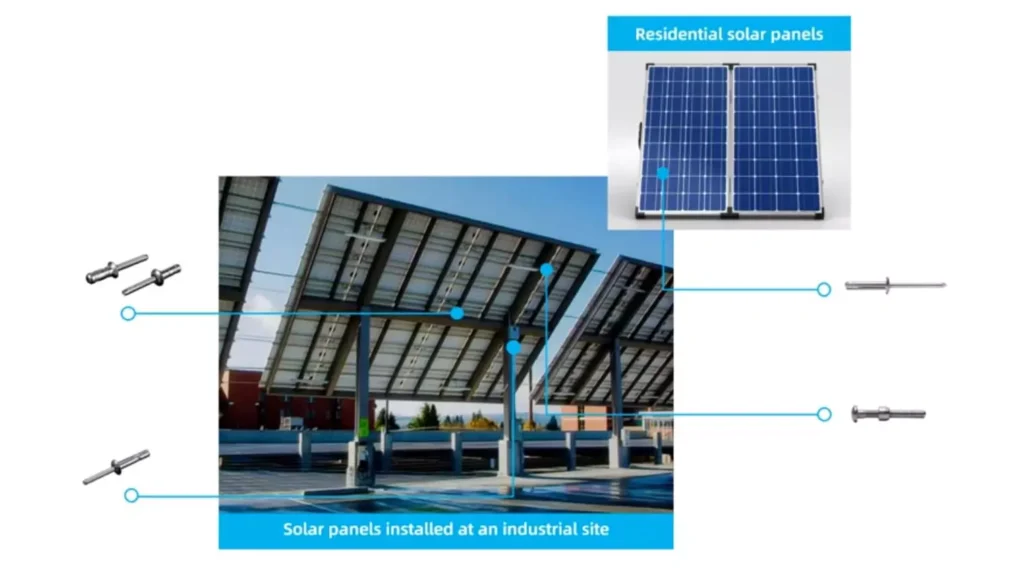

Solar Panel Fastening System Solutions

—— Rivet Solutions for Solar Panel Assembly and Mounting

As solar energy systems scale globally, efficient and reliable mechanical fastening solutions are essential. Rivmate offers a full range of rivet products optimized for solar panel module assembly and mounting structures.

Applications of Rivets on Solar Panel

Rivets are widely used in solar panels. The following are common application scenarios of rivets on solar panels:

- Panel bezel connection (aluminum profile fixing)

- Junction box bracket fixing

- Panel-to-support connections (especially in BIPV or customized module configurations)

- Small inverter support or cover part fixing

- Cable duct and metal accessory mounting

| Application Area | Recommended Rivet Type | Recommended Material | Features & Application Notes |

|---|---|---|---|

| Aluminum frame joints and reinforcement | Open-end blind rivets (low-expansion) | Aluminum / Stainless Steel | Lightweight, conductive, avoids galvanic corrosion in aluminum profiles |

| Junction box bracket mounting | Small flange / Large flange rivets | Stainless Steel / Aluminum | Supports automated assembly, protects plastic from cracking or deformation |

| Module-to-structure fastening | Structural blind rivets / Closed-end rivets | Zinc-plated Steel / Stainless Steel | High shear & tensile strength, anti-vibration, suitable for outdoor loading |

| Mounting accessories (e.g., cable trays) | Multi-grip or large flange rivets | Zinc-plated Steel / Stainless Steel | Tolerates panel thickness variation, distributes load, prevents slippage |

| Inverter cover plates or metal fixtures | Sealed blind rivets / Closed-end small head | Stainless Steel / Aluminum | Ensures waterproof sealing, corrosion resistance for outdoor exposure |

| BIPV louvers or rail-to-structure joints | Deep-grip blind rivets / Custom rivets | Stainless Steel / Aluminum | Ideal for thin/irregular parts, precise positioning for building-integrated PV |

Why Choose Us for Solar Panel Applications?

Rivmate’s rivets are engineered to meet the mechanical and environmental challenges of modern solar panel installations.

Built for harsh outdoor use – heat, moisture, UV, and corrosion resistant

- Selection of high anti-corrosion materials (stainless steel 304, aluminum, galvanized steel), to meet the requirements of more than 25 years of design life.

- Dacromet, electro-galvanized, black zinc and other surface treatments are available to enhance salt spray corrosion resistance.

- Provide closed type and anti-loosening type rivets to prevent rainwater intrusion and structure loosening.

One-stop supply of solar rivets – standard or customized

As a professional rivet manufacturer, Rivmate has rich experience in solar panel application. And we can provide solar panel fasteners one-stop purchasing service to solve all your purchasing needs at once.

- Covers a full range of blind rivet sizes from ⌀3.2mm to ⌀12.7mm

- Support special grip range, head shape and material customization.

- OEM/ODM service, provide packaging and labeling with customer’s logo.

From prototype to bulk – we deliver what you need, when you need it

- Factory stock, the fastest delivery of mainstream specifications is 7 days, supporting monthly rolling order system.

- Familiar with the international project documentation process, provide COC/COA/Certificate of Origin/Invoices and other export information.

- A team of engineers can participate in the early stages of component structural design to optimize connection design and process adaptation.

Design specialized riveting solutions for your PV panel structures

- Designed for structural strength and thermal expansion of aluminum bezels, bracket systems, and rail accessories

- Supports ISO, TÜV, RoHS, REACH and other certifications to meet global EPC project compliance requirements.

- Low head height, impermeable, small cap or large cap flanges available to meet different application scenarios

Solar Panel Fastening System

Rivmate has a wide range of blind rivets for solar panel applications.

Structural features:

- Closed end blind rivets, locking core locked in the rivet body, waterproof, anti-vibration

- Uniform expansion, suitable for high shear strength demand occasions

- Blind mounting holes, suitable for one-sided operation

Application on Solar Panel:

- Solar racking main beams and diagonal bracing connection: to provide a high strength, wind load resistant fixing point

- PV inverter metal housing, junction box support plate fixing: closed structure to prevent water vapor ingress

- In double-glazed modules or hermetically sealed frame construction: maintains airtightness and structural rigidity

Advantage:

- Waterproof, anti-loosening, suitable for harsh outdoor working conditions

- Visual inspection of the locking cylinder position after installation to ensure consistent quality

Structural features:

- Headless top, with locking ring mechanical locking structure

- Extremely high shear and tensile strength, no risk of loosening under vibration conditions

- Installation with special tools (e.g. Huck equipment)

Application on Solar Panel:

- Connection of structural steel components in large ground power plants: e.g. flange connection of rails to ground piles, H-beam splices

- Alternative to welding or bolting in high wind pressure areas or high altitude projects

- Structural reinforcement in projects with seismic requirements

Advantage:

- Permanent structural connection with high fatigue life

- Anti-theft and anti-demolition, suitable for high security scenarios

Structural features:

- Mechanical locking mandrel, mandrel does not fall off

- Uniform expansion of the broach structure, suitable for multi-layer or soft materials

- Can be used in a wide range of aperture tolerances

Application on Solar Panel:

- Aluminum bezel to support: Provides a solid connection on thin-walled aluminum alloys.

- Junction box bracket fixing: efficiently absorbs thermal expansion and contraction of the backsheet

- Positioning of hidden structural elements within the panel

Advantage:

- Avoids mandrel loosening and dislodging, suitable for sealing and vibration-resistant parts

- High tolerance of installation tolerances, suitable for fast assembly lines

Structural features:

- Multi-flap expansion structure with “bulb-shaped” back locking zone

- Ideal for joining thin, brittle or non-metallic materials.

- Large flange head distributes clamping force and prevents material cracking

Application on Solar Panel:

- Fixing of raceways, cable guide rails, crimping strips: mounting of accessories on aluminum or composite structures

- Positioning of plastic or fiberglass brackets on module frames: avoiding cracks caused by hard connections

- BIPV (Building Integrated Photovoltaic) façade module attachment points

Advantage:

- Low mounting stress to prevent damage to lightweight materials

- Easy blind mounting operation for quick on-site assembly

FAQs of Rivmate Solar Panel Fastening System Solutions

1. Will rivets used in PV module installation rust?

Rivmate offers rivets made of highly corrosion resistant materials (stainless steel, aluminum alloy, galvanized steel) with optional surface treatments such as electro-galvanized and Dacromet for excellent corrosion resistance. Aluminum and stainless steel rivets are especially suited for long-term outdoor exposure and are designed to meet the 25-year life expectancy of PV systems.

2. Can rivets be used in place of bolts for solar racking connections?

For structural connections (e.g. brace main beams, diagonal brace connections), the use of structural rivets (e.g. Monobolt, Lockbolt) can completely replace traditional bolted connections. Rivets offer the advantages of resistance to loosening, vibration, and high strength, while simplifying the assembly process and reducing maintenance requirements.

3. What types of solar module bezels do Rivmate's rivets fit into?

We offer a wide range of Blind Rivets, Triple Flap Rivets and Closed End Rivets to fit common aluminum bezels (25mm/30mm/35mm/40mm). We also support customized rivet solutions for non-standard frame configurations to ensure that grip range, expansion strength and edge stability are in accordance with component factory standards.

4. Do I need special tools to install solar panel rivets?

Blind rivets used in solar panels are generally of high strength. Therefore, electric or pneumatic rivet guns (to suit the core size) are required; structural rivets (e.g. Lockbolt) are recommended to be used with special hydraulic or pneumatic tools.Rivmate can advise on the selection of tooling or provide a rental service for bulk purchases.

5. Are rivets suitable for BIPV or glass-based modules?

Rivets are of course suitable for solar panels. there are many types of blind rivets available and there is a suitable riveting solution for any laminate application. rivets on BIPVs or glass-based assemblies must be constructed with a low expansion stress, large area force distribution structure such as Bulb-Tite, Tri-Fold, etc. to avoid point load concentrations that can cause cracking in the glass or composite panel structure. These rivets are effective in avoiding point load concentrations that can cause cracking of the glass or composite panel structure.Rivmate offers a customized line of riveting products specifically designed for BIPV.