Speed Rivets

Your single source for wholesale speed rivets, with factory-direct manufacturing and stable supply.

What Are Speed Rivets & Why They Improve Assembly Efficiency

Speed Rivets (also known as Fast Rivets) are a type of fastener designed primarily for rapid installation and simplified assembly processes, targeting industrial applications with high demands for assembly efficiency and cost control.

The term “Speed” manifests in three key aspects. First, rapid insertion. Speed Rivets feature a simple structural design that allows smooth insertion, reducing reliance on precise hole positioning and manual labor. Second, rapid locking. During installation, the rivet rapidly expands or locks into place without complex adjustments. Third, reduced process steps. Certain Speed Rivets can be installed manually or with simple tools, lowering the need for specialized equipment and training.

How Speed Rivets Work in Fast Industrial Assembly

The functionality of Speed Rivets revolves around the principle of “Quick Insertion + Quick Locking,” designed to minimize assembly steps and reduce installation time. During installation, the rivet is directly inserted into a pre-drilled hole and then expands or locks into place through its own mechanism or with minimal external force, achieving a secure fastening. This process avoids complex actions like core extraction and breaking, making operation highly intuitive.

The need for pre-drilling depends on the specific Speed Rivet type. Metal Speed Rivets typically require pre-drilled holes to ensure dimensional accuracy and assembly consistency. Conversely, certain plastic or push-in Speed Rivets can be directly pressed into molded holes or soft materials, further reducing upfront preparation steps.

WHY USE IT

Speed Rivets Product Features & Advantages

Fast Installation

Speed Rivets feature fewer installation steps and rapid insertion/locking, significantly reducing assembly cycle times and boosting overall production efficiency.

Simple Operation

Intuitive operation requires minimal adjustments for most models, reducing reliance on operator experience and skill.

Reduced Labor Cost

Short installation times and minimal training requirements effectively lower labor expenses, making them particularly suitable for high-volume assembly scenarios.

High Assembly Consistency

Simple structural design ensures stable installation results, helping maintain consistent assembly quality during mass production.

Minimal Tooling Requirement

Most Speed Rivets can be installed manually or with basic tools, eliminating the need for specialized riveting equipment and reducing capital investment.

Suitable for Thin and Light Materials

Ideal for connecting thin sheets, lightweight metals, or plastic components, achieving secure fastening without adding structural burden.

Cost-Effective Fastening Solution

Compared to structural fasteners, Speed Rivets offer superior overall cost efficiency while meeting fundamental strength requirements.

Wide Application Flexibility

Versatile for automotive interiors, home appliances, electronic devices, and light industrial assembly, demonstrating strong adaptability.

Order Rivmate Speed Rivets to Provide Productivity on Your Projects

As one of the top speed rivets supplier in China. We have the ability to provide you with high quality speed rivets.Whether it’s aluminum speed rivet, carbon steel speed rivet, round head speed rivet and countersunk head speed rivet, we can provide it. Choose your ideal type of speed rivets now!

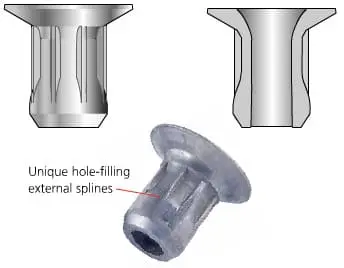

BRV Series Speed Rivet

BRV Speed Rivets are fasteners with a unique spherical end. Suitable for use with most materials including steel, stainless steel, aluminum and plastics, BRV Speed Rivets can be supplied to provide high joint clamping forces.

CBT Series Speed Rivets

CBT Speed Rivets provide a consistent joint and are optimal for soft or brittle materials.CBT Speed rivets have a slightly lower clamping force than BRV Speed Rivets.

Custom Speed Rivets

We can customize speed rivets in a variety of head styles, materials, and finishes to meet your project needs. contact us for speed rivets to match your project.

Custom Speed Fastening Rivets to Complete Your Business

Custom Head Style of Speed Rivets

Rivmate can provide you with both Dome heads and Countersunk heads. Of course, We can customise a special head shape for your project.

Custom Materials of Speed Rivets

- Carbon Steel

- Aluminum

- Stainless Steel

- Brass

Custom Diameter of Peel Rivets

- 2.4mm(3/32″)

- 3.2mm(1/8″)

- 4.0mm(5/32″)

- 4.8mm(3/16″)

- 6.0mm(15/64″)

- 6.4mm(1/4″)

comparison

Difference Between BRV Speed Rivets and CBT Speed Rivets

| BRV Speed Rivets | CBT Speed Rivets | |

| Clamping Force | BRV Speed Rivets provide high clamping forces. | CBT Speed Rivets provide a consistent clamping force that reduces potential damage to soft or brittle materials. |

| Carrying Capacity | The bulbous tail and large head shape provide a large carrying area for soft materials. | The contact area of CBT Speed rivets is not as large as that of BRV Speed rivets, but the same can be passed to meet the needs of the application. |

| Ease of Access to the Hole | Tapered tail allows easy access to the hole. | Internal tapered hole design for soft or brittle materials. |

| Common Applications | Automotive, electronic components, sheet metal, electrical engineering, household appliances, furniture and general light manufacturing. | Automotive, electronic components, sheet metal, electrical engineering, injection molded parts, switchgear, household appliances and light manufacturing. |

comparison

Comparison Table|Speed Rivets vs Other Fasteners

| Comparison Aspect | Speed Rivets | Standard Blind Rivets | Screws | Push-in Fasteners |

|---|---|---|---|---|

| Installation Speed | Very fast | Medium | Slow | Very fast |

| Pre-Drilling Required | Usually yes | Yes | Yes | Sometimes no |

| Installation Tools | Hand or simple tools | Rivet gun required | Screwdriver / torque tool | Hand pressure |

| Assembly Consistency | High | Medium | Depends on torque | Medium |

| Load Capacity | Light to medium | Medium to high | Medium to high | Light |

| Rework / Disassembly | Limited | Difficult | Easy | Easy |

| Automation Suitability | High | Medium | Medium | High |

| Typical Applications | Light industrial assembly | Structural sheet metal | Maintenance assemblies | Plastic panels |

Speed Rivets vs Standard Blind Rivets

Speed Rivets emphasize faster installation and easier operation, making them ideal for efficiency-driven assembly scenarios. Standard Blind Rivets offer higher strength but require riveting tools, resulting in slower installation cycles.

Speed Rivets vs Screws

Speed Rivets eliminate torque control requirements and reduce assembly steps, minimizing installation errors. Screws offer the advantage of being removable, but their installation is time-consuming and incurs higher labor costs.

Speed Rivets vs Push-in Fasteners

Speed Rivets outperform standard Push-in Fasteners in stability and consistency, particularly for metal-to-metal connections. Push-in Fasteners are better suited for plastic components or extremely light-load applications.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

Suitable Materials & Applications

Suitable Materials and Applications for Speed Rivets

Thin Sheet Metal

Speed Rivets are ideal for thin sheet metal connections, enabling rapid fastening without adding complex processes. Common applications include lightweight steel and aluminum sheet assembly, particularly suited for scenarios demanding high assembly efficiency.

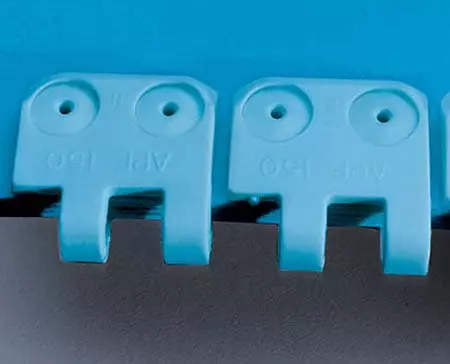

Plastic Components

In plastic part assembly, Speed Rivets provide stable fixation through quick insertion and locking. Compared to screws, plastic parts are less prone to cracking from overtightening, ensuring better assembly consistency.

Light-Duty Composite Materials

For light-duty composite materials, Speed Rivets deliver sufficient holding force while avoiding complex machining processes. This application is best suited for non-structural or decorative components.

Not Suitable Applications

Speed Rivets are not suitable for high-load structural connections, thick sheet metal, or high-vibration environments. In these scenarios, where higher connection strength and durability are required, structural blind rivets or other high-strength fastening solutions should be selected.

APPLICATIONS

Typical Applications of Speed Rivets

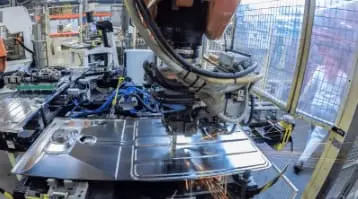

Automotive Trim & Interior Parts

Speed Rivets are commonly used for securing automotive interior trim and decorative components. They enable rapid installation, meeting the demands of high-volume production cycles. Ideal for non-structural connections.

Electronics Enclosures

In electronic device housings, Speed Rivets enable rapid assembly. They reduce screw counts, boost production efficiency, and maintain a clean appearance.

Household Appliances

Ideal for connecting appliance housings and internal lightweight components. Simple operation helps reduce assembly time and labor costs.

Furniture & Fixtures

Speed Rivets enable lightweight connections in furniture and fixtures. Installation is intuitive. Suitable for batch assembly scenarios.

Light Industrial Assembly

In light industrial assembly, Speed Rivets provide stable fixation. No complex tools required. Enhances overall assembly efficiency.

Plastic and Mixed-Material Components

Suitable for light-duty connections in plastic parts or metal-plastic assemblies. Minimal material damage. Ensures consistent assembly results.

Buy Speed Fastening Rivets

Why Choose to Buy Speed Rivets From Rivmate?

If you want to buy a lot of speed rivets, then you can come to contact us directly!

Rivmate is the top pop rivet manufacturer in China. We are committed to providing our customers with the best quality service and the most perfect products. Our professional and fast customer service can meet the various requirements of your project and provide you with the most professional rivet solutions.

Trust us, you will be amazed by our customer service! You can get unparalleled riveting advice and other services.

Where to Buy Speed Rivets?

Typically, Speed rivets are used in fully automated plants of industrial manufacturers. They use speed rivets in conjunction with automatic mounting machines. I am sure that you are either a buyer or an engineer of a manufacturer reading this article. Then you have come to the right place.Rivmate can provide a large number of high quality speed rivets for your project.

As speed rivets manufacturer and supplier, you can provide us with your requirements. Including customized sizes, types, finishes, materials, head styles and more.

Order Speed Rivets from Rivmate Now!

FAQs – Speed Rivets

Q1. Are Speed Rivets suitable for fast assembly?

Yes. Speed Rivets are designed for rapid insertion and simplified operation, requiring fewer installation steps and typically no complex tools. This significantly reduces assembly time, making them particularly suitable for mass production and efficiency-driven assembly scenarios.

Q2. What is the load capacity of Speed Rivets?

Speed Rivets are generally suitable for light to medium load applications. While their load capacity is lower than structural blind rivets or locking rivets, they meet basic strength and stability requirements for non-structural connections.

Q3. Can Speed Rivets replace screws?

Speed Rivets can substitute screws in applications where disassembly is not required. Compared to screws, Speed Rivets eliminate torque control needs, offer faster assembly speeds, and provide greater assembly consistency. However, screws are more suitable for applications requiring frequent maintenance or disassembly.

Q4. Are Speed Rivets suitable for plastic components?

Yes. Speed Rivets reduce clamping stress during plastic assembly, lowering cracking risks. They are particularly suitable for securing thin-walled plastics or cosmetic parts.

Q5. Do Speed Rivets require special installation tools?

Most Speed Rivets can be installed manually or with simple tools, eliminating reliance on specialized riveting equipment. This helps reduce equipment investment and operator training costs.