Table of Contents

Mailbox is something that is very commonly used. So do you know how it is installed and fixed? Usually using mailbox rivets. Do you know how to choose rivets for mailbox? Let us learn more!

Table of Contents

What is a Mailbox?

A mailbox is basically a container or device that’s used to receive, send, and store mail. You’ll usually find them on the outside of buildings, and they’re used to receive letters, parcels, and other items from the postal service.

Types of Mailbox

- Mailboxes for physical mail

- Residential Mailbox

- Commercial Mailbox

- Post Boxes

- Cluster Mailbox

Traditional postal mailboxes are usually installed in front of the home or in the garden. They are usually designed so that they are waterproof and burglar proof.

Do You Have Any Questions?

Let Us Solve Your Problem

Types Mailbox Rivets

There are many rivet types that can be used to mount a mailbox. but it depends on the material of the mailbox, the mounting location and the functional requirements. Below are the common rivet types and their specific uses.

Blind Rivets for Mailbox

The single-sided mounting capability of the Blind Rivet makes it ideal for mounting mailbox frames and brackets. And can be installed in a variety of materials (such as aluminum, stainless steel) manufacturing, suitable for outdoor use.

- Mailbox frame: connects the front panel, back panel and frame portion of the mailbox together.

- Bracket Attachment: used to secure the mailbox to a support pole or wall.

Sealed Rivets for Mailbox

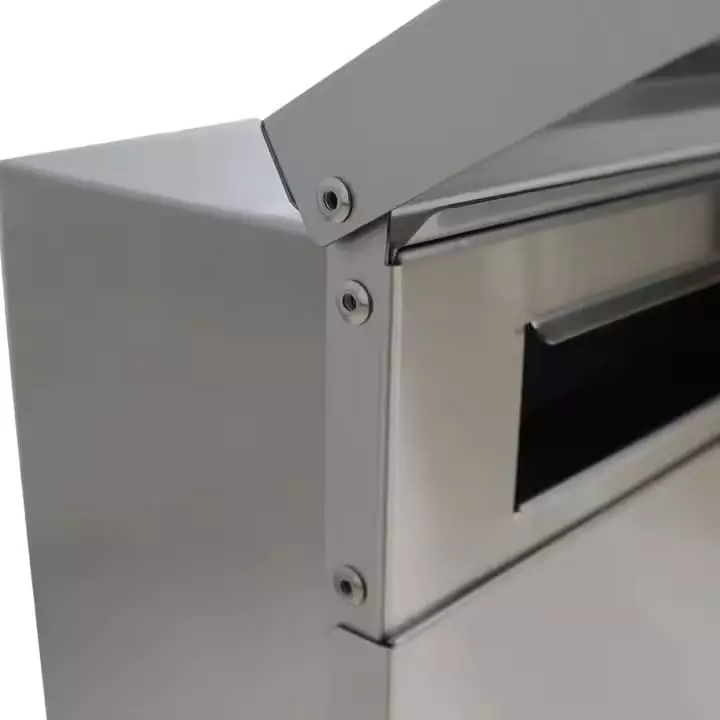

Sealed rivets create a sealed structure when riveted. It can effectively prevent water or air infiltration, perfect for mailbox to be used outdoors. Even if the mailbox is exposed to rainwater, no leakage will occur.

- Mailbox Top: Ensure the joint is waterproof to prevent rainwater from entering.

- Mailbox door: sealing performance to ensure that the inside of the mailbox is dry.

Aluminum Rivets for Mailbox

Aluminum rivets are characterized by light weight and corrosion resistance. This is very friendly for installation in light structures.

- Aluminum Mailboxes: used to connect aluminum components to ensure metal-to-metal compatibility.

- Mailbox Brackets: provide a strong connection without adding extra weight.

Stainless Steel Rivets for Mailbox

Stainless steel rivets are strong and very resistant to corrosion. Therefore it is often used in heavy duty or high stress areas.

- Large or heavy duty mailboxes: e.g. commercial mailboxes or multi-occupancy mailboxes for attaching frames and fixings.

- Coastal mailboxes: for resistance to salt spray corrosion.

Painted Rivets for Mailbox

Painted rivets have rivet heads that are painted or tinted to match the exterior color of the mailbox.

- Decorative panels: on front panels or exterior trim of mailboxes to provide an aesthetically pleasing exterior connection.

- Exterior Trim: To secure nameplates, logos or number plates on mailboxes.

Large Flange Rivets for Mailbox

Large flange blind rivets have a wide head. It can increase the clamping area and prevent material damage, suitable for softer or thinner materials.

- Mailbox door hinges: used to connect the mailbox door to the frame, adding strength and preventing the hinge from coming loose.

- Thin metal or plastic panels: to fix softer materials and prevent cracking due to stress concentration.

Grooved Rivets for Mailbox

Grooved Rivets have a grooved surface that provides a stronger connection in plastic or other soft materials.

- Plastic mailboxes: for securing plastic panels or other composite components.

- Mailbox door frames: to secure softer framing materials.

Multi-Grip Rivets for Mailbox

Multi grip blind rivets have a very wide riveting range. The same size multi grip rivets can be used on a wide range of material thicknesses. If you need to install several different mailboxes, this rivet is perfect for you.

- Mailbox frame connection: suitable for a variety of thicknesses of metal or composite materials to ensure a strong connection.

- Support bar and mailbox base connection: to adapt to different thicknesses of component combinations.

Below I have included a table that shows you in detail how the different types of rivets work. Choosing the right type of rivet not only ensures that your mailbox is structurally sound, but also improves its durability and aesthetics. Making the best choice based on the installation location and environmental conditions is key.

| Rivet Type | Applicable Parts | Reasons for Use |

| Blind Rivets | Frame, Support Brackets | One-side installation, easy operation |

| Sealed Rivets | Top, Door | Excellent waterproof performance, suitable for outdoor use |

| Aluminum Rivets | Aluminum Mailboxes, Support Brackets | Lightweight, corrosion-resistant |

| Stainless Steel Rivets | Large Mailboxes, Coastal Areas | High strength, excellent corrosion resistance |

| Painted Rivets | Decorative Panels, External Trim | Aesthetic, enhances overall appearance |

| Large Flange Rivets | Thin Metals, Door Hinges | Increases clamping area, prevents soft material damage |

| Grooved Rivets | Plastic Parts, Door Frames | Extra grip, prevents slippage |

| Multi-Grip Rivets | Frame, Base | Adapts to various material thicknesses, high flexibility |

How to Choose the Right Rivets for Mailbox?

There are a number of factors to consider when selecting the best rivets for a mailbox project. This ensures that the rivets will not only meet the mechanical strength requirements, but also maintain good durability in the environment. Below are a few important factors to look at when selecting rivets for your mailbox project:

1. Material Selection

- Aluminum Rivets: Aluminum rivets are commonly used in aluminum mail boxes because they are lightweight and easy to handle.

- Stainless Steel Rivets: Used where corrosion resistance and strength are required.

- Galvanized Steel Rivets: For use in metal mailboxes or mailbox projects exposed to inclement weather.

- Copper rivets: for use in specialty applications or mailboxes with aesthetic requirements.

2. Environmental Conditions

- Outdoor use: choose rivets with high corrosion resistance, such as stainless steel or galvanized rivets. This way mailbox can cope well with the effects of elements such as wind, rain, moisture and UV rays.

- Indoor use: If it is placed indoors, you can choose lower cost aluminum rivets.

3. Aesthetic Requirements

For mailboxes that require a high level of appearance, it is recommended to use rivets with a surface finish (e.g., painted rivets or decorative rivets). These rivets will harmonize with the design of the mailbox and enhance the overall appearance.

Do You Have Any Questions?

Let Us Solve Your Problem

Custom Rivets Solutions for Mailbox Project

For thin sheet products, rivets are a solution installation solution. It provides a stable connection and is inexpensive. If you would like to purchase a large quantity of mailbox rivets for your project, please contact us.

Get samples of rivets for testing today.