Tri Fold Rivets

Rivmate stands as one of China’s leading manufacturers of Tri Fold Rivets, operating its own production facility with a comprehensive quality control system. All critical processes—from raw material selection and cold heading forming to final inspection—are completed in-house.

Finish Your Project with Rivmate Tri Fold Rivets

At Rivmate, you will get high quality, satisfying tri fold rivets.

5/32″ Tri Fold Rivets

3/16″ Tri Fold Rivets

1/4″ Tri Fold Rivets

Aluminum Tri Fold Rivets

Tri Fold Exploding Rivets

Rivmate: China Tri Fold Rivets Manufacturer Near You

If you are seeking a reliable Chinese manufacturer and supplier of Tri-Fold Rivets (flower-type/tri-fold hollow rivets), Rivmate is a trusted choice. As a fastener manufacturer with our own production facilities, we have long specialized in the R&D and mass production of structural hollow rivets. We provide stable, verifiable product solutions for diverse application scenarios.

Rivmate offers tri-fold rivets in multiple specifications and materials to meet industry-specific requirements for material types, assembly thicknesses, and load conditions. Additionally, beyond tri-fold rivets, we supply waterproof Bulb Tite Rivets for applications demanding sealing and water resistance.

Beyond rivet products, Rivmate provides complementary installation tools to ensure consistent deployment and uniform installation quality during Tri Fold Rivet assembly. From rivets and rivet nuts to self-clinching fasteners, we deliver comprehensive fastening system solutions that minimize selection risks and enhance overall assembly efficiency for our customers.

Custom Tri Fold Rivets Make Your Business More Successful

Various Specifications Available

We are proud to show you our different sizes of tri fold rivets. you can buy it in bulk at the most affordable price.

Tri Fold Rivets with Waterproof Function

Rivmate can provide tri fold rivets with different features depending on the needs of your business. including waterproof tri fold rivets with rubber gaskets.

Definition

What are Tri Fold Rivets?

Tri Fold Rivets are structural pop rivets specifically designed for soft, thin-walled, or low-load-bearing materials. During installation, the rivet tail forms a three-way expansion structure, significantly increasing the load-bearing surface area. This effectively distributes the load, reducing the risk of material tearing or failure. This characteristic makes Tri Fold Rivets particularly stable in plastics, composites, sheet metal, and sandwich structures.

HOW TO CHOOSE

Why Choose Rivmate Tri Fold Rivets?

Tri fold rivets are perfect for joining brittle materials (e.g. plastics, composites, fiberglass, carbon fibers) to flexible materials (e.g. rubber, leather, fabric, etc.). As a top manufacturer of tri fold rivets in China, we are able to manufacture various kinds of high quality tri fold rivets.

At Rivmate, you will get perfect, stunning tri fold rivets.We can offer a wide selection of tri fold rivets. Due to the unique design of tri fold pop rivets, it can effectively disperse the stress evenly and avoid material damage.

We manufacture tri fold rivets in different sizes, materials and features. you can choose from our tri fold pop rivets and waterproof bulb tite rivets. all materials and sizes are available with us.

All of our Rivmate tri fold pop rivets are compounded with stringent international certifications such as DIN, ISO and IATF 16949, so you can be sure that all Rivmate tri fold rivets are of the highest quality performance. Unlike many other Chinese rivets manufacturers, Rivmate has built up a good reputation in the global market and won wide recognition from customers for its high quality products and reliable services.

If you intend to order tri fold rivets from us, there is no need to worry about the quality. For your order, we will provide you with samples of tri fold rivets before placing the order in bulk. Make sure that our tri fold pop rivets can fully meet your requirements.

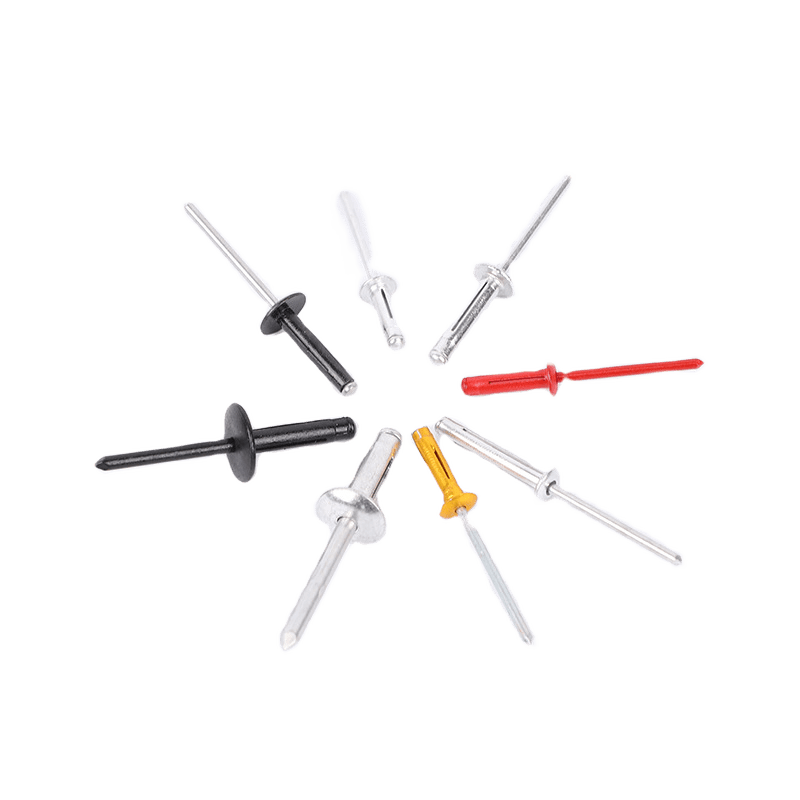

In addition to tri fold rivets, we can also produce various types of blind rivets, rivet nuts and self clinching fasteners.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

How Strong

How Strong are Tri Fold Rivets?

Assessing the strength of Tri Fold Rivets cannot simply apply the evaluation criteria for structural rivets. The design objective of Tri Fold Rivets is not to pursue the highest tensile or shear values, but to achieve safer, more reliable connections in brittle or soft materials. Therefore, their “effective strength” is more reflected in the distribution of stress rather than the ultimate load itself.

Based on actual test data, taking the common aluminum Tri Fold Rivet (4.8 mm / 3⁄16″) as an example, its typical shear strength typically falls within the 600–1,000 N range, while tensile strength generally ranges around 400–800 N. Specific values depend on the clamping range and substrate conditions. For the 6.4 mm (1⁄4″) size, shear strength increases to approximately 1,200–2,000 N. While these figures are significantly lower than those of structural Monobolt Rivets, they fully meet design requirements for plastic and composite applications.

The true advantage lies in the structural mechanism. After installation, the tail of the Tri Fold Rivet forms a tri-directional expansion structure, with the backing support diameter typically reaching 2.5–3 times the original rivet diameter. This significantly reduces stress per unit area. According to engineering mechanics principles, when the stress-bearing area increases threefold, local contact stress theoretically drops to approximately 33% of the original value. This is precisely why Tri Fold Rivets effectively prevent tearing in plastics and fiberglass.

It must be emphasized that Tri Fold Rivets are not suitable for high-load metal structures. For applications requiring resistance to high shear, vibration, or dynamic fatigue loads, Monobolt Rivets or Lockbolts should be prioritized in engineering. However, in scenarios where material protection, assembly stability, and long-term reliability are primary objectives, Tri Fold Rivets often outperform standard Blind Rivets—representing an engineering strength advantage.

Working Principle

How Do Tri Fold Rivets Work?

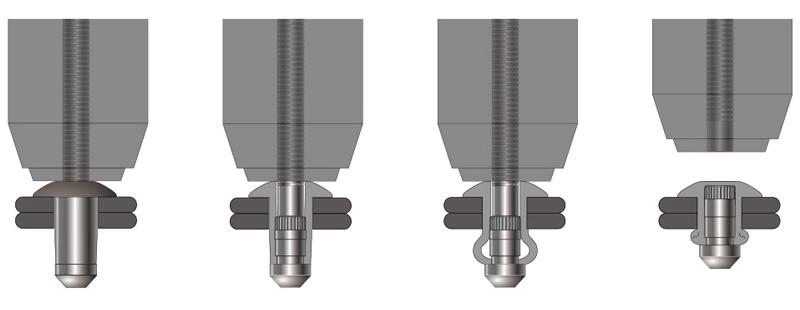

Basic Working Principle

Tri-Fold Rivets achieve connection through controlled deformation. During installation, the rivet gun pulls the mandrel, causing the rivet tail to undergo plastic deformation along a pre-set groove. This forms a three-directional expansion structure, establishing stable support on the back of the base material.

Three-Fold Expansion Mechanism

Under tension, the rivet tail splits into three symmetrical support arms that fold outward. The expanded backing support diameter typically reaches 2.5–3 times the original rivet diameter, significantly increasing the load-bearing surface area.

Load Distribution Advantage

The enlarged contact area substantially reduces stress per unit area. Engineering applications can lower localized contact stress to approximately 30–40% of the original value, effectively preventing tensile cracking or tearing in plastics, fiberglass, and composite materials.

Mandrel Break and Locking

When tensile force reaches the preset threshold, the mandrel fractures at the predetermined break zone. This action locks the tri-fold structure to the substrate’s backside. The rivet head and expanded tail work together to generate clamping force, achieving a stable connection.

Tri Fold Rivets vs Bulb Tite Rivets

Which is Better, Tri Fold Rivets or Bulb Tite Rivets ?

| Comparison Item | Tri Fold Rivets | Bulb Tite Rivets |

|---|---|---|

| Expansion Structure | Three-leg fold-out expansion | Bulb-shaped, uniform expansion |

| Backside Bearing Area | Large, segmented support area | Very large, continuous bearing area |

| Load Distribution | Good load spreading through three legs | Excellent load spreading through full bulb |

| Suitable Materials | Plastics, composites, fiberglass, thin sheets | Plastics, composites, thin sheets, soft materials |

| Gap Closing Ability | Moderate | Excellent |

| Hole Filling Performance | Good | Very good |

| Pull-Out Resistance | Good in brittle materials | Very high in soft or oversized holes |

| Waterproof Capability | Limited (non-sealing) | Excellent (especially closed-end versions) |

| Typical Applications | Appliance housings, panels, lightweight assemblies | Automotive trim, HVAC, outdoor enclosures |

| Cost Level | Generally lower | Generally higher |

Tri-Fold Rivets are better suited for cost-sensitive applications requiring protection of brittle materials. Their triple-fold expansion structure significantly increases the backing support area and effectively distributes loads, thereby reducing the risk of tearing in plastics, fiberglass, and composite materials.

Bulb Tite Rivets derive their core advantage from their bulbous continuous expansion design. Upon installation, they form a complete bulge, delivering greater back-side contact area and superior hole-filling capability. This makes them particularly effective in scenarios with significant hole tolerance variations, unstable assembly gaps, or where waterproofing performance is critical.

Order Tri Fold Rivets Now

If you would like to order or customize tri fold pop rivets, please be sure to contact us!

At Rivmate, you can take care of all your pop rivet sourcing needs at once. You can provide us with drawings and our factory will provide you with samples and quotes based on the drawings.

For customized tri fold rivets, you can contact us now.

FAQs – Tri Fold Rivets

1. What Are Tri Fold Rivets Used For?

Tri Fold Rivets are primarily used to join brittle or low-load-bearing materials such as plastics, composites, fiberglass, and thin sheet structures. Their tri-fold expansion creates a large support area on the reverse side, significantly reducing the risk of material tearing or punching through. They are particularly suitable for housing components and lightweight structural applications.

2. How Do Tri-Fold Rivets Work?

During installation, the tail of the tri-fold rivet undergoes plastic deformation along a pre-cut groove, forming a three-way expanded support structure. This structure distributes the load across a larger back surface area, improving stress distribution and enhancing the safety and stability of the connection within brittle materials.

3. Are Tri Fold Rivets Stronger Than Standard Blind Rivets?

In high-load metal-to-metal applications, the ultimate strength of Tri Fold Rivets typically does not exceed that of structural pop rivets. However, in plastics and composites, their “effective joint strength” often surpasses standard Blind Rivets. This is because the tri-fold expansion structure better protects the substrate, reducing the risk of premature failure.

4. Can Tri-Fold Rivets Be Used for Waterproof Applications?

Standard Tri-Fold Rivets are not primarily designed for waterproofing. For applications requiring high sealing integrity, it is generally recommended to select Bulb Tite Rivets or employ auxiliary solutions such as sealing washers and sealants. Whether waterproofing requirements are met should be verified based on the specific structural design.

5. How Do I Choose the Right Size of Tri-Fold Rivets?

When selecting rivets, focus on the clamping range, rivet diameter, and the type of materials being joined. The clamping range must cover the total assembly thickness, diameter determines the basic load-bearing capacity, and material type affects the expansion effect. Before mass application, it is recommended to conduct actual assembly tests to confirm the optimal specifications.