Structural Rivets

Structural rivets are fasteners designed to create high-strength connections.

In modern manufacturing, high-strength connection solutions are important to ensure product quality and performance. Structural rivets are widely used in various industries as a fastener with high strength joining capabilities.

Structural rivets are capable of creating high strength connections. Made from strong and durable materials, they are able to withstand critical stresses and vibrations. RIVMATE is a leading service provider of customized structural rivets solutions in the manufacturing and construction industries worldwide.

In this article, we will introduce the characteristics of structural rivets, how to use them and how to choose the right structural woolen empire. Helping you to understand how to use structural rivets to create high strength joining solutions.

What are the types of structural rivets

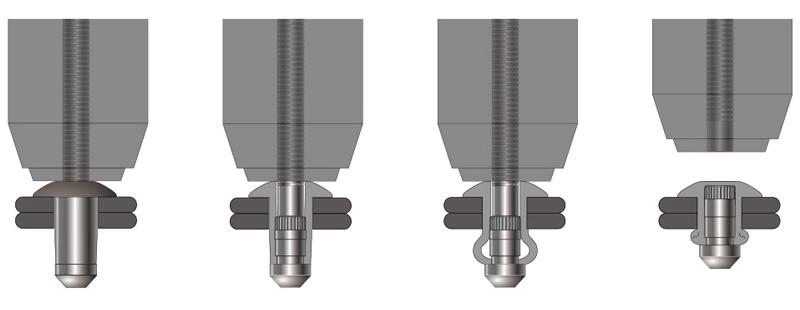

Rivmate Boom-Lock Blind Rivets

Boom-Lock Blind Rivet is a high strength structural blind rivet, also known as Bom rivet.

Boom-Lock Blind Rivet is an ideal choice for high load requirements and single-sided installations.

During installation the tool stretches the top bar and the coworker squeezes the brim to create plastic deformation, resulting in the characteristic ring-groove locking effect. The deformed area is tightened to achieve a reliable and tight connection.

Boom-Lock Blind Rivet solves the problem of common blind rivets loosening under vibration. Meanwhile, it has higher precision, higher productivity and excellent anti-vibration performance.

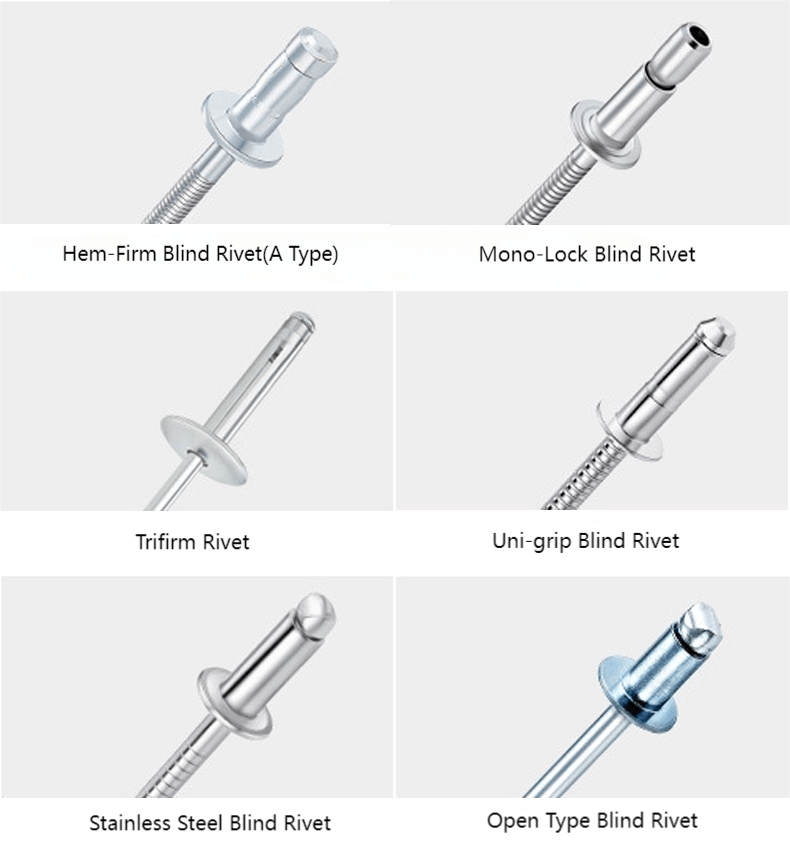

Bulbtight Trifirm Rivet

Bulbtight Trifirm Rivet is a special structural blind rivet. It is uniquely designed to be waterproof and corrosion resistant. Rubber gaskets are added to prevent water ingress during use. The all-aluminum construction of the rivet provides corrosion resistance.

Riveted to form a lantern shape during installation and use, creating three large folding feet for additional riveting area.

Now-Lock/Mono-Lock Blind Rivet

Now-Lock/Mono-Lock Blind Rivets are one of the very important products in structural blind rivets. It has double locking function and closure. After riveting the nail core is locked in the rivet body to form a high tensile and shear strength.

Draw rivets are metal connectors with a unique structure and high riveting strength. Belong to is a new type of fastener. Draw core rivets rivet core is pulled into the rivet body, under the action of a special rivet gun, the core of the nail broken nail will be flanged into the groove of the rivet body, the formation of a “mechanical external lock”, locking the nail core.

Hem-Firm Blind Rivet

Hem-Firm Blind rivets are structural rivets with superior shear and tensile strengths, high vibration resistance and large blind end bearing areas that are not prone to deformation. It is suitable for riveting areas with high riveting strength requirements and requirements for sealing performance.

The spline locking core structure of Hem-Firm Blind Rivets is designed to provide a strong vibration-resistant connection that prevents rattling in time.

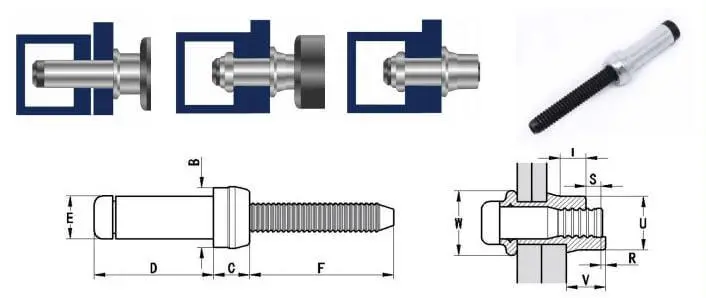

Rivlok & Rivbulb Double-locking System

Double-locking blind rivets are compact, high-strength connectors. It is used to create stable connections between materials. They are corrosion resistant and durable.

The principle of type riveting is used for installation. They are unfolded by applying pressure to form a secure connection. This unique design provides reliable tensile and shear strength. And it is able to remain stable under conditions of vibration and load.

How do structural rivets work?

There are some differences between structural rivets and standard blind rivets when it comes to work. This is because when riveting a structural rivet, the inside of the structural rivet locks a portion of the mandrel inside the rivet body, which creates another type of lock. This special structural design helps to increase the joint strength of the rivet.

Based on the principle of force transmission and expansion. Structural rivets use this principle to clamp materials to be joined together to form a strong connection. This type of connection provides high strength and stability and is used in a variety of applications.

- Increased shear strength

- High strength connections

- Good resistance to earthquakes

- It’s hard to get loose.

- Waterproof and dustproof

Advantages of Structural Rivets

Compared to ordinary blind rivets. Structural rivets can provide super high strength. Structural rivets have many advantages.

- Unilateral mounting. More usage scenarios

- Creates reliable, high-strength connections. Stable under vibration, shock and load conditions.

- The structural design is flexible. A variety of customized structures can be paired to suit most applications.

- Structural rivets can be used in harsh environments for long periods of time. Good durability and corrosion resistance.

- Quick installation. Faster than traditional bolts and nuts. Can complete the riveting process in a very short time.

- Easy to inspect and maintain

- The structural rivets are very small. It can save a lot of space for connections and can be advantageous in limited space applications.

- Structural rivet connections are generally tight. It can provide a good sealing performance. Can have waterproof performance to a certain extent.

How to install Structural Rivets?

The installation of blind rivets is all relatively similar. All require specialized riveting tools. For example, some structural rivets require the Hemlock Rivet Tool, Monolock Rivet Tool, Lockbolt Tool for successful installation.Ordinary rivet guns do not have the ability to install these special rivets.

Except the riveting tool is slightly different. The process of riveting structural rivets is not much different from regular rivets.

- Need to pre-drill an appropriately sized hole

- Load the end of the rivet into the rivet gun

- Activate the riveting tool to install the rivets to the surface of the material.

- As soon as the rivet breaks. This means the end of the riveting process.

How to Remove Structural Rivets?

Removal of structural rivets is essentially the same as standard blind rivets.

You can use everything from drills, screwdrivers, and other hard accessories.

- Punch a hole in the center of the rivet

- Choose a suitable drill bit and apply some lubricant to the bit.

- Use a drill bit to drill through the rivet until it is completely through the hole.

Which is the best tool for structural rivets?

There is a saying that rings true. There is no such thing as the best tool, only the most appropriate tool.Therefore, there is no best riveting tool, only the most suitable riveting tool.

So how do you choose the right rivet gun? It all depends on your project and your requirements for efficiency.I’ll tell you about the main types of rivet guns available in the world today and their advantages and disadvantages.At Rivmate.We offer what we believe to be the best rivet guns available. The vast majority of personal and industrial requirements can be met. Our website provides detailed information for you to view. For further discussion, please contact us.

There are three main types of structural riveting tools:

- Electric Rivet Gun

- Pneumatic Rivet Gun

- Hand Rivet Gun

The Rivmate tool is suitable for installing all types of structural rivets.

Electric Rivet Gun

The power source of electric rivet gun is lithium battery, the power source is more convenient than gas source, but less suitable for industrial mass production. Electric rivet gun is more suitable for home or small batch production of outdoor work, easy to use and labor-saving.

Pneumatic Rivet Gun

The power source of pneumatic rivet gun is air pressure, so the use of pneumatic rivet gun is required to be equipped with an air source. Pneumatic rivet guns are very efficient and the tool can provide a high pulling force. It is easy to maintain and is suitable for industrial batch work.

Hand Rivet Gun

The power source of the hand rivet gun is the operator’s two hands, so the operator’s strength will be directly related to receive the efficiency of the work of the rivet gun. But in the case of heavy workload operators will feel very tired.

The advantage of manual rivet guns is that there are basically no requirements on the application scenarios, and they are more suitable for use in small batch production operations.

How to Choose The Right Structural Rivets?

There are many factors to consider when trying to choose the right structural rivets for your project. For example, material, size, riveting range, head style and riveting strength. Here you will learn how to pick the right structural rivet for your project from a number of factors.

Structural Rivet Manufacturing Materials

Structural rivets can be made from a variety of materials. But different application scenarios require different materials. So it is important to choose the right manufacturing material according to the actual application of your project.

When choosing materials for manufacturing, you need to make sure that the rivets are compatible with the materials to be joined to avoid galvanic corrosion. Typically, we do not choose both aluminum and stainless steel.

Common material pairings include the following:

- All Carbon Steel

- All 304 Series Stainless Steel

- Carbon Steel/Aluminum

- 304 Stainless Steel/Aluminum

- All Aluminum

- Carbon Steel SWCH45K/Carbon Steel 10B21

- 304/302 Stainless Steel

- All Steel

Rivet Size

The size of the rivets is very important. If the rivet size is not chosen correctly, then the installation will fail as a direct result. You should refer to the rivet size before drilling the holes. It is important to match the size of the hole with the size of the rivet in order to avoid the problem of installation failure.

Riveting range

Rivet range represents the width that a structural rivet can connect. For example, if you need to rivet two materials that are 3mm wide, you need to purchase a structural rivet with a rivet range greater than 3mm. However, the smallest rivet range should not be selected. Best practice suggests that the middle grip range of the rivet should be selected. This helps in achieving the correct shear and tensile strength. It is important to note here that the riveting range does not represent the length of the structural rivet.

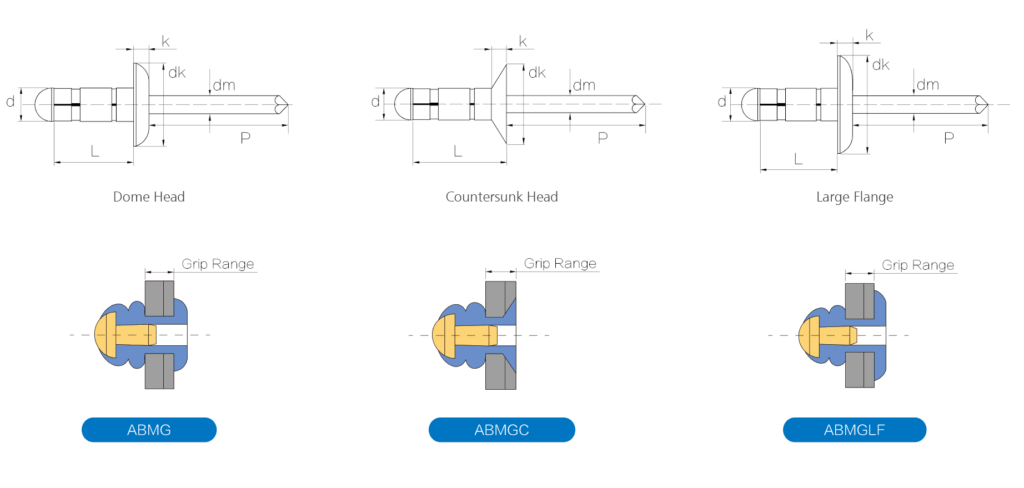

Rivet head shape

Rivet head types are used to help achieve a reliable appearance on a material. the Dome Head is firmly secured to the top of the material. the Large Flange is a shallower, wider head profile that is suitable for thin or soft materials such as thin steel sheets. the Countersunk Head allows the head of the rivet to be buried directly into the material, resulting in a flat surface. the Rivet Head can also be used as a base for the rivet.

Customized Structural Rivets for Your Project

Not sure how to choose the right structural rivets? Don’t worry, contact us. Tell us your needs, we will give you the most professional structural rivets solution. Perfectly solve all your questions about structural rivets.

Frequently Asked Questions about Structural Rivets

Can I get colored structural rivets?

Sure. We offer you a wide range of technologies for the treatment of various surfaces. Different colors can be customized for your rivets.

Are structural rivets superior to Huck bolts?

Both connectors provide high connection strength. Both ensure the stability of the connection.When installing Huck bolts, you need to be able to access both sides of the connected product. Structural rivets require access to only one side for direct installation.

Do you sell rivets worldwide?

Yes. We sell worldwide. We have exported our structural rivets to more than fifty countries in the world and have established long-term and stable cooperation with our customers. The quality of our rivets has received favorable comments from our customers.

We’ll provide you with one-on-one service. All countries of the world are our partners.

Please contact us!

What are the main application scenarios for structural rivets?

There are many types of structural rivets, so there are many application scenarios for them.

- automobile manufacturing

- rail link

- Solar panel bracket connection

- aerospace

- Subway car manufacturing connections

- High-speed train carriages