforming or expanding the end. Rivets are widely used in manufacturing, construction, and aerospace industries, and are especially suited for applications where high strength and durable connections are required.

There are many types of rivets, including solid rivets, hollow rivets, semi-hollow rivets, blind rivets and structural rivets. Rivets can provide your project with high strength, good durability, excellent vibration resistance and consistent reliability.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

What is a Nail?

A nail is the most commonly used mechanical fastener for holding two or more objects (usually wood) together. It is usually made of metal in the shape of an elongated rod with a sharp end and a flat or slightly curved head at the other end. The sharp end of the nail is inserted into the material by hammering or other tools to hold it in place.

There are many different types of nails including Common Nail, Box Nail, Finishing Nail, Flooring Nail, Ring Shank Nail and Screw Nail.

Difference of Rivet and Nail

Plus down let’s look at rivet vs nail in detail. fully understand the difference between rivet and nail.

1. Rivets vs Nails:Design and Structure

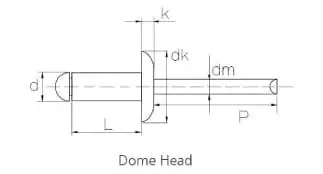

A rivet consists of a rivet head and a rivet stem. It has a broad head at one end to provide holding power and support. The other end, is deformed or expanded to hold the rivet during installation.

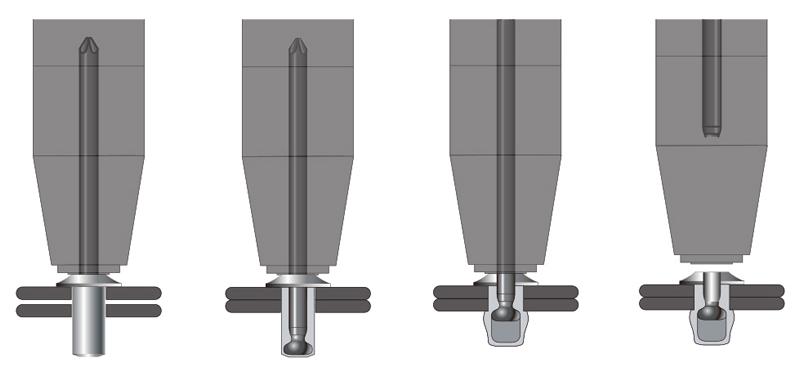

Holes need to be drilled in the connecting material for insertion of rivets prior to installation. The end of the rivet is then deformed by a tool such as a rivet gun to expand and secure it in the hole, forming a tight connection. The rivets form a permanent connection after installation and are not easily removed.

The construction of a nail is as simple as it gets. It has a flat or slightly curved head at one end for hammering. The main part is usually a slender rod. The other end of the nail is very sharp and is used for insertion into the material.

When using nails, there is no need to pre-drill holes and they can be hammered directly into the material. Nails can be used for temporary or permanent connections and are relatively easy to pull out with tools.

2. Rivet vs Nail: Installation Method

There is a significant difference between Rivet and nail in terms of installation methods.

Prior to installing rivets, holes matching the rivet diameter need to be drilled in the material to be joined, and then a specialized riveting tool is used to complete the rivet installation process. Nails, on the other hand, only require the use of a hammer or nail gun to directly strike the head of the nail to complete the installation.

If you want to know more about installing rivet, you can read this article “How to Install Pop Rivet“.

3. Rivet vs Nail: Application

There is also a big difference between rivet and nail in terms of usage scenarios.

Rivets provide a strong and permanent connection. Ideal for connections that require high strength, durability and reliability, such as in aerospace, automotive manufacturing, construction and bridges, metal fabrication and more.

Nails, on the other hand, are quicker and more flexible to install. It is suitable for applications that require quick and easy installation and removable connections, such as construction and carpentry, furniture manufacturing, decoration, packaging and transportation, DIY and handicrafts.

This article describes the application of rivets.”Applications of Blind Rivets“.

4. Rivet vs Nail:Strength and Durability

Normally, nails are not as strong as rivets.

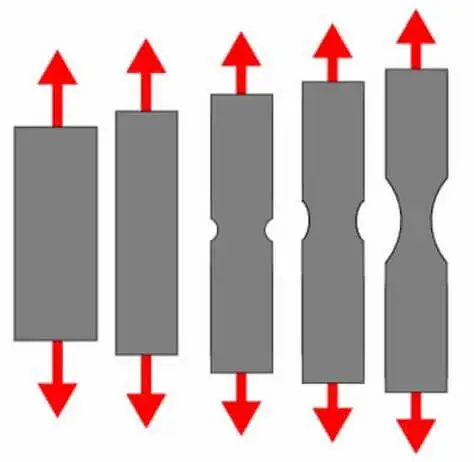

Rivets are fastened by deformation or expansion during connection, which improves high tensile and shear strength. And the head of the rivet can uniformly disperse the stress, reducing the stress of the material several kinds, and enhancing the stability of the overall structure. And the strength of the nail depends on the type of nail, usually possesses lower tensile and shear strength.

In addition to this, the rivets will form a permanent connection after installation, not easy to loosen. The nails are then easily removable.

Rivet vs Nail:Working Principle

Rivets are used to form a tight connection by applying pressure to the end of the rivet, causing the end to deform or expand. The tail of the rivet deforms under pressure to form a new head that holds the material securely between the two ends of the rivet.

Instead, the nails are held in the material by friction on the surface of the material and by the shape of the nail. The head of the nail will provide additional support to prevent the nail from pulling out of the material.

Rivet vs Nail: Material suitability

In industry, a lot of pop rivet is used because rivet can be adapted to various materials. Whether metals, plastics, composites or sheet materials, rivet can be used to connect materials. Unlike nails, which have a relatively low strength, there is no way to connect metal materials. In everyday applications, nails are widely used in wood, plasterboard, fiberboard, plywood and lightweight materials.

All in all, rivets not only provide a stable connection for metal materials, but also provide a strong connection for lightweight materials. However, nails are only suitable for joining wood or lightweight materials.

Rivet vs Nail: Permanent Connection

Typically, rivets are considered by engineers to be permanent connections. If you want to remove a rivet, you have to destroy the structure of the rivet, and there is no way to reuse it. But nails are different, they are designed to be very flexible. And it’s very easy to remove, requiring only a pry bar or other tool to pull it out without damaging the material.

If your interested in whether rivets are a permanent connection, read this article.”Are Rivets Permanent“.

Rivet vs Nail:Cost

The cost difference between Rivet and nail is mainly in the cost of materials, installation tools and equipment.

In terms of material cost, rivets are usually made of high-strength metals such as aluminum, steel, and stainless steel, which cost more. While nails are usually made of steel, iron and other metals, the cost is lower.

From the point of view of the tools used, the installation of rivets requires the use of specialized tools, such as manual rivet guns, pneumatic rivet guns or electric rivet guns. These tools are more costly, especially the high-end pneumatic or electric equipment. Whereas, installing nails only requires a hammer, which is quite inexpensive.

Rivets cost a lot more than nails, but they will be stronger. So you have to give to choose the right connecting fasteners according to the requirements of your project.

How Much Do Rivets Cost?

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Rivet vs Nail : Difference Between Rivets and Nails

There are still a lot of differences between rivets and nails, and I’ve included a detailed comparison of their differences in the table below.

| Aspect | Rivet | Nail |

| Design Structure | Composed of a head and a deformable tail; fixed by deforming or expanding the tail | Composed of a long, slender shaft with a pointed end and a flat or slightly curved head; fixed by driving into material |

| Installation Method | Requires pre-drilled holes; fixed using a rivet gun to deform the tail | Driven directly into material with a hammer or nail gun; no pre-drilling needed |

| Application Scenarios | Aerospace, automotive manufacturing, construction and bridges, metalworking, electronics and appliance manufacturing | Construction and carpentry, furniture manufacturing, interior decoration, packaging and shipping, DIY and crafts |

| Strength | High tensile and shear strength; suitable for high-stress and vibration environments | Lower tensile and shear strength; suitable for lighter loads and softer materials |

| Working Principle | Fixed by deforming or expanding the tail, creating a permanent connection | Fixed by friction; head provides additional support; can be temporary or permanent |

| Suitable Materials | Metals (steel, aluminum, stainless steel), plastics, composites, thin sheet materials | Wood, drywall, fiberboard, plywood, lightweight materials |

| Permanence of Connection | Forms a permanent connection; difficult to remove, requires drilling out or destruction | Can be temporary or permanent; easy to remove and adjust, suitable for applications needing flexibility |

| Cost | Higher material cost, specialized tool cost, longer installation time, requires skilled labor | Lower material cost, simple tool cost, quick and easy installation, no special skills required |

Clonclusion

We covered the vast majority of the differences between rivet and nail. Including their structure, how they work and usage scenarios. In addition, we have listed and organized the differences between rivet and nail into a table. Be sure to check out the differences so you can choose the right fastener for your project.

Explore Rivmate's High Quality Blind Rivets

Rivmate is a pioneer in the manufacture of blind rivets. From the manufacture of standard blind rivets to the design and customization of high-strength structural rivets, our line of rivets is one of diversity and excellence. Inspected under a 13-step inspection process, our rivets redefine quality and value for money. We can offer you the most affordable rivet solutions.

Our premium customers are located all over the world. As a result, you will always get the product and price that best fits your market.