Table of Contents

Open end blind rivets are one of the most commonly used types of rivets. Business owners need to know the basic information about open end blind rivets before making a purchase. This comprehensive guide will give you a good help.

Table of Contents

What Are Open End Blind Rivets?

Open End Blind Rivets consist of two parts, a hollow cylindrical head and a high strength nail. It was originally designed to accomplish quick installations without the need for closure. Because open end blind rivets are so widely applicable, they are now one of the most commonly used blind rivets. They are used in a wide variety of industrial applications such as aerospace, automotive manufacturing, construction and electronic equipment manufacturing.

There are many different types of open end blind rivets to suit a variety of different applications. These include differences in head: dome head, countersunk head and large flange head. differences in material: aluminum, carbon steel and stainless steel.

History of Open End Blind Rivets

To solve the problem of difficulty in making quick dark turns in certain areas of an airplane, the pultruded rivet was invented in the 1950s. Most early blind rivets were designed with closed ends to prevent water and air infiltration. However, over time, open end blind rivets were designed to fulfill applications that did not require a complete seal. And open end blind rivets are cheaper to manufacture and have a wider range of applications.

With the development of material science, the material of open end blind rivets also expanded from the initial steel and aluminum to stainless steel, copper and other materials.

How do Open End Blind Rivets Work?

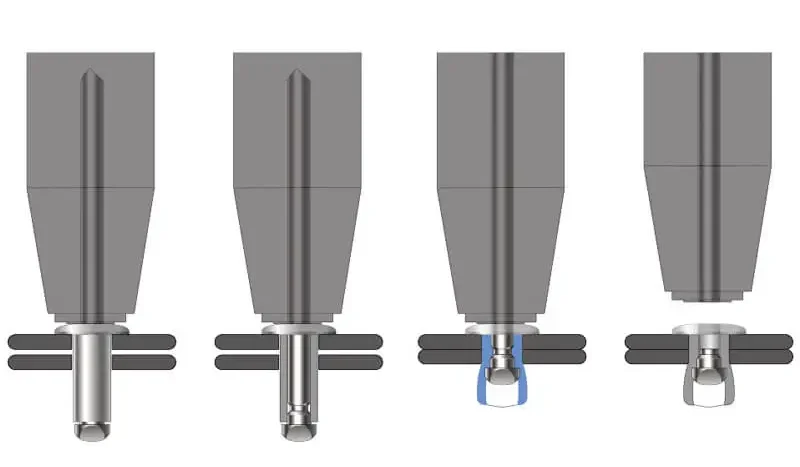

The principle of open end blind rivets is to form a stable connection through the extrusion and deformation of the rivet head.

When installing open end blind rivets using a specialized rivet gun, the rivet gun locks the open end blind rivet’s rivet nail and then applies a set amount of pressure. This pulls on the rivet body and deforms it so that the rivet head and rivet body can form a stable connection on both sides of the material.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

How to Install Open End Blind Rivets?

Advantages of Open End Blind Rivets

- Open end blind rivet is simpler in construction and do not require additional manufacturing processes. So open end blind rivets are typically less expensive to manufacture than other types of blind rivets. This gives them a significant advantage in cost-sensitive applications.

- Because the open end blind rivet has a simple design and no additional closure components, it is typically lighter than closed end rivets. Ideal for applications that require weight savings, such as certain automotive and electronic equipment.

- Open end blind rivet allows the open portion of the rivet to be exposed after installation, making it easy to visually check for proper installation. This is especially important in applications where quality and safety need to be assured.

- In some applications, the open design can allow air or liquids to pass through, preventing problems with water buildup or poor ventilation.

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

Disadvantages of Open End Blind Rivets

- Due to the open-end design, blind rivets with openings do not provide a complete seal.

- Open end blind rivet has lower tensile and shear strengths than closed end rivets. They are not suitable for connections with extremely high strength requirements.

- The open-end construction exposes the interior portion, making it more susceptible to corrosion, especially in wet or corrosive environments.

- In some cases, the open-end design may result in the exposure of mandrel remnants, increasing the potential risk of dislodgement, which could lead to safety issues or damage to surrounding equipment

Types of Open End Blind Rivets

The type of open end blind rivet is determined by its head type and material. So how many types and material combinations of open end blind rivets are there? Let’s look at them together below.

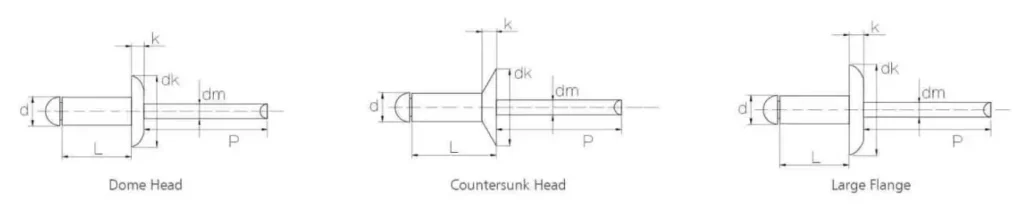

Types of Head

In order to accommodate a variety of different application scenarios, open end blind rivets have a total of three different types of heads.

- Dome Head

- Countersunk Head

- Large Flange Head

Types of Rivet & Mandrel Materials

- Aluminum Rivet/Carbon Steel Mandrel

- Aluminum Rivet/Aluminum Mandrel

- Aluminum Rivet/Stainless Steel Mandrel

- Carbon Steel Rivet/Carbon Steel Mandrel

- Stainless Steel Rivet/Stainless Steel Mandrel

Contact Our Engineers Today

We provide you with high quality rivets, including customized services.

What is the Difference Between Open End and Closed End Blind Rivets?

| Aspect | Open End Blind Rivets | Closed End Blind Rivets |

| Design Structure | Rivet body with an open end, visible mandrel | Rivet body with a closed end, fully enclosed mandrel |

| Sealing Performance | Does not provide sealing, cannot prevent liquid or gas leakage | Provides sealing, effectively prevents liquid and gas penetration |

| Strength | Generally lower, especially in tensile strength | Typically higher, offering greater tensile and shear strength |

| Corrosion Resistance | More exposure to elements, potentially more prone to corrosion | Closed design offers better corrosion protection |

| Suitable Environment | Suitable for non-sealed applications, such as standard metal and plastic fastening | Suitable for environments requiring water or gas sealing, such as potential liquid exposure scenarios |

| Mandrel Retention | Mandrel may be exposed, potential retention issues | Fully enclosed mandrel, eliminating retention issues and enhancing safety |

| Aesthetic Appearance | Open end may be less aesthetically pleasing | Closed design provides a clean appearance, suitable for high-finish applications |

| Cost | Generally lower, suitable for cost-sensitive applications | Typically higher, suitable for applications with sealing and strength requirements |

| Weight | Lighter, suitable for weight-sensitive applications | Heavier, but provides better strength and sealing |

If you want to know more about open end blind rivets and closed end blind rivets and the differences between them, read this article “Closed End vs Open End Rivet“.

Frequently Asked Questions

Are Pop Rivets Stronger Than Screws?

Do you know who is stronger, rivets or screws?

Pop Rivets are often superior to Screws in terms of strength and stability, especially in applications where permanent, vibration-resistant and high-strength connections are required. Examples include aerospace, automotive and construction. However, once installed, Pop Rivets are often difficult to dismantle and are therefore not suitable for applications where frequent maintenance or dismantling is required.

Screws are superior in terms of flexibility and maintainability. They are easy to install and dismantle and are suitable for applications where components need to be regularly inspected, repaired or replaced, such as furniture assembly and electronic equipment.

What is the Reason for Using Open End Blind Rivets?

Although open end blind rivets came after closed end blind rivets, open end blind rivets continue to be an ideal choice for many industrial and commercial applications. In applications where sealing of the structure is not required, open end blind rivets are widely used due to their ease of one-side operation, quick installation efficiency, strength and reliability, cost-effectiveness, suitability for a wide range of materials, lack of need for special post-treatment, venting and draining capabilities, and ease of visual inspection.

Do Open Rivets Leak?

Of course, as you can tell from the name open end blind rivets, they are not waterproof.Open end blind rivets have an open bottom of the rivet body, which does not create a complete seal on the bottom after installation. Gases, liquids can penetrate through the opening.

So if your project requires sealing, then we don’t recommend you to use open end blind rivets, you should use closed end blind rivets with better sealing performance.So do you want to know which rivets are sealed? Read my article “Do Pop Rivets Leak“.

How Should I Buy Open End Blind Rivets?

When you want to buy open end blind rivets in large quantities, there may be a lot to consider. However, from my experience, you only need to consider three things:

- budget

- quality

- reliability of the manufacturer

Of course, it’s not that the other factors aren’t important, it’s just that these three are the ones that really make or break a deal.

First, let’s talk about budget. Budget can directly determine the quality of open end blind rivets. As we all know, the price of good quality rivets is relatively high, and the price of poor quality rivets is very low. You should be clear about the requirements of your project, is it a requirement for quality, or just cheap price will do.

The next thing is the quality. Every business owner wants to buy the best quality rivets at the lowest price. But this is obviously not possible. When there is no way for the rivet supplier to fulfill your requirements and you want to facilitate that order, then you either have to increase your budget or lower your requirements for quality. Projects are different, and so are the requirements for quality. This needs to be your own

The last thing is that you need to find a reliable rivet manufacturer. Of course, it is not easy to find a reliable rivet manufacturer the first time. You may talk to more than one rivet manufacturer or supplier. If you want to buy open end blind rivets from a reliable rivet manufacturer, please contact us.

Conclusion

Through this post, I believe you have gained an in-depth understanding of open end blind rivets. Including its definition, structural composition, working principle, installation steps and advantages and disadvantages. This information is very important to you if you want to buy Open End Blind Rivet. This article will give you a better understanding of the type of open end blind rivets and information you want to buy.

Use high quality open end blind rivets to complete your project! The initial investment may be a little more, but the benefits will far outweigh the investment! An unrivaled secure connection is not to be

Order High Quality Open End Blind Rivets from Rivmate

Are you looking for reliable Open End Blind Rivet manufacturers?Rivmate is one of the top Blind Rivet manufacturers and suppliers in China. If you want to buy a large quantity of open end blind rivets, you can place your order with us!

Whether you want to buy 50,000pcs or 5,000,000pcs, we can well provide them for you! You can also provide drawing information to us, our engineers will provide solutions according to your drawings.