Table of Contents

Automobile bodies are often attached using rivets. So do you know what are car body rivets and how to riveting car body panels?

Through this article, you will learn the concept of car body rivets and the specific use scenarios.

Table of Contents

What are Car Body Rivets?

Car Body Rivets are rivets that are specifically used in the manufacture and repair of car bodies. These rivets are usually used to join different metal plates, components or other materials on the car body, and common materials include aluminum, steel and stainless steel. Car Body rivets are widely used in the automotive industry. For example, structural connections in body frames, doors, roofs, and chassis.

Features of auto car body rivets:

- Body rivets provide strong connection strength to withstand the vibration, pressure and impact of vehicles.

- Body rivets are usually made of corrosion-resistant materials to prevent corrosion in wet or harsh weather conditions.

- Durability: Rivets are usually highly resistant to aging and durable for long-term use.

- No damage to the body surface

Types of Car Body Rivets

There are many types of rivets that can be used for car bodies. Each type has different characteristics and application scenarios and are usually chosen based on the strength required, the type of material and the installation method. Here are some common types of rivets used for auto body panels.

Blind Rivets for Car Body Panels

Blind rivets are widely used in automotive body panels. Especially some difficult to access or need to install one-sided offset, the blind rivet is very ideal solution. The specific application scenarios of blind rivets in automotive body panels are as follows:

- The connection of automobile exterior body panels: doors, hoods, roofs, wings and side panels, etc.

- Fixing interior door panels, window frames or window glass brackets.

- Door interior panels

- Body frames, sunroofs, etc.

- Attachment of accessories such as lamp brackets, reflector brackets, emblems, windshields, etc.

Structural Rivets for Car Body Panels

The application scenario of structural rivets in automotive body panels mainly involves those parts that require high strength of connection, especially in ensuring the strength, rigidity and crash safety performance of the body. Structural rivets are used for joints that are subjected to high loads and impacts. It provides a durable and solid connection. Below are some specific applications for structural rivets in body panels:

- Brackets for bodywork, girder connections

- Chassis to body panel connection

- Connection of the components of the crash beam

- Connecting door outer panels to door frames

Rivets Nuts for Car Body Panels

Rivet Nut‘s role in automotive body panels is primarily to provide an internally threaded connection, enhance the structural strength of the body, and ensure a strong and reliable connection in place. Below are some typical applications of rivet nuts in automotive body panels:

- Provides female threaded connections during door manufacturing for mounting door handles, window frames and other accessories.

- Provides strong female threaded connections in thin-walled body panels

- Provides a strong connection point for exterior accessories that can be removed and installed multiple times

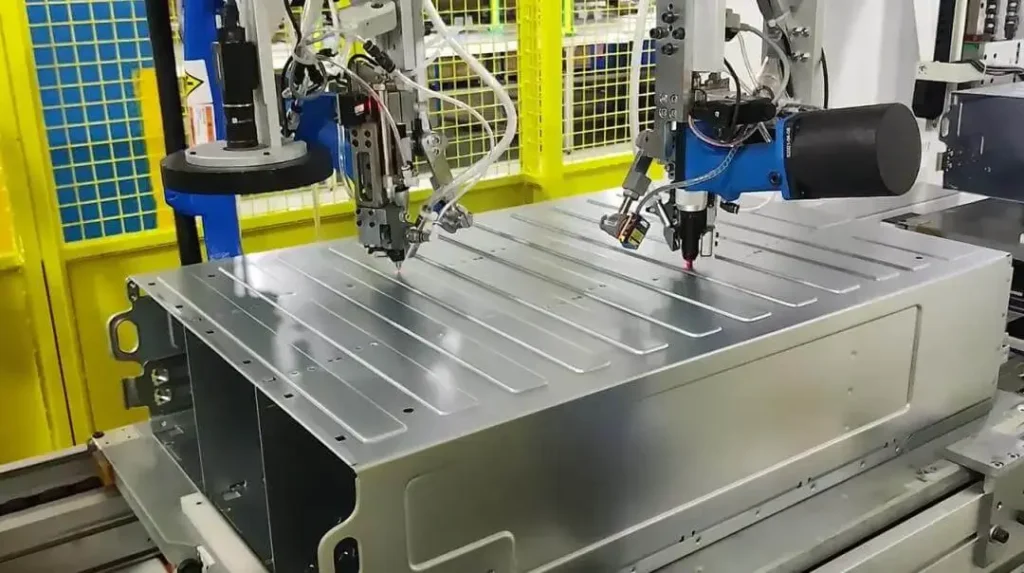

Self Piercing Rivets for Car Body Panels

Self-Piercing Rivets (SPR) is an efficient joining technique commonly used in automotive manufacturing. Self piercing rivets are used very frequently in the assembly of body panels. Compared with traditional riveting or welding methods, self-piercing rivets can be applied by riveting two layers of metal panels together directly, without the need for pre-drilling, which has greater application advantages. The application of self-pierce rivets in automotive body panels is mainly reflected in the following aspects:

- Body Frame to Outer Panel Joints

- Door panel to frame connection

- Window frame to body panel connection

- Connection of crash beam and body panel

- Roof sunroof frame and body panel connection

- Connection of underbody guards to body panels

- Connection of multi-layer body panels (e.g. connection of body frame and roof)

Do You Have Any Questions?

Let Us Solve Your Problem

How to Riveting Car Body Panels?

Both riveting and welding are used frequently in auto body repair. Both methods have their advantages and disadvantages. The choice of which method is more appropriate then depends on the specific needs and circumstances of the repair.

Riveting vs Welding: Which is Better for Auto Body Repair?

Both riveting and welding are used frequently in auto body repair. Both methods have their advantages and disadvantages. The choice of which method is more appropriate then depends on the specific needs and circumstances of the repair.

Pros and Cons of Welding for Car Body

Pros

- High strength: welding can provide higher connection strength than riveting, which is suitable for parts subject to high pressure and stress.

- Good sealing: Welded joints are continuous without gaps, which can effectively prevent water, gas or other substances from penetrating and ensure sealing.

- Structural consistency: welded joints are completely fused and can maintain the integrity of the raw material without affecting the strength of the material.

Cons

- Specialized equipment and skills required: Welding requires specialized welding equipment and trained mechanics, which may increase repair costs for some vehicle owners or garages without welding facilities.

- Thermal effects: The high temperatures generated during the welding process may cause deformation or damage to the metal in the surrounding area, especially for thin sheet materials, which may affect the appearance or strength of the bodywork.

- Higher time cost: The welding process requires more time and steps, especially for complex repair work.

Pros and Cons of Riveting for Car Body

Pros

- Simple installation: the installation process of rivets is relatively simple, can be completed using a rivet gun, does not require specialized welding equipment, lower maintenance costs.

- Suitable for thin plate materials: rivets do not require high-temperature operation, suitable for use in thin plates or materials susceptible to thermal damage, avoiding possible thermal damage during the welding process.

- Reduce body deformation: Since rivet installation does not produce thermal effects, body deformation that may be caused by welding can be avoided. This feature is especially important when dealing with automotive exterior and body panels.

Pros

- Limited joint strength: Rivets generally have a lower joint strength than welds. Riveted connections may not be as strong as welded connections when subjected to large loads.

- Poor sealing: riveted joints may have small gaps, which are not suitable for parts requiring high sealing, and are susceptible to penetration of external substances.

- Appearance problem: The appearance of rivets is not as flat as welding. In exposed areas of the body, this can affect aesthetics.

Riveting Car Body vs Welding Car Body

| Parameter | Welding | Riveting |

| Suitable Materials | Suitable for most metals, especially steel | Suitable for aluminum, steel, copper, plastic, and thin sheet materials |

| Installation Process | Requires specialized equipment, high technical skills | Simple installation with rivet gun |

| Repair Speed | Slow, requires cooling and handling time | Fast, especially for quick repairs |

| Connection Strength | High, suitable for heavy loads and high-stress areas | Medium, suitable for low to moderate stress areas |

| Sealing Ability | Good, suitable for repairs requiring sealing | Average, may have gaps |

| Suitability | Suitable for complex, heavy, or long-lasting areas | Suitable for aesthetic repairs, thin sheet materials |

Conclusion

- In body frames and structurally significant areas, welding may be a more appropriate choice if high strength or sealing is required in the repair area. For example, welding provides better strength in doors, undercarriages and areas subjected to high forces.

- For exterior restoration or repairs to thin sheet materials, rivets are a more appropriate choice. Rivets do not generate high temperatures, do not affect the strength of the raw material, are less likely to cause deformation, and are easy to work with, making them suitable for exterior body panels and parts that need to be repaired quickly.

Do You Have Any Questions?

Let Us Solve Your Problem

Wholesale Car Body Rivets from Rivmate

Automobiles demand high quality rivets. When purchasing car body rivets, automobile manufacturers usually require PPAP documentation from the rivet manufacturer. Rivmate can provide you with professional PPAP 4 documentation.

Get instant access to samples of rivets that can be used in your car body pane project for testing.